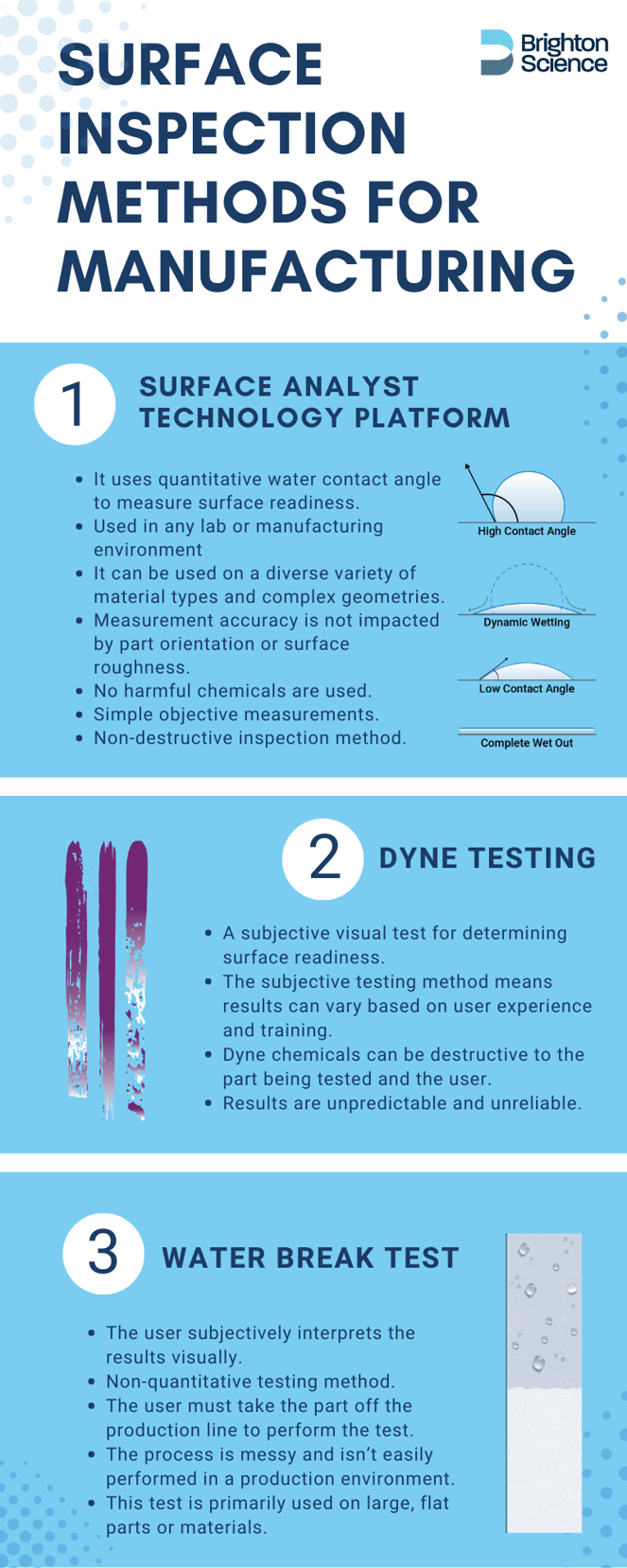

In the manufacturing industry, it is crucial to meet certain surface preparation requirements in order to ensure the safety and reliability of products. Various tests have been developed to determine if these requirements are being met and if the cleaning process has been effective enough to promote strong adhesion for coating, bonding, sealing, printing, or painting. In this infographic, we will compare the approach of the Surface Analyst with two commonly used surface preparation methods found in manufacturing industries across the board.

