Undoubtedly, you’ve been working toward specific sustainability goals and specializing your skills to do one thing well instead of multiple things moderately well or even poorly. But if your goals align around sustainability, it’s crucial to understand who your suppliers are and how your final product will reach customers.

Your vendor sustainability practices will also affect how sustainable your products are. To ensure competency between your supply chain and your parent company, manufacturers must be critical with supply vendors when it comes to things like the adhesion quality of your product surfaces. It’s a routinely overlooked quality standards check that can occasionally sink your entire production line. When managed properly, routinely checking your products and supplies for their surface cleanliness will add actual data that backs up any assumptions that your vendors are not meeting your sustainability standards.

But this leads to the question: how can you check your supply chain distributors to guarantee the products you’re receiving meet your and your executive teams’ scrap and time-effectiveness standards?

One (nearly foolproof) way would be to add water contact angle specifications. Adding them would open up a treasure trove of opportunities to unlock high levels of potential ROI by specifying a cleanliness level that treats each individual part more quickly and more effectively.

Optimize the power of next-gen connectivity with data & surface intelligence.

Things to Watch: Quality Control Levels when Outsourcing Raw Materials

Say you’re an automotive OEM who sources components from a manufacturer specializing in producing windshields. That company focuses on one specific niche, leaving your company to outsource other factors of production, like car seats, wiring harnesses, or alternators, among other things. By letting someone who specializes in making the parts you aren’t as familiar with, you’ll increase your shareholder value tremendously.

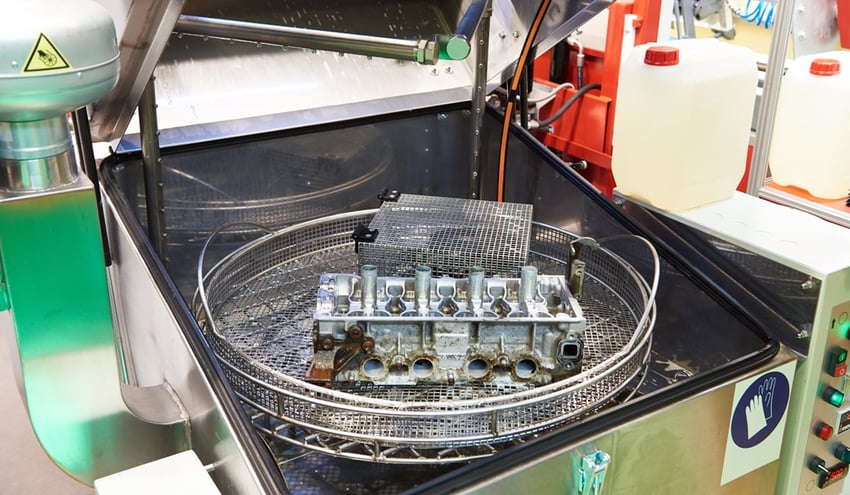

Your goals as an OEM are to ensure a high-quality production process, thorough assembly based on quantifiable data, and systemic quality management ideals to minimize delays and risks. One of the untapped ways manufacturers and OEMs can maximize output while minimizing delays and risk is to implement quality control checks on all surfaces. The easiest way to do that is using water contact angle specifications, which directly tell you, in a numerical form, how clean your surfaces are. When you have your baseline number of cleanliness needed to adhere, say, the windshield to the car’s frame, you would test each windshield given to you by your supplier, and if it doesn’t meet that cleanliness specification, you know to clean it further to meet quality standards.

And while it is cost-effective to outsource production, there are a few problems when it comes to quality control and surface cleanliness…

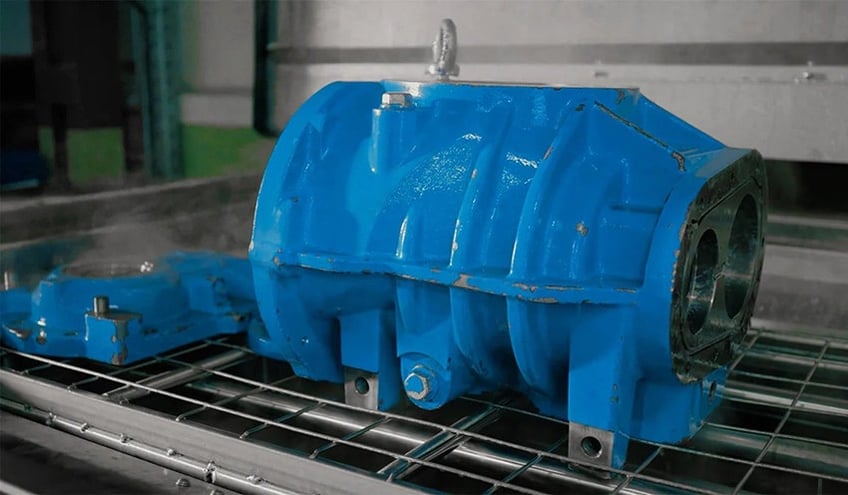

- Parts have been sitting around gathering dust (contaminant) for months

- There is no one-size-fits-all solution when it comes to adhesion

- Other supply chain companies might not share your goal of increasing bond quality

