Applications

Material & Supplier Qualification

Qualify the Right Materials. Trust the Right Suppliers.

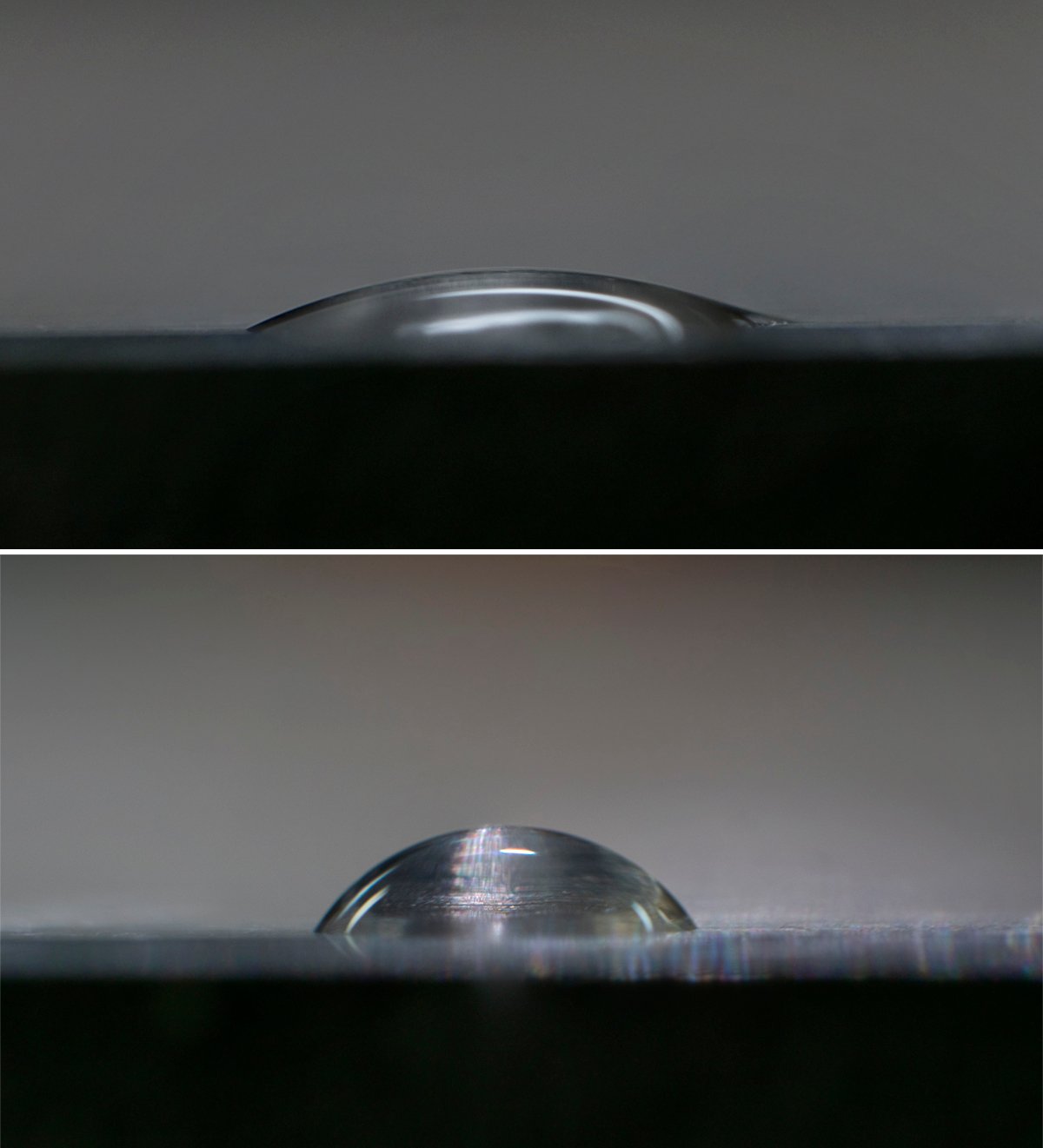

When parts arrive at your facility, they might meet print specs—but still fail in production. That’s because surface quality, especially for adhesion-critical parts, often isn’t visible and isn’t measured. Brighton Science gives you a way to define, inspect, and enforce surface performance requirements, so you can qualify the right materials and hold suppliers accountable.

Whether you’re setting specs, selecting materials, or managing supplier quality, Surface Intelligence helps you make confident, traceable decisions from the start.

