Applications

Surface Cleanliness & Contamination Control

Invisible Contamination Causes Visible Failure

Adhesion and coating processes depend on something you can’t see: the chemical condition of a surface. Success happens at the molecular level—when the first few layers of the surface are clean and ready to interact with adhesives, coatings, or treatments. Even trace contaminants like oils, silicone, flux, or solvent residues can block those interactions, quietly undermining performance and leading to production delays, field failures, or costly recalls.

To eliminate that uncertainty, you need tools and processes that detect, validate, and monitor surface contamination in real time—so you can be confident your surfaces are chemically clean and built for success.

Why Surface Cleanliness Matters

You can’t fix what you can’t see. Cleaning processes may appear consistent, but variables like handling, storage, batch-to-batch variability, or cleaning agent residue can result in undetected contamination. And that contamination matters—because adhesion and coating success happens at the surface’s first few molecular layers. If those molecules are occupied by oils, silicones, or other residues, they block critical chemical interactions and compromise performance.

Traditional methods—like water break tests or solvent wipes—are subjective, time-consuming, and don’t catch the full picture. That’s why leading manufacturers turn to Brighton Science to bring clarity to their surface quality. Whether you're qualifying new cleaning systems, validating process changes, or preventing adhesion failures, our solutions make invisible risks visible—and solvable.

Common Uses:

- Validate cleanliness of parts before bonding, sealing, or coating

- Detect invisible residues like silicone, oil, flux, or solvent that compromise adhesion

- Evaluate batch-to-batch cleaning consistency on automated lines

- Measure surface energy to qualify and optimize cleaning processes

- Develop inspection protocols to meet surface cleanliness specifications

How Brighton Science Helps

Brighton’s Surface Intelligence platform and tools deliver fast, non-destructive insights into chemical cleanliness and surface readiness—right at the point of process. Our technology goes beyond visual inspection and cleanliness assumptions, helping teams:- Identify contamination before it causes defects

- Refine cleaning processes for maximum consistency and efficiency

- Implement real-time surface quality checks in production

- Build traceable cleanliness validation into process qualification

Who Benefits

Surface cleanliness impacts every stage of product development, production—and even the services that support them. Here’s how different roles and providers can use surface intelligence to solve problems, prevent failures, and improve outcomes.

Quickly identify invisible contaminants, fine-tune cleaning systems, and add traceability to process decisions.

Prevent line stops, reduce first-pass yield failures, and ensure compliance with cleanliness specs.

Avoid variability and field failures caused by surface contamination, and validate compatibility with coatings or adhesives during design and testing phases.

If your company provides cleaning systems or bonding services, our tools help you prove performance, troubleshoot issues remotely, and deliver value your customers can see.

