Key Takeaways

- Materials science connects chemistry, physics, and engineering to explain how atomic and molecular structure drives real-world material performance.

- Material properties determine what products are possible, from aircraft and medical devices to consumer electronics.

- Technological progress is often limited by available materials, not by lack of ideas.

- Modern product development depends on precise control of material behavior, especially for bonding, coating, and surface-dependent processes.

- Understanding materials science early in design reduces risk, improves reliability, and prevents costly late-stage failures.

- Advances in surface measurement have expanded what manufacturers can reliably build, enabling wider adoption of composites, adhesives, and advanced materials.

Many people are not familiar with the subject matter and discipline of materials science because it’s not taught in elementary or high school and only infrequently at the university level. Instead, we are often taught chemistry and physics. Chemistry teaches us how atoms and molecules interact, while physics studies the forces and laws of nature that govern interactions of matter and energy. But there must be something that ties these two together—the interactions of atoms to form molecules, the interactions of molecules to form other molecules, and the interactions of large collections of molecules to determine the properties of a material.

The properties of a material are also the properties of every physical thing we use and interact with daily. Tying together the molecular-level structure to the macroscopic properties of objects is where materials science comes in. Understanding this discipline can be the key to unlocking a new perspective for engineers who are developing new products.

What is Materials Science?

The field of materials science is the study of materials with a focus on their composition, structure, and properties. The interdisciplinary field combines physics, chemistry, and engineering and encompasses all-natural and artificial materials. This includes metals, ceramics, glasses, polymers, semiconductors, and composites.

Optimize the power of next-gen connectivity with data & surface intelligence.

A "material" is a collection of many atoms or molecules, where the collection typically behaves differently than the individual parts. For example, when one or a few water molecules behave chemically similar to the molecules in a glass of water, but the few molecules are not a liquid, they don’t flow and exhibit viscosity or surface tension. These are properties of large collections of molecules and are examples of properties of a material that depend on the collective interaction of many molecules or atoms. Understanding and predicting material properties requires understanding the behavior of individual atoms and molecules and the behavior of large collections of these components. Materials scientists can use this understanding to develop new materials following a list of desired properties.

A great example is gold. As an element, it has distinct chemical properties; however, when a few thousand gold atoms are combined to form a thin gold foil, it exhibits collective behavior that a single gold atom cannot. The collection of gold atoms can be bent, stretched, or hammered to form objects that retain their shape and show new properties that make gold a useful substance, like heat and electrical conduction. Properties like electrical conductivity and malleability are material properties, i.e., properties of large collections of atoms. Single atoms and molecules cannot exhibit these properties.

Materials Science is a Crucial Discipline

Why do we care about materials? To put it simply, they are the foundation of our civilization. Look at how we name the ages of societal evolution after the materials they had to work with: the Stone Age, Bronze Age, Iron Age, and now the Computer Age (made possible by semiconductors, a distinct class of materials).

In the Stone Age, humans only had materials like stone, wood, and leather. The knowledge of metal processing led to huge leaps in civilization; imagine farming without an iron plow. The steady increase in food production through these advancements helped pave the way for more differentiation of labor and the growth of large towns and cities.

Technology has always been limited by the materials available to allow ideas to take physical form. The limit to technology has never been a lack of creative ideas for new designs. Instead, it's finding the right materials to make those ideas into a physical reality. Galileo’s notebooks contained drawings of a lovely helicopter. What were the most advanced materials Galileo had to work with? Probably paper and rope, maybe iron. It would have been nearly impossible for Galileo to build a helicopter with the materials available to him at that time.

Fast-forward to England in 1791, when John Barber was granted a patent for the first jet engine. Limits on the properties of available materials meant the project had to wait until the 1930s, nearly a century and a half later before metals of sufficient strength, temperature, and wear resistance were available to build a practical jet engine.

Materials science is a crucial discipline because it lies at the nexus of chemistry, physics, and engineering. It empowers designers and engineers to realize their new ideas for electronics, medical devices, machines, and more.

