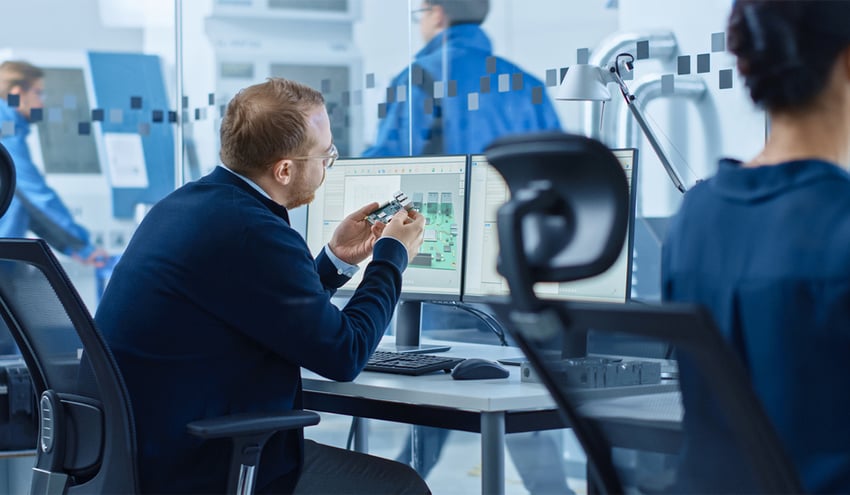

Roles matter. Everyone within an organization is responsible for producing the most excellent and reliable new products in manufacturing.

There is one downside to this - it can lead to siloed thinking. It can even discourage a common language between design teams and technicians dealing with real-world, in-the-moment challenges during the assembly process. New product development teams can overlook vital attributes of a build since they’re not involved in the process once it moves into manufacturing.

Oftentimes, new product development teams are removed from the actual manufacture and assembly of the new products they’re developing, also removing them from the problems that occur every day on the production floor. Unfortunately, this can give them a myopic view of what needs to be controlled in the development phase.

When critical aspects of the build (like material surfaces, for instance) are left up to chance, product management and manufacturing teams have to make downstream decisions that should have been specified from the beginning.

To bridge the gap between product development and product management teams, plus the rest of the manufacturing team, let’s look at five ways to increase surface intelligence at the earliest stages to guarantee more reliable products, lower risk, and higher production rates.

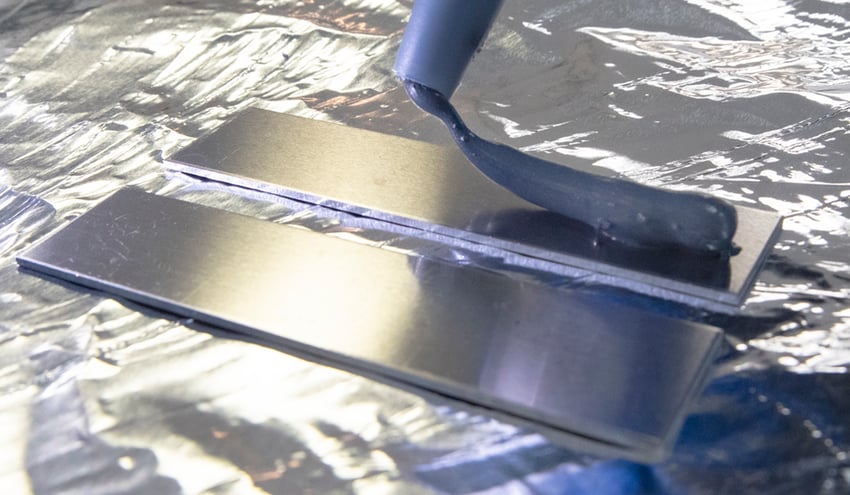

Rethink your adhesion manufacturing processes with Surface Intelligence.

1. Don't Look for a Silver Bullet

When product development challenges appear in the manufacturing process (and that’s most definitely a WHEN, not an IF), frequently, product design teams are roped in to troubleshoot the situation. To save time and money, these teams will likely look for a single, magic solution to fix the issue. But that's an unrealistic goal.

No universal solution can be applied once a problem like bonding failure occurs. Looking for that type of solution often leads to a costly process change: finding a new product or adhesive, adding primer, finding a different paint supplier, etc. These areas appear to be the most logical places to look to facilitate their bonding issue, but that’s because most teams are using incomplete data to determine the root cause of the problem.

Product development challenges actually occur because businesses don’t leverage tools and data around Surface Intelligence. Surface Intelligence allows product development teams to get to the root cause of the issue (a surface that has not been properly prepared for adhesion) and will enable them to do something about it to avoid issues altogether.

For example...

…say an automotive manufacturer is struggling to seal their car bodies properly. So, the materials engineering and product design team is asked to fix the problem. The team believes (based on gut feeling, not data) that the materials coming in from the supplier have subpar surface quality, but to meet the already delayed timeline of the product, they do not have time to switch suppliers.

So, instead, they assume their only recourse is to find a different adhesive that will perform 'better' with the surfaces the supplier is presenting them. They go through the arduous process of finding an adhesive that can ‘deal’ with the surface. Yet, the unexpected consequence of that adhesive is that it’s so weak it doesn't meet the overall structural performance requirements of the vehicle.

As a result, the company took two months to source a different adhesive instead of looking at the root cause - that surfaces coming in from suppliers need to be appropriately controlled and understood.

Setting a surface specification at the design phase would have established a standard that suppliers could be held to. But that would only be possible if product development teams understand the importance of surfaces when adjusting the product development process instead of looking for a cure-all after the fact.

2. There are Many Ways to Reach the Same End Goal

The mission of all product management teams is to make reliable products.