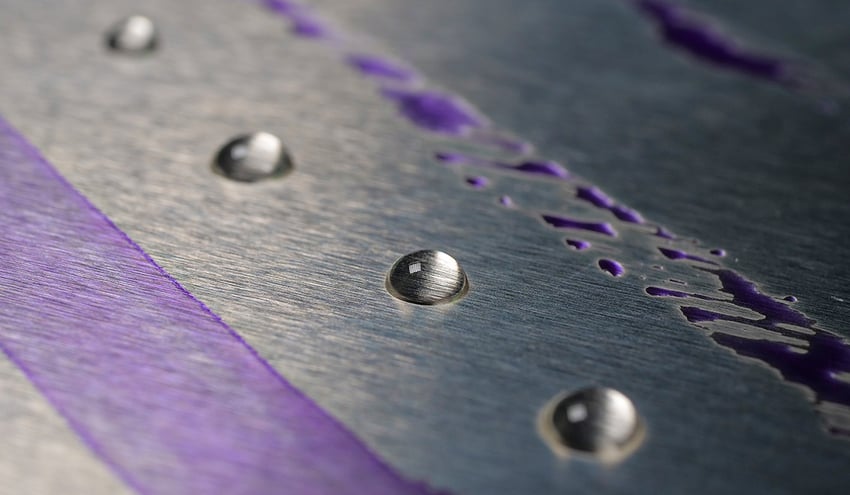

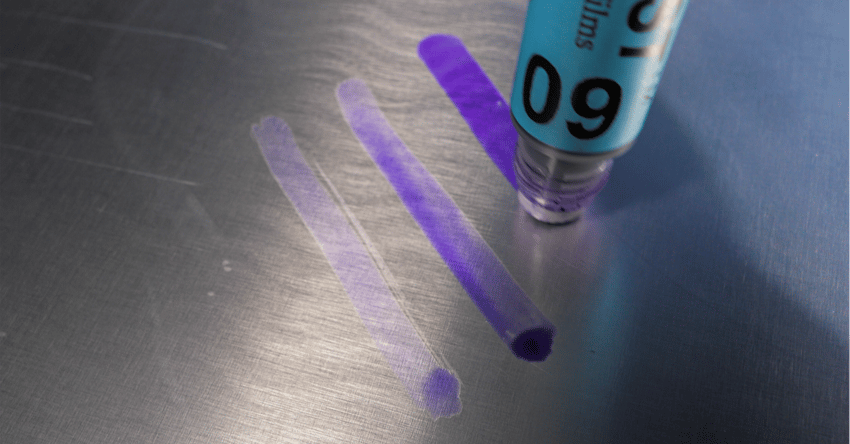

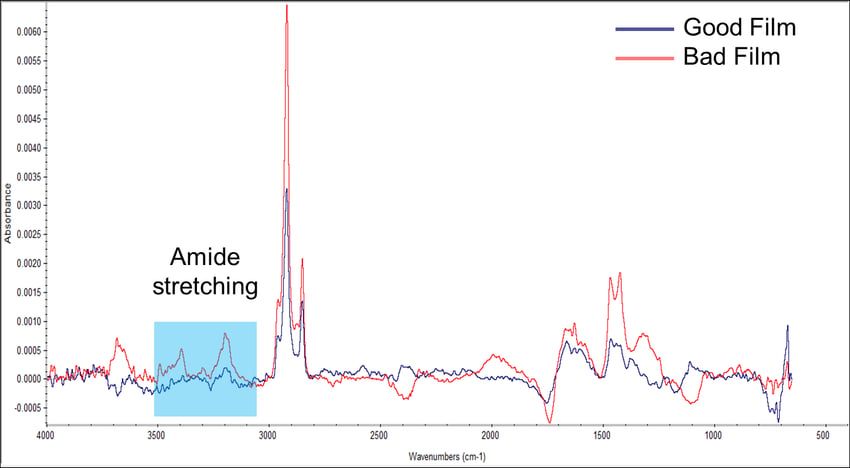

Legacy inspection methods such as dyne ink/solutions and water break tests have been traditionally employed to assess surface preparation. However, these methods suffer from subjective evaluation, unrepeatable procedures, and numerous other weaknesses that ultimately make them unreliable.

The Surface Analyst offers a more advanced and accurate approach to surface preparation testing. It provides objective measurements and quantifiable data, eliminating the need for subjective evaluations. This not only improves the reliability of the testing process but also ensures consistent results that can be replicated.

By utilizing the Surface Analyst, manufacturers can have confidence in their surface preparation processes, knowing that they are meeting the necessary requirements for safe and reliable product manufacturing. This innovative technology offers a superior alternative to legacy inspection methods and brings a new level of precision and reliability to surface preparation testing.

Rethink your adhesion manufacturing processes with Surface Intelligence.

In conclusion, the Surface Analyst has revolutionized surface preparation testing in the manufacturing industry. With its objective measurements and reliable data, it replaces outdated and unreliable methods like dyne ink/solutions and water break tests. Manufacturers can now depend on accurate results that ensure product safety and reliability.

To learn about the top alternative to dyne testing, download the eBook "What is Dyne Testing? Enhance Precision and Effectiveness with the Ultimate Alternative to Dyne Testing."