The Impact of Materials Science

Iron replaced wood in shipbuilding starting in the 1840s, which cut costs and space provided by the iron hull over wooden ones. In the latter half of the 19th century, steel replaced iron, which lightened the load and increased cargo capacity. However, after welding technology began to replace riveted construction at the outbreak of World War II, the lack of a thorough understanding of materials' properties led to many ships breaking in half and sinking.

The discovery by Constance Tipper of Cambridge University that the fractures were due to the steels of the time becoming brittle at the low temperatures in the North Atlantic Ocean led to the development of the science of fracture mechanics, which has led to tremendous advances in our ability to understand and control materials properties.

This branch of materials science has allowed for continuous improvement in the strength and toughness of materials, resulting in lighter, stronger, more efficient structures like ships, automobiles, and aircraft.

Aircraft Construction

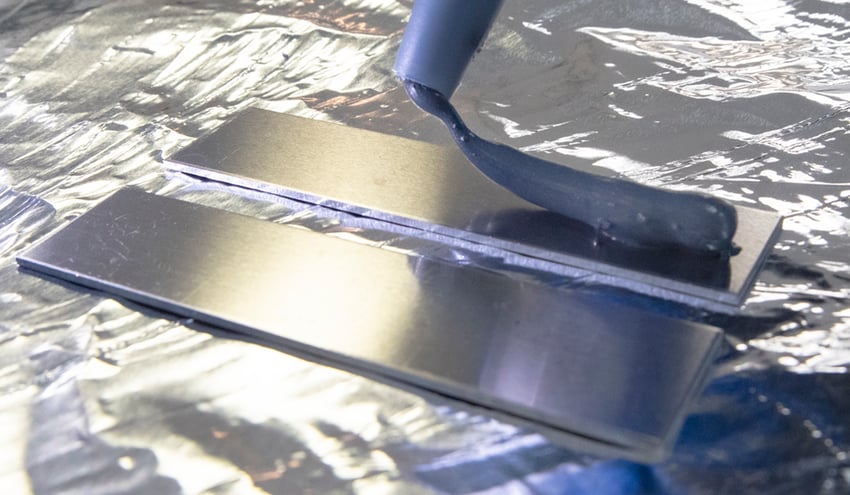

Aircraft manufacturers have invested heavily in building strong materials from carbon fiber-reinforced plastics (composite materials), which have much improved strength-to-weight ratios over metals like aluminum. The traditional way of assembling an aluminum aircraft involves mechanical fasteners: bolts and rivets. These fasteners work well with metals, which have some ductility. However, drilling a bolt hole in a composite material creates microscopic cracks that can weaken the whole structure. Aircraft design can’t effectively utilize the great properties of composite materials without using adhesives to assemble the structures. This comes with some significant challenges for a high-risk product. Unfortunately, the quality of a bond cannot be determined by inspection after the bond is made.

A ‘bad’ bond looks the same as a good one.

Currently, the only way to check the quality of a bond after it’s been made is by a proof test. A proof test puts the structure at a higher stress level than expected to confirm it can be withheld. This is not practical. If you detect a bad bond after the structure is built, it’s too late. Because of poor bond quality, reworking a bonded aircraft wing or fuselage costs millions of dollars.

As a result, composite materials have seen slow adoption in aircraft design because of the limitations of our ability to create reliable adhesive bonds.

In the late 1990s, materials scientists from Brighton Science stepped in and took on the challenge of understanding the required factors to create a high-quality adhesive bond. The concept was to determine how to measure and control the parameters that control bond quality so that the probability of ever making a bad bond vanishes.

This work, funded by the US Air Force and the State of Ohio, helped birth to surface measurement technology innovations that have resulted in more efficient and cost-effective aircraft manufacturing. The same technology is now being used in almost all manufacturing areas to ensure reliable bonding, coating, cleaning, and adhesion.

How Materials Scientists are Innovating New Materials to Enable New Products and Processes in Manufacturing

At its core, materials science is understanding the macroscopic behavior of materials based on their atomic and molecular structure. With this understanding comes the ability to design, control, and predict material properties.