For teams to have confidence in the process they’ve designed, they need to know they have control over all the most critical elements. The key is to select the right way to create your surfaces and keep possible product development challenges minimal from the start; in essence, organizations must leverage Surface Intelligence.

Surface Intelligence allows product development teams to increase convenience, consistency, and confidence for their target audiences in the following ways:

- Design for manufacturability

- Gaining the ability to qualify suppliers while also holding them accountable for the quality of materials

- Select the appropriate preparation process that will complement the performance requirements of the adhesive, coating, paint, etc.

- Select the appropriate adhesive that performs well with your manufacturing environment, process, and material surfaces

Surface Intelligence aligns everyone involved in developing, designing, manufacturing, and supplying materials for building new products on the path to reliability and validation from consumers.

Using Surface Intelligence, teams can be in control of the story from the beginning using data, science, and engineering first principles, also known as the basics of how you want to design things.

3. Include Surfaces in DFMEA Reports to Make Everyone’s Lives Easier

Just like the end goal, surface management is everyone's responsibility, including product developers, because surfaces are vulnerable to change without warning. Suppose those responsible for developing new products treat surface quality like other high-risk components of the manufacturing process and do a thorough job defining surface quality specifications in the beginning. The results would be overwhelmingly positive. Everyone’s jobs downstream would flow smoothly, plus it would keep product launches on time.

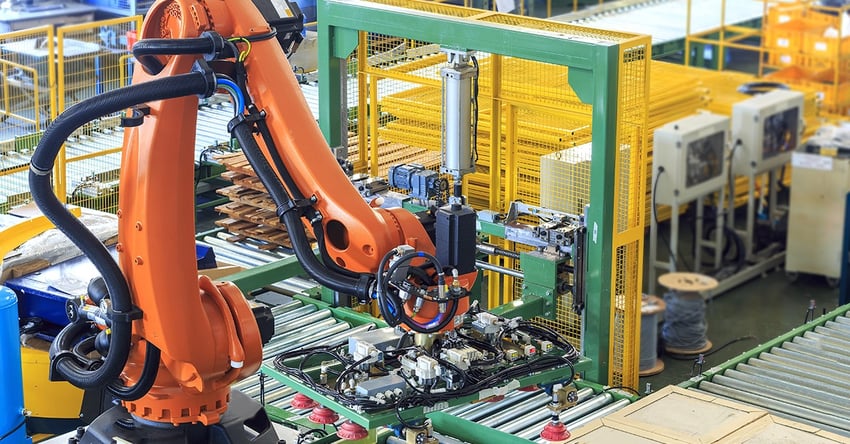

When product management teams can apply surface intelligence early on, it removes some of the pressure of responsibility from the assembly teams. Those in manufacturing don’t have the extra time or resources to understand, define and troubleshoot surface-related issues while building each new product.

Reliable surfaces come from quantifiable standards, common language, repeatable quality metrics, and a good design failure mode and effect analysis, or DFMEA. Including surfaces in your DFMEA reports makes the manufacturing team's job substantially easier.

But how do you begin that process? Well, it starts with a methodology adjustment within the product development team. They should strive for more than just checking boxes, i.e., “Does the design function?” or “Is it buildable?” even, “Is it meeting the deadline?”

Taking responsibility for the surface quality means teams are thinking beyond operations and are instead reaching for operational efficiency.

Applying Surface Intelligence at the design stage removes risks, unleashes innovation, enables team members to optimize key areas that need improvement, and releases tension between players at every step.

Revolutionize Your Manufacturing with Surface Quality Inspection Technology.

4. Surfaces can be the Difference Between a Successful or Unsuccessful Product Launch

There are an incredibly high number of variables that can impact surfaces in manufacturing - much higher than experts in product design might predict. So, how you organize and manage your supply chain, for example, or how you store parts prior to assembly, has a major role in how successful the end product will perform. And meeting product launch goals is all about controlling variables to mitigate surprises along the way.

A successful product launch determines not only the future of that new product but the future of the product development team and their place at the company. Will it lead to a slew of other products? Or will it fall flat and crumble? Surface Intelligence experts at Brighton Science can help increase the functionality of your product development teams, thus, increasing the functionality of each surface and each new product.

5. Suppliers are not Surface Science Experts

Turning to vendors who supply adhesives, surface preparation equipment, and components suppliers for surface intelligence expertise will leave your organization flying blind. Although 3rd party vendors have valuable knowledge and are specialized experts on their products and equipment, the reality is this: "surface science expertise" is not required to supply materials.

So, if surfaces are your issue, it only makes sense to employ Surface Intelligence experts.

As you partner with our experts, who have decades-worth of surface science research under their belts, they will reveal where and how to control your surfaces to get the precise results you’re working to achieve. As a result, you’ll begin to see your whole process differently.

Designing for Manufacturing is Always Tricky, but Surface Intelligence Helps Build Confidence

Designing for manufacturability is always a balancing act between the imaginative heights of innovation versus the organizational pressures, supply chain issues, and cost constraints that hold a design engineer back from being able to put their fantastic designs out into the world.

Leveraging Surface Intelligence allows team members to take advantage of the latest and greatest in materials and technologies without having to worry about withstanding the requirements.

Optimize the power of next-gen connectivity with data & surface intelligence.

Defining a surface cleanliness specification based on Surface Intelligence data will create alignment between everyone involved in the product lifecycle and will build the confidence necessary to take the innovative leaps organizations need to make the next great product.

Learn how your organization can leverage Surface Intelligence to transform how new products are developed by downloading the eBook "The Advanced Guide to Transforming Product Development Through Surface Intelligence Data & Technology."