When adhesion failure becomes apparent in manufacturing processes, it can seem to come out of nowhere. Very often, there is no problem until suddenly there is. It feels unpredictable, unavoidable, and like the best solution is to either eat the loss it brings or just hope it goes away as quickly and surprisingly as it arrived.

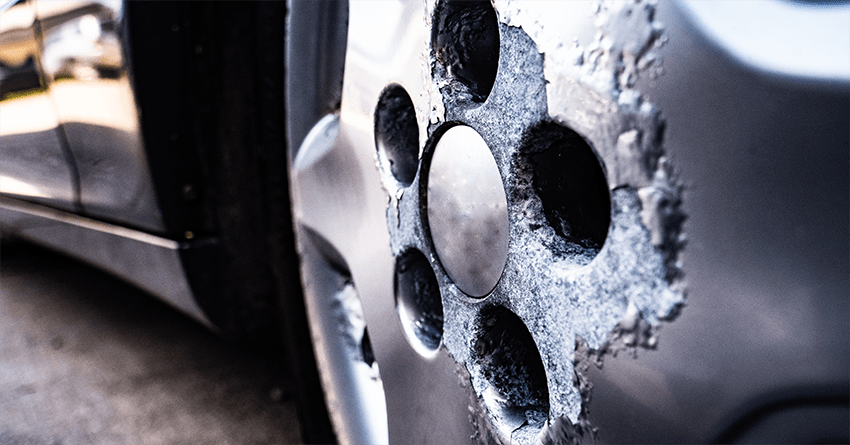

Adhesion failure comes in the form of the print not sticking to a plastic bottle or label, delamination of film, a coating not uniformly applied on a medical device or electronics component, cracking of a sealed gasket, gold wire bonds not holding, paint chipping and fish-eyeing, nutplates and fasteners coming loose from their holdings, and many many more. Some of these result in scrap and waste at the production level. Others can result in recalls and returns, while others have major safety and public health implications.

However, the failure manifests, and whatever the consequences, manufacturers have an imperative to design and control their processes so that these failures do not occur.

Is that even possible?

It absolutely is. By applying the following principles and steps, all manufacturers--regardless of their industry, application, or whether they are experiencing adhesion failure currently or not--can reliably predict whether their production process will produce adhesion failure or not and can solve the problem at the root cause.

3 Things to Control to Ensure Reliable Adhesion

Whether bonding, sealing, coating, printing, laminating, or painting, there are always three fundamental elements that the entire adhesion process hinges on. Control of these elements engenders certainty that the adhesion process will be successful.

1. Composition of the adhesive or coating

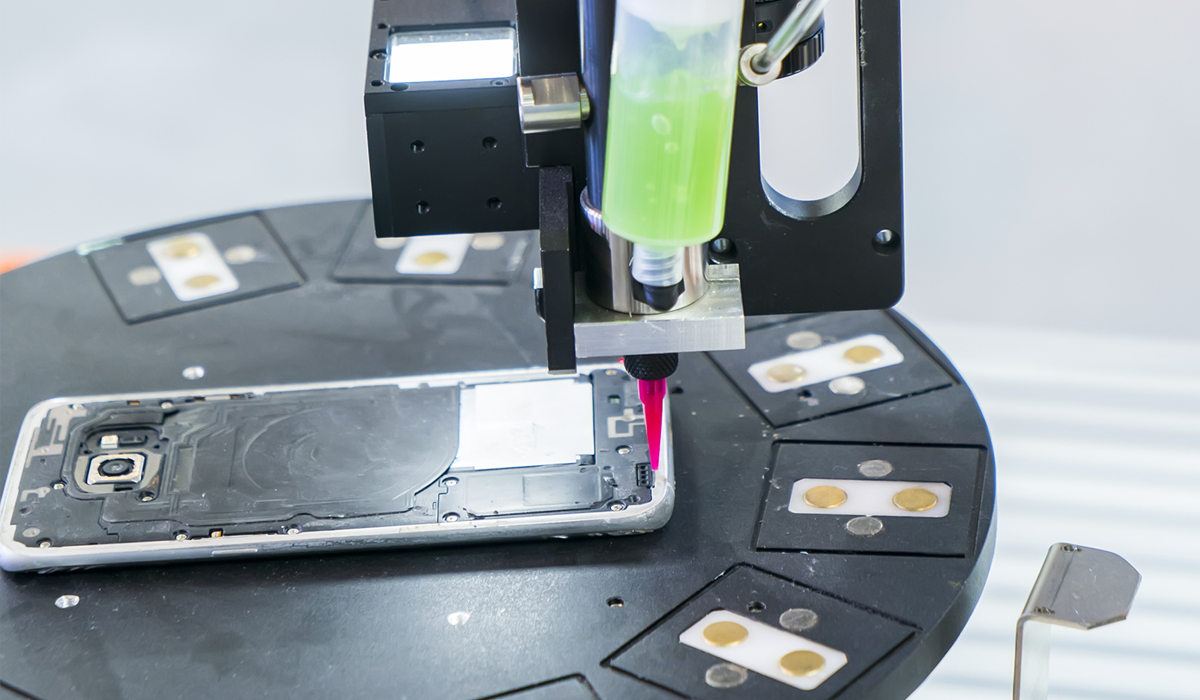

2. Curing and application process

3. Quality of the material surface

Adhesives and coatings involved in these processes are well understood and are designed to be as effective as possible. This is also true for curing and application operations. Manufacturing teams at all levels look at those two factors very closely and take great pains to employ the best options available.

