Modern product development is fraught with challenges due in large part to the sophistication and complexity of the various elements that go into a final product – everything from materials and surface geometries to coatings, bonding, and even staff skills and competencies. Pitfalls await even the most fearless product development teams as a new product design passes through the various phases of product development: sample studies and proof-of-concept, prototyping, test builds, and full-scale production.

How Development Manages New Technology & Innovation

The challenges can be even more daunting as technology drives teams to seek new ways to improve products through lightweighting, better performance, miniaturization, and more streamlined production. This results in transitions to innovative new materials, adhesive material bonding, and advanced coatings. As product development teams dip their toes into these new technological waters, it’s becoming increasingly important for them to put into place product development processes and material selection protocols that will successfully and cost-efficiently address these challenges.

To better understand this developmental evolution, let’s take a closer look at the five basic steps of new product development:

1. Material Selection

Material selection is a multi-disciplinary task requiring the interaction of a variety of stakeholders, including product designers, material scientists, test engineers, and end-users. Each brings its own values and criteria to the material selection process to help narrow down the choices.

2. Bonding/Coating Evaluation

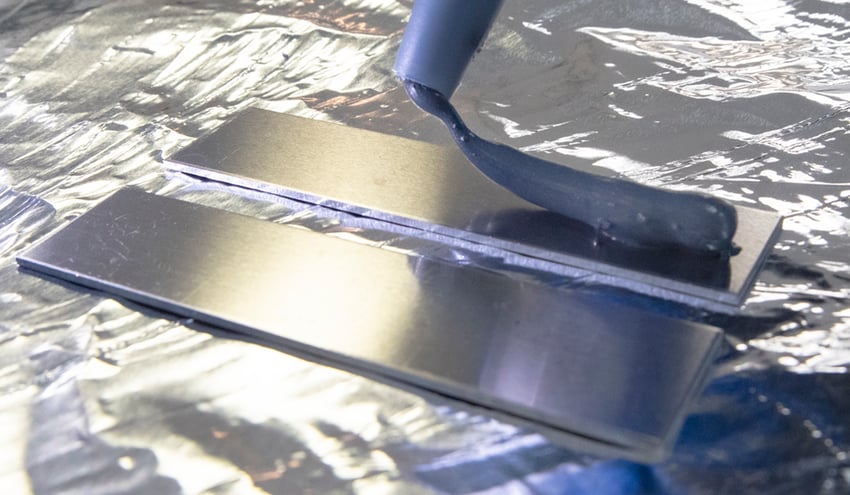

Materials under consideration are bonded or coated in a down-and-dirty test to assess their viability quickly. This is not meant to evaluate them accurately under real performance conditions or even using the correct geometry. It’s merely to see if the materials in question are compatible and to eliminate sub-optimal options.

3. Surface Preparation Review

Once the optimal material candidates are selected, surface preparation processes are screened in earnest to determine the best ways to clean and activate surfaces as part of a proof-of-concept for the manufacturing process. In some cases, Step 2 and Step 3 are performed simultaneously so that the optimal material and adhesion method offering the best-integrated performance characteristics are selected in accordance with the Design for Manufacturing (DFM) methodology. It’s important to note that in the process of selecting a material and surface preparation method, a joining process is determined. However, the manufacturing team may select a different material because of the effect of the actual manufacturing process on adhesion and the original selection.

4. Test Build and Qualification

In this phase, all the steps used to determine the materials and processes are repeated using the final choice of materials. The goal is to replicate the defined process and build the actual product with the final materials and sizes to ensure that everything performs as intended. However, there are still many challenges, including:

- Product performance requirements may have changed because actual geometries are more complicated, and the stresses on the product may now be different.

- Raw materials may be different from the original sample because they’re now formed or manufactured differently, or they’re coming from a different supplier.

- Surface preparation tweaks may be needed or, worse, changed completely because of the production scale required.

- Manual tasks create undesired process variabilities because worker experience or expertise is not adequate for the specific manufacturing tasks.

- The manufacturing environment is different; for example, prepared materials may sit too long to maintain surface quality in the manufacturing environment as compared to test lab conditions.

- Difficulty knowing what to change or fix if undesirable effects or characteristics pop up, degrading product performance, as product development transitions from proof-of-concept to test build and qualification.

5. Full Production

This, of course, is the final step in which actual products are rolling off the line at scale, ready for market. However, if for some reason the launch is not going as planned and a few product improvements need to be made in the test build phase, anxiety can get the best of engineering, and they might fall prey to adding surface preparation steps such as bump treatment, manual wiping, or plasma treatment without actually having the data that proves the need for them. As a result, complexity, cost, and operational steps are added unnecessarily without adding value to the product.

How to Address These Challenges

To gain control of all these variables, product development teams are creating digital threads that provide consistent surface quality data across the entire product development life cycle – from proof-of-concept through test build and qualification to full manufacturing. These digital threads are invaluable for providing insight into surface quality at every stage of development, using language common to the various teams so all stakeholders can quickly and easily grasp surface quality conditions and how they relate to product performance. As a result, any necessary improvements can be made quickly and efficiently to optimize product performance in a timely manner.

Rethink your adhesion manufacturing processes with Surface Intelligence.

Better Processes Produce Better Products

Having deterministic insight into surface quality throughout the entire product development process makes product launch cycles shorter and more predictable. It enables data-driven decisions to be made regarding design and process, allowing development teams to benefit from the principles of lean manufacturing.

It’s simple. Data drives product performance. Without having timely, appropriate, accurate, and consistent surface quality data throughout the product development process, you can only guess what changes or improvements need to be made. Successful product development means making changes that only improve performance and add value to the final product.

Learn how to properly equip your product development teams with the most up-to-date tools and knowledge to ramp up new products smoothly. Download our eBook to learn more: "The Advanced Guide to Transforming Product Development Through Surface Intelligence Data & Technology."