Materials scientists study macroscopic phenomena in the world, developing a fundamental understanding of them and, from there, seeking to improve some aspect, e.g., optical properties, sustainability, or high strength combined with low weight.

Why does a car crumple a particular way in a collision? Why did the metal bend that way? How can we make a metal absorb more energy to protect the car's occupants better during a crash? Can we create a new aluminum alloy or a fiber-reinforced plastic to replace the steel that can absorb even more energy in a collision while also creating a lighter, more fuel-efficient vehicle?

What Happens if Product Development Teams Lack an Awareness of Materials Science?

Without awareness of materials science in product development, design freedom is limited by designers who stay rooted in existing materials technology. For example, if the new reality of reliable bonding processes is not considered, new advances in materials and design cannot be used.

Reliable bonding is crucial to many other industries besides aerospace, for example, in the miniaturization of consumer electronics. You can't have a compact and slim smartwatch assembled with screws; it just wouldn't be possible to manufacture. The manufacturing of articles like this depends on the scientist's ability to measure and control the composition of the bond surfaces to be successful. Medical devices likewise depend on the controlled surface properties of the construction materials. Imagine a knee replacement bonded to the bone using adhesives failing after a year due to an imperfect surface preparation process. Understanding the materials science of processes like adhesive bonding will result in higher performance, higher reliability levels, and ultimately, better-designed products.

What Can Businesses Do to Gain Awareness and Place the Appropriate Importance on Materials Science?

Businesses need to be aware of materials science during all product design and manufacturing phases. Many organizations don’t have dedicated materials scientists on staff or an understanding of important materials science concepts in design and manufacturing, but there are opportunities to work with companies that have this expertise.

After cleaning the surface, a company often sees a design drawing that says to bond two parts together. But what is "cleaning?" A materials scientist understands that there are many different cleanliness levels, each appropriate to different end-uses. Processes like adhesive bonding require a level of cleanliness that can be difficult to achieve and even more difficult to measure without special equipment and techniques. Because the designer lacked this insight and had no materials scientist looking over their shoulder to ensure appropriate specifications for surface preparation, the reliability of this bond will be very suspect.

Businesses must gain awareness of the importance of materials science for product design and manufacture. By doing so, they can avoid potential issues and optimize their products.

Summary

Materials science is a critical element in the development of new products. The discipline lies at the intersection of engineering, physics, and chemistry and is crucial for advancing product design and manufacturing. Materials science expertise can help manufacturers create higher-quality products with unique properties that give them an edge over competitors.

A better understanding of materials science can also lead to more efficient production processes, saving time and money. For businesses, investing in materials science research and development can be the key to success in today’s marketplace.

At Brighton Science, we offer consultation services with materials science expertise at every stage of the design and manufacturing process. We will help you resolve potential issues before they happen, ensuring that your product is manufactured to the highest quality standards.

Frequently Asked Questions

Q: What is materials science in simple terms?

A: Materials science studies how a material’s structure, from atoms to bulk form, determines its properties and performance. It helps explain why materials behave the way they do and how to design better ones.

Q: Why is materials science important for new product development?

A: Because product performance, durability, manufacturability, and reliability are all limited by material behavior. Understanding materials science helps teams select, design, and control materials before problems appear in production.

Q: How does materials science impact manufacturing reliability?

A: It enables manufacturers to predict and control properties like strength, adhesion, fracture resistance, and surface chemistry, reducing variation and preventing hidden failures.

Q: What role does materials science play in adhesive bonding?

A: Adhesive bonding depends heavily on surface chemistry and cleanliness. Materials science provides the tools to define, measure, and control those conditions so bonds perform reliably over time.

Q: Do companies need in-house materials scientists?

A: Not always, but they do need access to materials science expertise. Many organizations partner with specialists to define specifications, validate processes, and reduce development risk.

Q: How does materials science enable new technologies?

A: Breakthroughs like composites, semiconductors, lightweight alloys, and advanced coatings exist because materials scientists learned how to tailor properties at the molecular and structural level.

Download the eBook "The Advanced Guide to Transforming Product Development Through Surface Intelligence Data & Technology" to learn how your organization can leverage the power of materials science in product development.