The third element, the quality of the material surface, is the least understood and, therefore, the least controlled. This leads to the next principle of adhesion process control to gain predictable adhesion.

Rethink your adhesion manufacturing processes with Surface Intelligence.

The Science of Adhesion Process Control

The primary principle to know about adhesion is that it is a chemical process. It is a common fallacy to assume that the roughness of a material surface is the most crucial characteristic to guaranteeing adhesion. If the surface chemistry is not well-managed and fashioned to be precisely what is required for the application, then the roughness of the surface is a moot point. Adhesion will not be successful if the chemistry is not correct.

There are many ways to alter the surface chemistry of a material. Every time a surface is cleaned, treated, or even just sitting around in the middle of a production facility, the surface is fundamentally changed. With cleaning, the surface that is most amenable to adhesion is revealed by removing things like oils and particulate from the top of the material. With treatments such as plasma, corona, and laser ablation, the chemical bonds on the surface are broken, and what is left is a chemically reactive surface, ready to be bonded with an adhesive or coating.

The terms surface quality and surface cleanliness need to be used in reference to the chemical state of the material surface because that is the characteristic that determines whether adhesion is going to be successful or not.

Identify and Measure Surface Quality at Every Critical Control Point

Critical Control Points are every point in the entirety of an adhesion process where the material surface has an opportunity to be altered in any way, intentionally or not, and for better or worse. Critical Control Points are found in every production process, and each one has a crucial role in the lifecycle of a component that will be bonded or coated, or cleaned.

Some Critical Control Points are common and obvious. It is easily assumed that an industrial part washer, a manual isopropanol wipe, a media blasting step, or plasma treatment would be considered a Critical Control Point. What is not often thought of as places where material surfaces can be altered is the facility of the parts supplier and the storage areas within the manufacturing facility.

Parts and components can arrive at a manufacturing facility with vastly different surface chemistries and, therefore, are beginning the adhesion process from widely varying starting points, quality-wise. Inconsistency at the forefront that is not dealt with ensures inconsistency throughout the entire process.

Time in storage at any point in the production process can have dramatic effects on a material's surface.

If the storage time comes post-cleaning or treatment, then the freshly prepared surface can degrade based on several factors:

- what the material is

- what kind of cleaning or treatment was done

- how long the item is in storage

- what kind of container or environment the part is housed in during storage

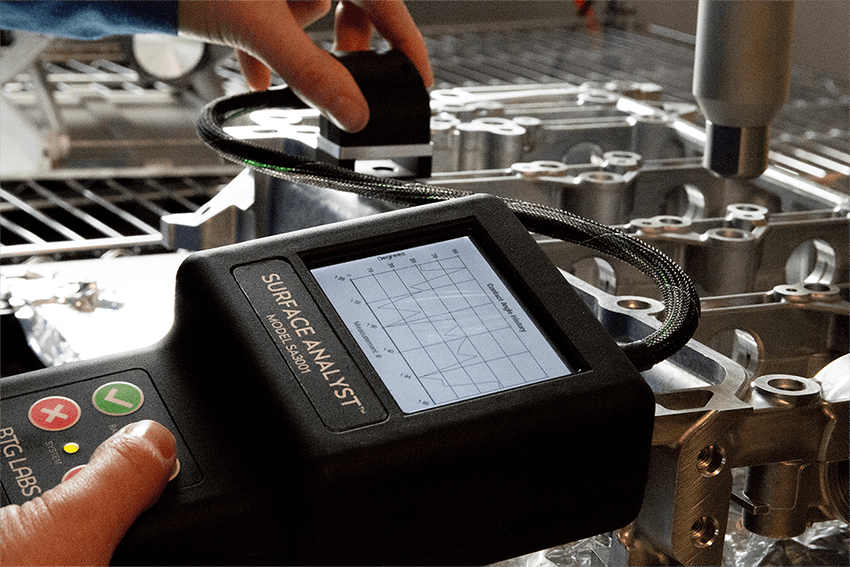

Identifying Critical Control Points in an adhesion process can only happen when it is understood that the surface quality is tantamount to the surface chemistry. When it is discovered that this chemistry changes at certain points, then that point needs to have a surface quality measurement step implemented before and after. This measurement needs to be quantitative, objective, non-destructive, and able to be conducted at the actual point on the production line where the surface is being altered. Measuring the surface before a Critical Control Point allows manufacturers to know precisely what kind of surface they are manipulating. Measuring after each Critical Control Point gives clear data that the surface was changed and by how much.

Continually Monitor all Critical Control Points

Building certainty into the manufacturing process begins by identifying and analyzing adhesion process Critical Control Points. There are many variables in every production process that can affect adhesion, and not all of them are always apparent. If measurements are being done before and after every Critical Control Point, then anomalies will be spotted quickly, and root cause analysis and remediation can begin at once.

Optimize the power of next-gen connectivity with data & surface intelligence.

Tracking changes in surface quality means surprises can be diagnosed immediately, and predictability can be maintained.

If all of these principles and methods are implemented fully and with the proper understanding and equipment, then manufacturers will create and sustain reliable adhesion processes that result in adhesion success like they’ve never seen before.

Adhesion is not a magic trick. There is a rigorous science behind it which makes it controllable and repeatable.

For more information on developing a consistent and reliable adhesion process, download the “Predictable Adhesion in Manufacturing Through Process Verification” ebook.