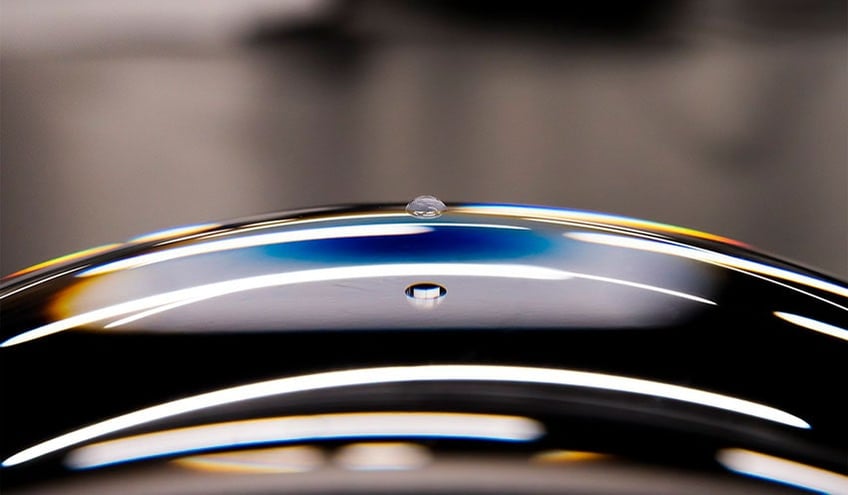

Historically, accurately measuring contact angles on concave and convex surfaces has been a challenge. The typical method used to measure contact angle on these types of surfaces has been with a benchtop goniometer. The challenges arise from the way goniometers measure contact angle—from a horizontal view. A concave material prevents a clear visual of the horizon line needed to determine the contact angle. Because of this, the closest a user could get to measuring contact angle on a concave surface was to use a flat coupon (sample) of the same material and hope that the actual material surface has the same surface quality as the sample. While this would offer insight into the surface energy of the material, it would not be exact because it wouldn't be the actual part of manufacturing.

A Unique Design to Measure Contact Angle on Parts with Complex Shapes

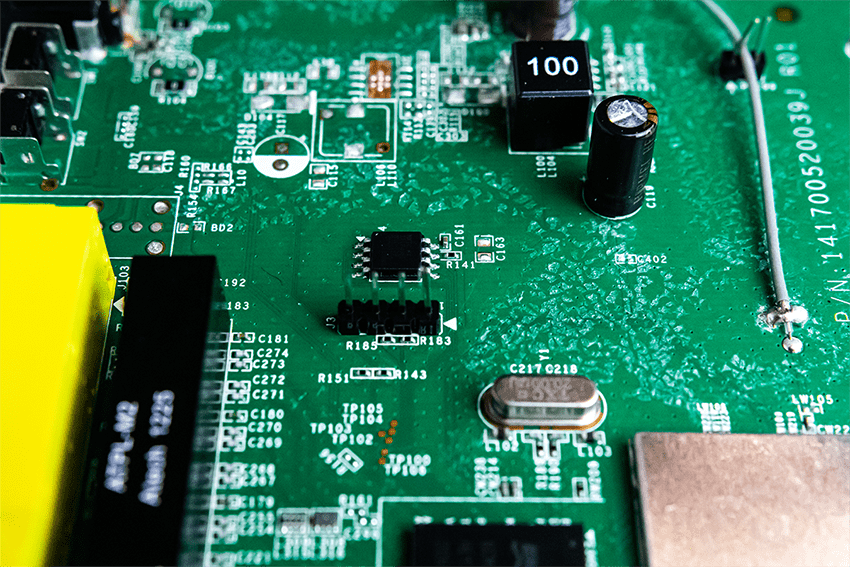

The reality is that manufacturers produce complex products that involve a large variety of material types, shapes, and sizes. In order for contact angle to be a reliable method to determine surface quality, an innovative approach needed to be developed.

The Surface Analyst™ has been designed to precisely measure contact angle on these complex surfaces: vertical, horizontal, up-side-down, smooth, rough, and mirrored. Examples include: validating coatings on optical lenses, packaging cylinders, verification of coatings on automobile headlights, cleanliness checks inside of industrial processing tanks, and many more. Our custom-made inspection attachments, fixtures, and Quality Check Stations provide the stability needed to ensure surface quality inspections are as fast, easy, and accurate as possible, without exception.

Rethink your adhesion manufacturing processes with Surface Intelligence.

Watch the Surface Analyst in Action

Take a look at this video that demonstrates how the Surface Analyst is able to measure contact angle on these material surfaces.

Do you have a current or an upcoming project that could use surface quality validation via contact angle? Check out the custom solutions that the Surface Analyst provides that allow manufacturers to control the challenges that come with complex-shaped products and surfaces.

Struggling with adhesion failures? Been there. Solved that.

Learn how you can utilize contact angle in the development of new products, to control supply chain issues and monitor manufacturing processes. Download the eBook, "Brighton Science's Guide to Adhesion Science for Flawless Manufacturing."