The evaluation of material surfaces in terms of quality has long relied on dyne testing. Despite their drawbacks, such as subjectivity, imprecision, damage to surfaces, and safety risks for users, dyne tests have remained popular among manufacturers due to their wide availability and affordability. However, these tests do little to prevent or address adhesion failures in a manufacturing environment.

In this article, we will explore the concept of dyne level, its significance and limitations, and the reasons why it is worth reevaluating the practice of dyne testing.

What is a Dyne Level?

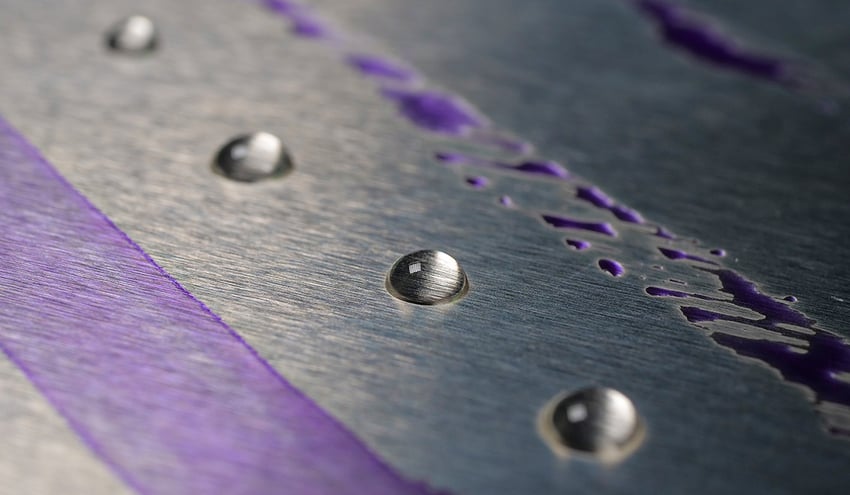

Manufacturers across many industries often use dyne testing to try and estimate the surface energy and predict the adhesion properties of the materials they work with. What dyne inks actually measure is something called the ‘wetting tension’ of the surface. The wetting tension is the surface tension of a liquid that just wets out (i.e., stays spread out as a continuous film) on a surface without retracting and breaking up into droplets. The wetting tension of a surface is related to its surface energy. The units of wetting tension are dyne/cm, the same units as the surface tension of liquids and the surface energy of solids. Higher levels of wetting tension indicate greater wettability, which typically correlates with better adherence of adhesives, coatings, paints, and inks to the substrate.

In manufacturing settings, dyne testing is widely employed for examining materials prior to adhesion procedures such as bonding, sealing, coating, painting, and printing. It is also commonly utilized to verify the quality of material surfaces following surface treatment processes like corona treatment, flame treatment, and plasma treatment. Sometimes dyne testing is used in an attempt to evaluate cleanliness by determining if contaminants are present or not.

What Does a Dyne Test Tell You (or Not)?

Dyne inks are intended to be sensitive to the surface energy of a surface, which correlates to the ability of an adhesive or ink to bond well to the surface. The surface energy can be thought of as a measure of how reactive a surface will be to an ink, coating, or adhesive. It’s important to remember that dyne inks measure the wetting tension of a surface, not the surface energy, but the wetting tension can be close to the surface energy.

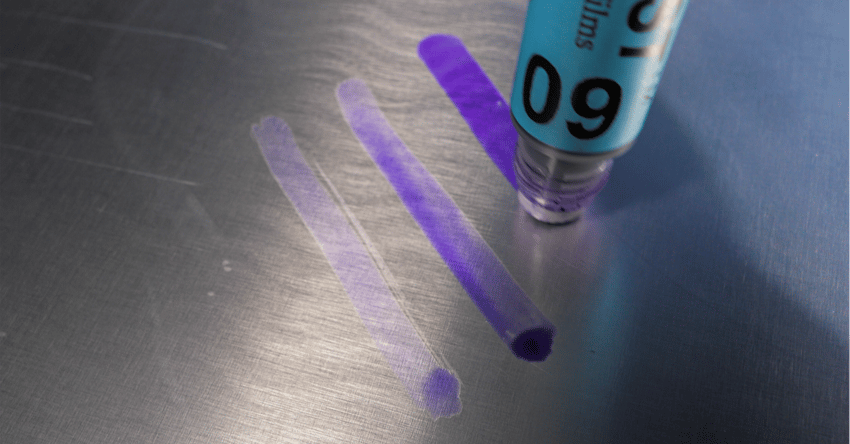

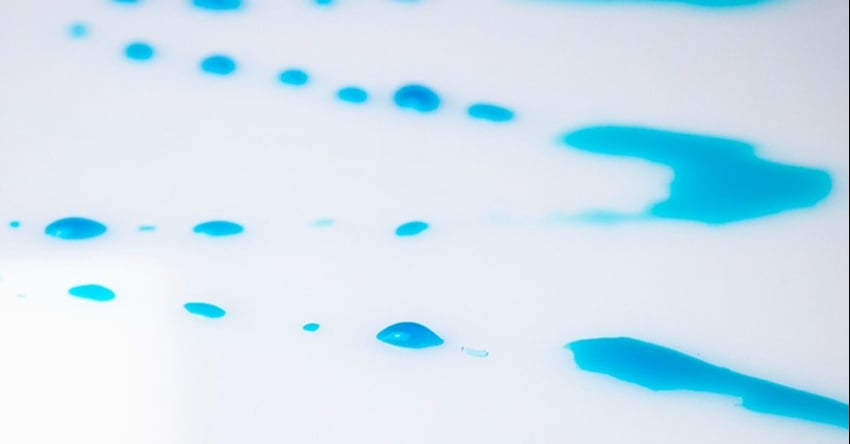

Dyne inks are provided as a series of liquids with a range of surface tensions. The ink is applied as a thin film to about 1 in² of the surface from a cotton swab or a felt-tip pen. If a given ink beads up within two seconds of application, its surface tension is higher than the wetting tension of the surface, and the test is repeated with a lower surface tension ink. The lowest surface tension ink that stays spread out for at least two seconds is defined as the wetting tension of the surface.