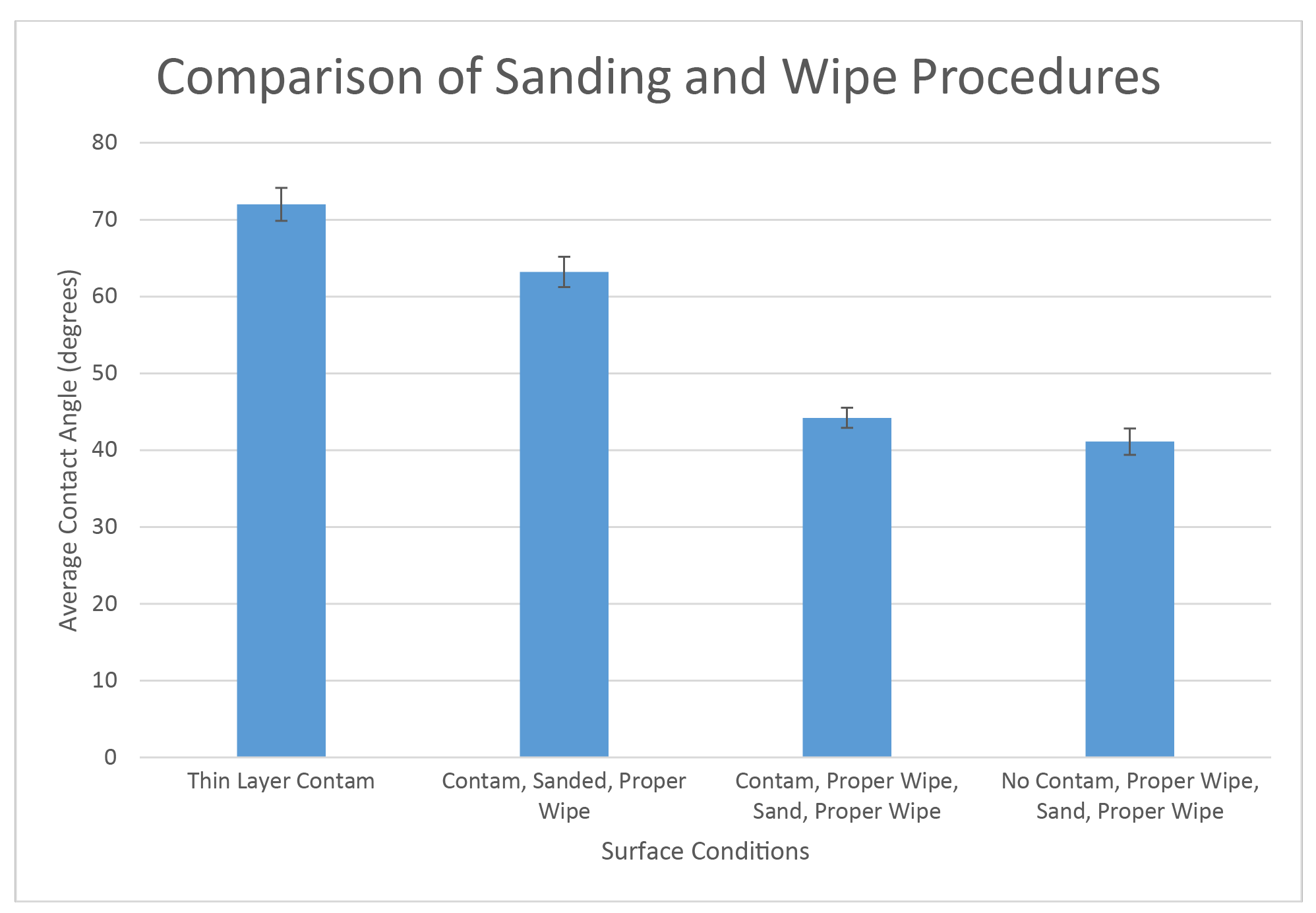

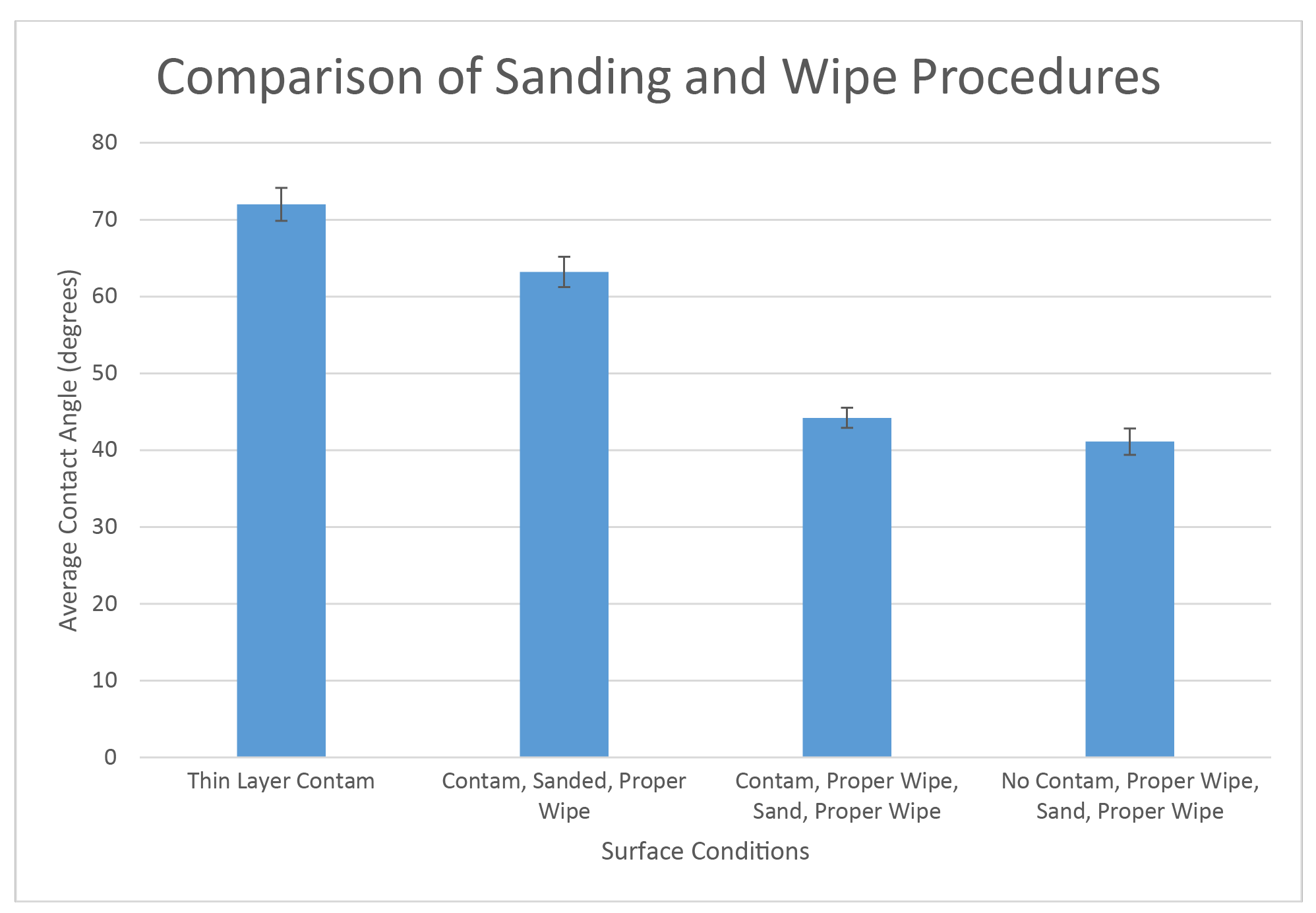

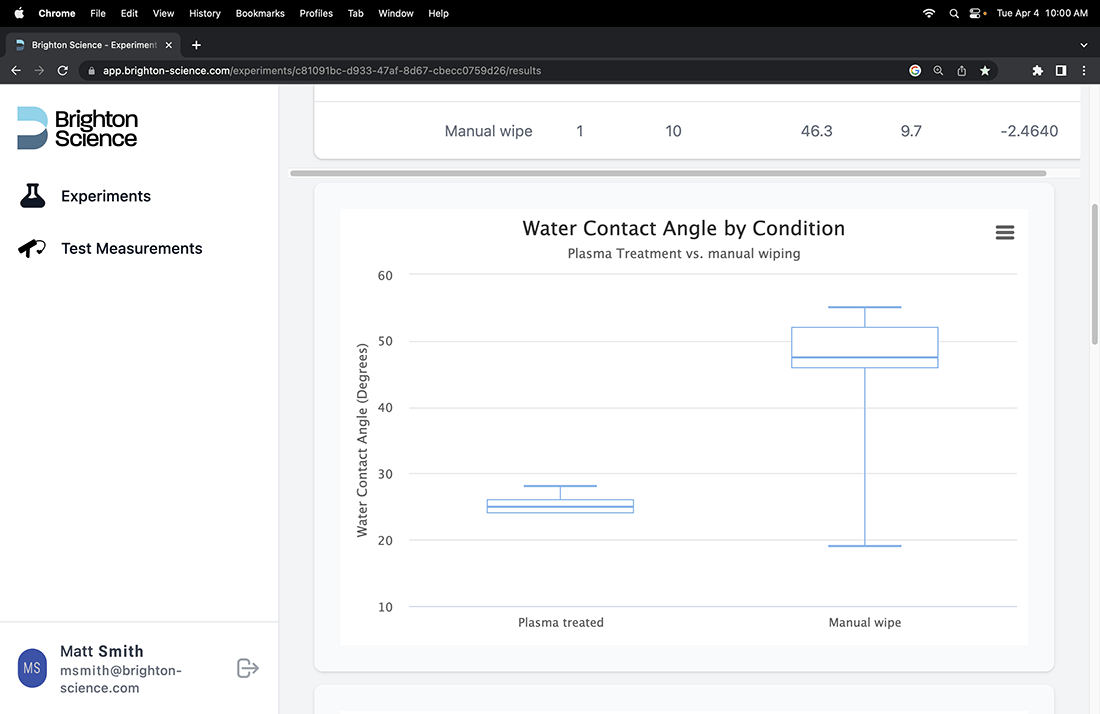

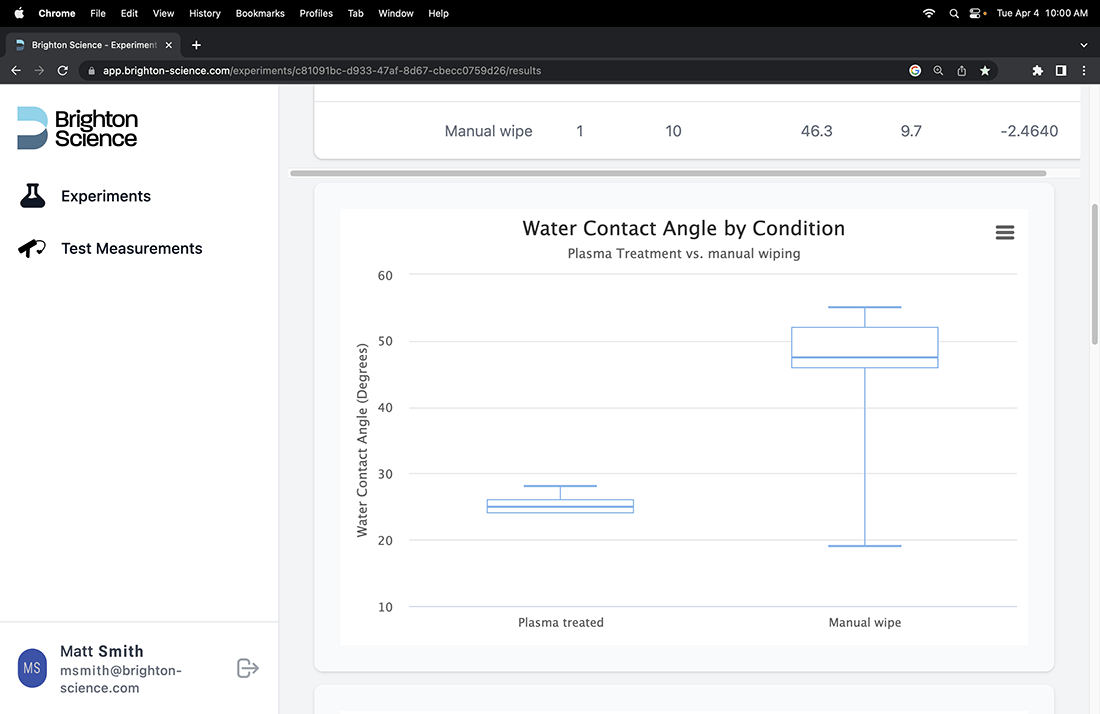

.png?width=1000&height=1500&name=chart-and-title%20(1).png)

.png?width=1000&height=1500&name=chart-and-title%20(1).png)

Our Customers

.png)

.png)

.png)

.png)

.png)

Unmatched educational resources to expand your knowledge and understanding

Brighton Science is the global leader in surface intelligence.