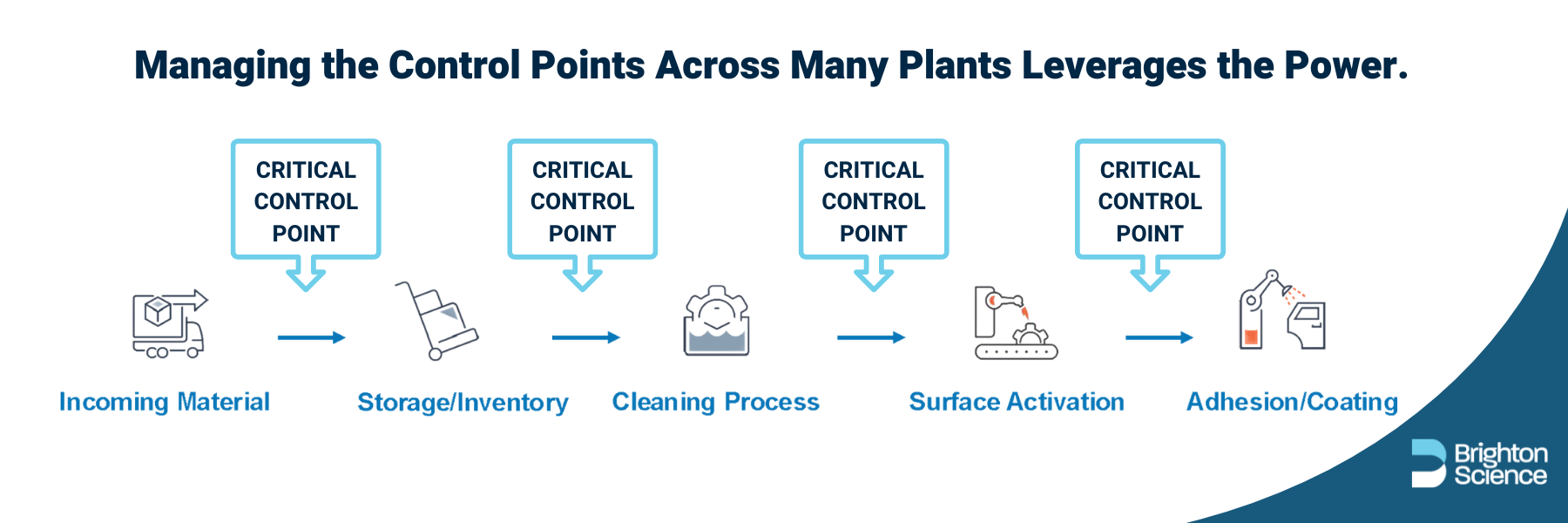

Why It Matters

When you set a surface specification, you're defining the conditions required for adhesion or coating success. But that spec only works if it can be measured—by you and your suppliers. Brighton Science helps teams validate both: the material’s surface properties and the supplier’s ability to hit target performance. We help you take control by establishing surface performance specs, qualifying suppliers, and creating inspection routines that catch problems early.

Common Uses:

- Define surface quality specs for metals, polymers, composites, and more

- Qualify new suppliers based on their ability to meet real surface criteria

- Validate supplier cleaning effectiveness

- Create inspection protocols for adhesion-critical components

- Audit variability in wafers, medical parts, or electronics

- Catch surface problems before they affect assembly

How Brighton Science Helps

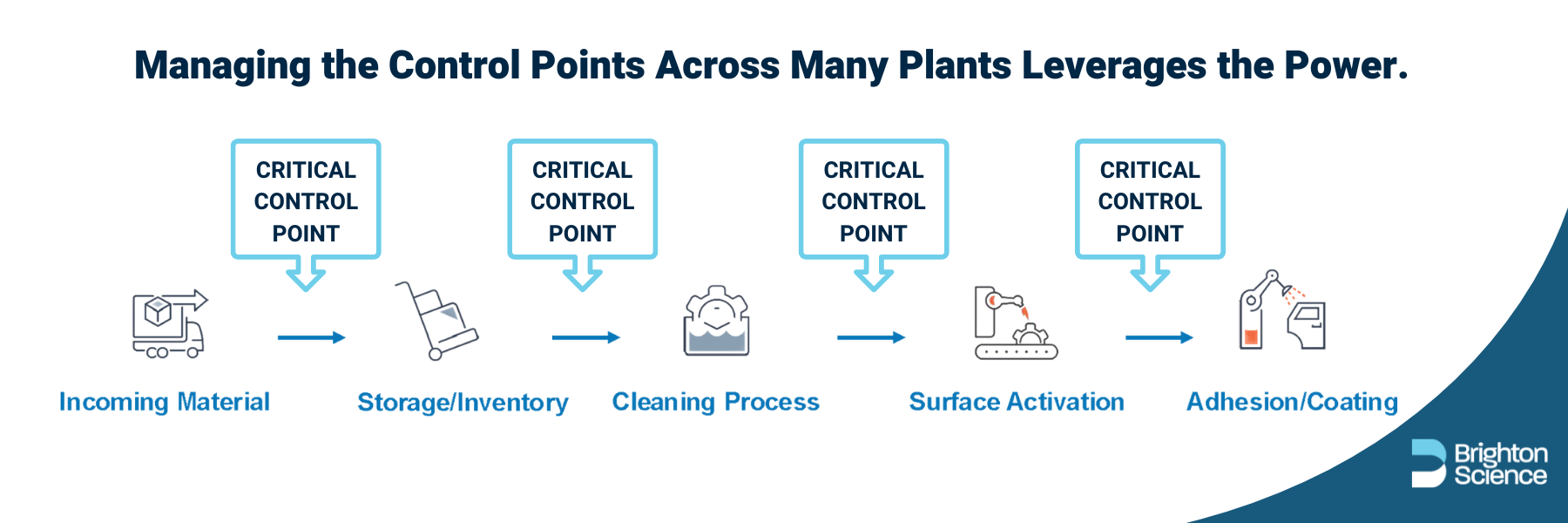

We help manufacturers and supply chain teams define and enforce surface quality standards, using real-time data to qualify materials, suppliers, and incoming parts with confidence.- Measuring surface performance before parts hit production

- Verifying adherence to cleanliness and prep standards

- Standardizing quality metrics across multiple suppliers

- Supporting supplier development and qualification

Who Benefits

Supplier performance impacts your entire operation. Brighton supports roles focused on quality, sourcing, and reliability.

Quickly investigate adhesion failures tied to supplier variability. Improve incoming inspection workflows.

Hold vendors accountable, qualify alternate sources, and use Surface Intelligence to reduce incoming variability.

Set clear surface specs during design to ensure supplier compatibility and reliability.

Our Customers

.png?width=177&height=131&name=lockhead-martin-aerospace-transparent-logo%20(177x131).png)

Unmatched educational resources to expand your knowledge and understanding

Brighton Science is the global leader in surface intelligence.