Firstly, you’ll notice that not everyone builds products or parts the same way. This is helpful because every OEM has a different use case. But when you’ve picked a supplier and ordered the parts, sometimes they’ve been sitting in a warehouse for months, waiting for you to reach the point where you’re ready to adhere the windshield to the car frame. The manufacturer now faces a dilemma. They can either utilize outdated surface energy tests, such as dyne and water break tests or opt for a more efficient method of rapid water contact angle measurements with the help of the Surface Analyst. This automated approach guarantees that the surfaces meet the required standards, saving time and effort. If you fail to measure the contact angle at this point in the process, you open yourself up to risk, which could include a variety of recalls later down the line and even injury to customers.

Secondly, there is no one-size-fits-all solution to adhesion. However, including a water contact angle specification for your supply chain suppliers and vendors reduces the risk associated with outsourcing materials. Water contact angle specifications ensure that even if your process changes, you are aware of the surface’s quality and readiness when you first receive it from your vendor. It’s one of the most effective control methods manufacturers should implement. To further minimize any potential risks, it is possible to add specifications for water contact angle during an assembly at every Critical Control Point along your production line for optimal results.

Finally, adding a water contact angle specification to your list of “to-dos” for each supplier or vendor opens up a door of accountability both for the OEM and the vendors. This is an untapped area of massive potential savings. The earlier you catch cleanliness lacking in the products you receive from outsourcing, the sooner you can clean them or ask for new ones to be made and then move on to the next step of the process. Instead of assuming the product or component from your supplier is sufficient, bonding it, and then seeing it fall apart once it’s on the road, in the air, or in the hands of an expert, you can add quality control standards and automatically reduce risk with contact angle as a surface cleanliness specification. Product failure while in the field is a bad look for the suppliers, your company, and for you.

Examples of Manufacturers that Have Specified a Cleanliness Level and Avoided Bond Failures

When we think of specific case studies, we’ve done with partners who have increased process control, and along with it, ROI, one specific automotive manufacturer comes to mind. Keep in mind implementing process control in the supply chain network applies to most (if not all) industries, not just automotive. It’s also commonly used in software, electronics, and the oil and gas industries.

The Best Duo: Water Contact Angles and the Production Parts Approval Process

The numerous automobile manufacturers Brighton Science has partnered with are routinely looking to optimize their processes and unlock potential savings by measuring cleanliness. One way our partner OEMs at automotive companies around the world test cleanliness is by measuring the water contact angle of sealing surfaces prior to receiving them at each plant (a critical control point for that process). This cleanliness measurement ensures reliability from their supply vendors and gives leadership a guidepost in case the water contact angle suddenly spikes somewhere along their process, and they’re forced to take corrective actions. Having this measurement guarantees it wasn’t the OEM’s fault, but instead, that contamination must have occurred since arriving at the plant.

This manufacturer also uses water contact angle measurements during their Production Part Approval Process (PPAP), which provides stability and consistency to the parts distributed by the supply vendors. PPAP helps reduce delays and non-conformances by providing an approval process. Manufacturers that utilize a Production Part Approval Process typically have a greater understanding of how to maintain quality control over any process changes and keep a record of all those changes. For OEMs, including a PPAP in your process alongside contact angle measurements and cleanliness standards, will streamline production, reduce warranty claims, increase supplier reliability, and increase profitability and customer satisfaction.

Rethink your adhesion manufacturing processes with Surface Intelligence.

How Brighton Science Can Enhance Process Control for All Manufacturers

It’s no surprise that implementing a tool like the Surface Analyst will unlock a new level of productivity, quality control, and cleanliness throughout your supply chain network. It’s not just imperative, but it’s necessary to add a Water Contact Angle specification to your manufacturing process to hold your suppliers accountable for defective products and to help your teams notice where you could be losing surface cleanliness in your process. Surface intelligence emphasizes techniques reflected in the teachings of Lean Manufacturing and Six Sigma, specifically the following:

- Employing quality control in all aspects of your production process

- Delivering consistent and high-quality products

- Utilizing Root Cause Analysis and data-based specifications (water contact angle) to control your surfaces and, therefore, your finished products

Discover some of the new ways sustainability practices can ensure productivity and quality meet your standards by checking out our eBook, "Metrics that Matter: Quantifying Cleaning Efficacy for Manufacturing Performance."