Typical dyne ink uses include research, product and process development, and process monitoring. The portability of dyne allows for use on the factory floor or in the lab, but this method is very limited.

What are the Drawbacks of Dyne Testing?

- Dyne solutions testing is a subjective pass/fail assessment that relies on the user’s ability to interpret the results. Dyne ink testing can’t pass Gage R&R evaluations due to the subjective, semiquantitative nature of the measurement. Interlaboratory studies show that agreement between labs and operators is rarely better than ±4 dyne/cm and often as high as ±10 dyne/cm.

- Dyne inks contaminate the material it's used on, so usually, the test is performed on a sample of the material or product that can be discarded. This means this test method is slow and creates wasted product and material.

- Health concerns: The chemicals used in dyne inks are VOCs ("volatile organic chemicals"). Most contain 2-ethoxyethanol and Violet 28, as well as formamide, which are considered hazardous by the 2012 OSHA Standard (29 CFR 1910.1200). These substances have been known to cause cancer, may damage the fertility of an unborn child, and may cause damage to organs through repeated exposure if swallowed.

- The ASTM D2578-84 and ISO 8296 standard test methods for dyne testing only recommend the use of dyne testing procedures on polypropylene and polyethylene film and sheeting. The final outcome of the measurement on other materials is said to likely be inaccurate. Using dyne tests on materials other than these particular plastics should be studied comprehensively prior to use.

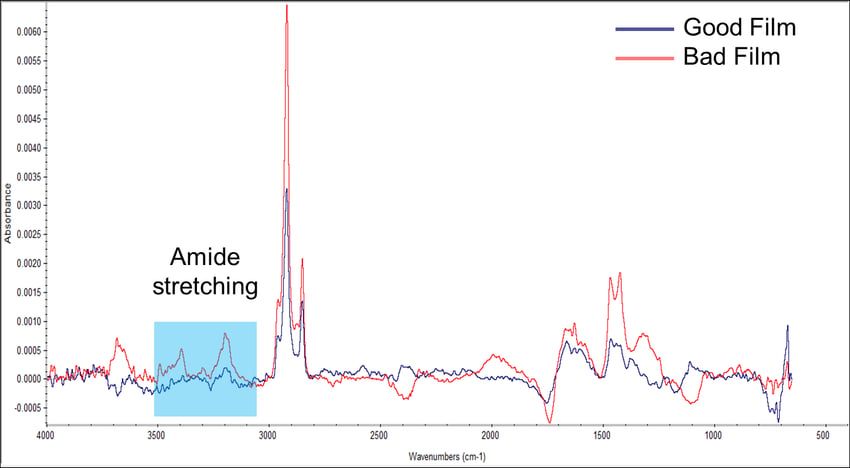

- Many film manufacturers include lubricants (slip agents) in their polymer formulations to reduce friction on the film as it passes through processing equipment and surface treatment with corona treatment. Slip agents are great at reducing friction but can also act as contaminants by interfering with adhesion. Because slip agents are soluble in the components of dyne inks, dyne inks, and dyne pens tend to dissolve these agents and not detect their presence. A material that has slip may "pass" a dyne test but show adhesion failures when printing or laminating.

Unfortunately, dyne testing has quite a few drawbacks as a surface measurement method. It doesn’t constitute an objective, quantifiable surface measurement; it contaminates the parts being tested, it is insensitive to soluble contaminants, and it can expose the user to harmful substances.

Watch the Video: Water Contact Angle vs. Dyne Inks in Manufacturing

Tools Used to Measure Dyne Levels

Dyne pens and dyne test fluids are used in evaluating the wetting tension (not surface energy) of substrates. Each pen or bottle is filled with ink formulated to a specific surface tension level.

Get hands-on with your surface cleanliness with the Surface Analyst 5001.

Determining a Substrate’s Dyne Level

- If contaminants are suspected, thoroughly clean the substrate before testing.

- When using dyne pens, draw the marker across the substrate’s surface in a line. When using inks and cotton swabs, saturate the swab and wet approximately 1 in² of the surface. Too thick or too thin of a film will lead to erroneous results; practice will show the right amount.

- Note the time until the liquid beads up. If greater than 2 seconds, repeat with the next higher surface tension dyne fluid.

- The wetting tension (sometimes called dyne level) of that specific substrate is the highest surface tension dyne ink that stays spread out for at least 2 seconds.

This video demonstrates dyne ink applied to a metal surface. As you can see, it can be very difficult to determine how the ink is interacting with the material surface.

What is a Good Dyne Level?

A surface's ability to adhere to paints and glue improves with higher dyne levels or increased surface energy. This means that achieving a higher dyne level is preferred by most ink manufacturers. It is widely recommended to maintain a minimum dyne level of 40 dynes/cm.

However, it is also stated by suppliers of dyne testing inks and solutions that it’s critical to determine the appropriate dyne level for each material through experimental results obtained from functional finished product testing.

Understanding the Impact of Surface Quality

Manufacturers must have a solid understanding of the surface energy of their parts in order to anticipate how well the surface will perform in terms of painting, sealing, coating, printing, bonding, and sealing.

Failure to possess this knowledge leaves manufacturers vulnerable to significant risks, including inconsistencies in surface quality, adhesion failures, wastage, and even product recalls. To learn more about dyne testing and the number one alternative to this method, read the eBook “What is Dyne Testing?