Most engineers expect failures to trace back to obvious causes, a material defect, an operator mistake, or a process error. But sometimes the culprit is hiding in plain sight: silicone contamination.

Silicone is everywhere in modern manufacturing:

- Mold release agents in plastics and composites

- Lubricants and greases used in equipment

- Cleaning supplies that leave microscopic residues

- Personal care products worn by operators

- Even airborne particulates drifting through the workspace

Case Study 1: The Automotive Bumper Problem

One automotive supplier came to us with an unexpected failure. Their bumpers were consistently failing paint adhesion tests in production — sometimes peeling within days of application.

The engineers did what anyone would do:

- They swapped paint suppliers.

- They increased cleaning protocols.

- They even replaced equipment on the line.

But the problem persisted.

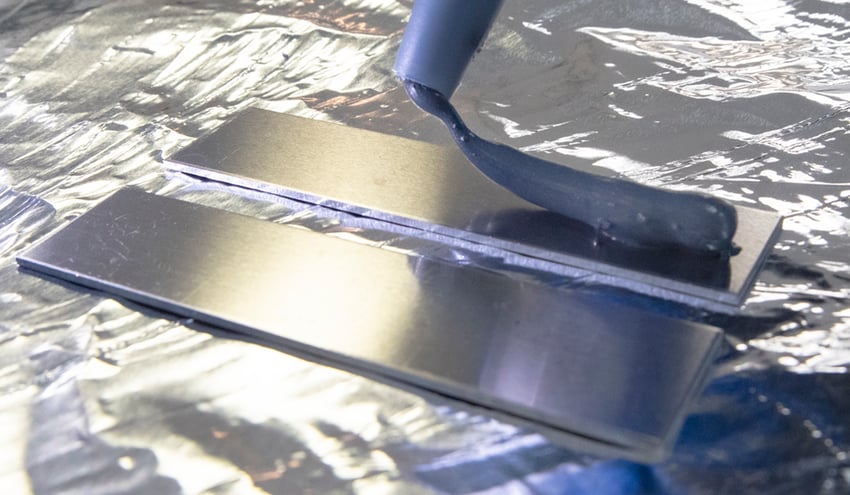

When we ran water contact angle (WCA) tests on the surface, the results showed contamination consistent with silicone. The source? A silicone-based mold release is used upstream in the bumper manufacturing process. Invisible to the naked eye, it was enough to prevent proper adhesion.

Once identified, the supplier switched to a non-silicone release agent and implemented regular surface monitoring. Paint adhesion failures dropped to zero.

For their team, the breakthrough was realizing the issue wasn’t bad paint or sloppy process — it was silicone hiding where they never thought to look.

Case Study 2: “Is Silicone in the Air?”

Another customer, in a highly regulated industry, worried that silicone aerosols from lubricants were migrating through the air and landing on critical parts.

To test this, we released a silicone aerosol under controlled conditions and measured surfaces at varying distances using WCA analysis.

Surface measurements show silicone contamination reaching multiple feet from the spray point within minutes. Angles >~60° are generally detrimental to the performance of coatings and adhesives.

Key Insight: Even without airflow, silicone contamination can travel up to 10 feet from its source in minutes.

This gave the client a clear picture: contamination wasn’t randomly floating around their facility, but in areas close to release points, parts were indeed at risk.

We also tracked how the contamination behaved over time. Initially, the silicone appeared as small, patchy droplets on surfaces. But over the next several minutes, these droplets spread and merged, forming an invisible, continuous film.

Key Insight: A surface that looks clean may still carry a thin layer of silicone—enough to interfere with coatings or adhesives. In other words, visual inspection alone isn’t reliable; even “clean” parts can be compromised.

This behavior illustrates why surface preparation and contamination control are so critical: silicone doesn’t just sit where it lands—it moves, spreads, and quietly creates problems that are invisible to the naked eye.

Why This Matters Across Industries

These two stories highlight the same truth: silicone contamination is rarely obvious, but it’s almost always disruptive.

- In automotive, a hidden mold release caused paint failures.

- In controlled environments, aerosolized lubricants raised concerns about airborne contamination.

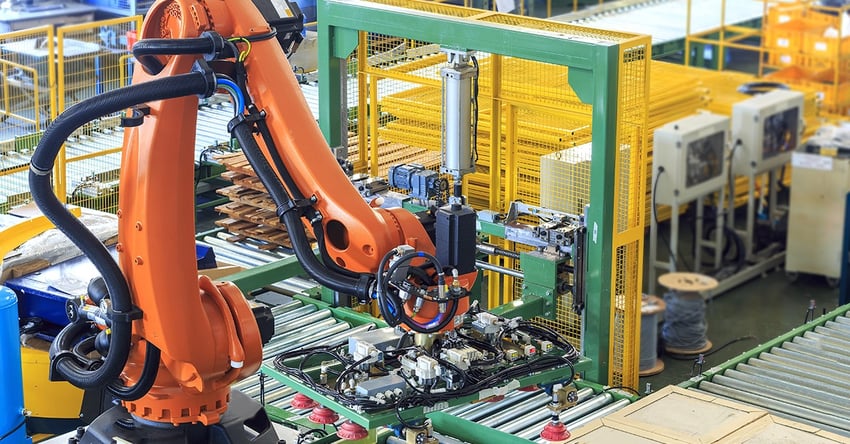

And across industries — from aerospace to electronics to medical devices — the same problem repeats:

- Failures appear inconsistent and unexplainable.

- Engineers spend days chasing the wrong causes.

- The real culprit turns out to be invisible silicone contamination.

The Takeaway

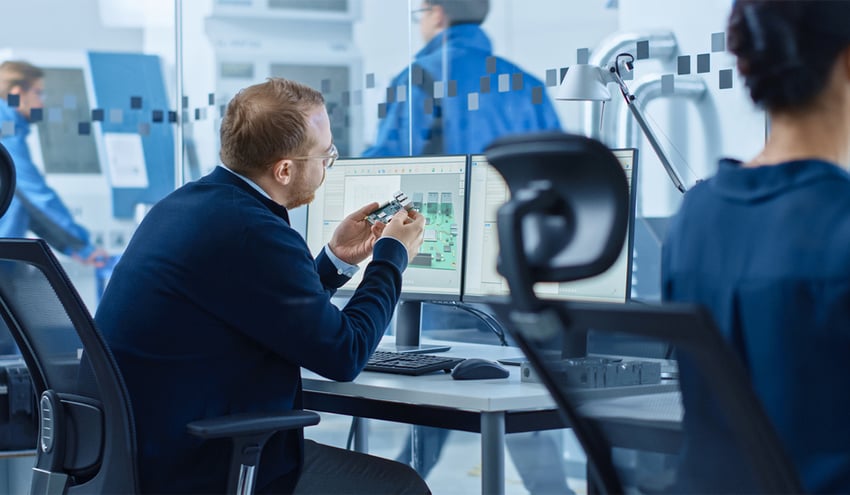

- Don’t assume surfaces are clean just because they look clean.

- Recognize that silicone can come from indirect or unexpected sources.

- Validate early using surface analysis tools before failures become costly.

At Brighton Science, we partner with engineers across industries to uncover hidden contamination issues and prevent them from derailing production.