Formed-in-place gaskets (FIPG) have revolutionized sealing solutions across industries that require high-reliability seals. While there are many types of gaskets, a FIPG is created from a specific method where a liquid sealant, typically applied by an automated dispensing system, is dispensed directly onto a surface to fill the designated area precisely, forming a reliable seal between two components. Once applied, the liquid adhesive undergoes a curing process—activated by heat, light, or moisture—which solidifies the gasket exactly where needed, creating a custom-fit, durable seal. FIPG's adaptability to various material surfaces, especially in industrial applications, has made it indispensable in industries like automotive and electronics, where precision sealing is crucial.

However, the reliability of these gaskets isn't just about the materials used or the application process—it starts with the quality and preparation of the surface itself.

This article explores why surface quality is a fundamental factor in FIPG reliability and offers insights into how advanced surface analysis can help manufacturers improve outcomes, reduce waste, and uphold quality standards.

Understanding FIPGs

Because of the versatility and reliability of FIPGs, they are invaluable to industries requiring high-performance sealing solutions. Common applications include:

- Automotive: Used to seal engine blocks, transmission housings, and battery packs for EV vehicles, as well as electronics to withstand variable temperature ranges, vibration, and moisture.

- Electronics: Seals battery enclosures, wearables, and LEDs for moisture and dust protection.

- Aerospace: Essential for avionics, fuel systems, and cabin pressurization.

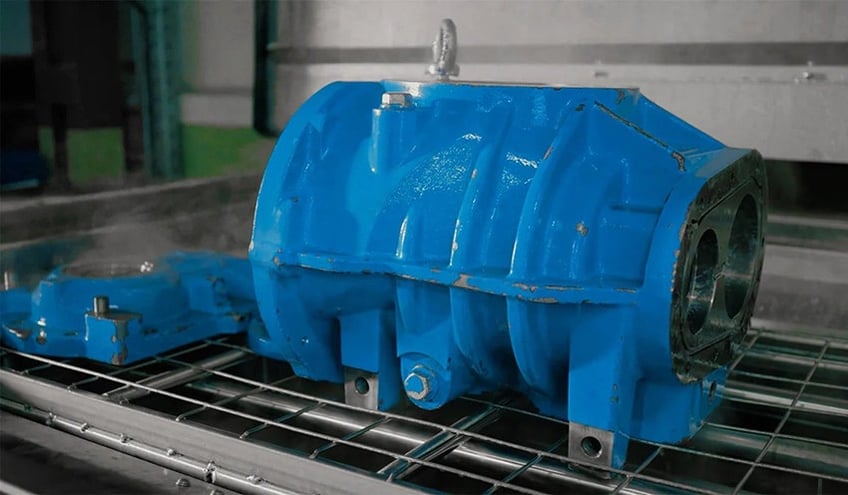

- Industrial Equipment: Seals pumps, compressors, and pipes, shielding from chemicals and high pressures.

- Medical Devices: Creates sterile barriers in diagnostic and portable devices.

- Telecommunications: Protects outdoor enclosures and fiber optics from environmental exposure.

- Appliances: Ensures watertight seals in washers, dryers, HVAC, and kitchen appliances.

- Renewable Energy: Seals solar panels, wind turbines, and battery storage against environmental damage.

Advantages of FIPGs

Unlike traditional gasket materials, FIPGs offer precision, filling complex shapes and tight spaces with accuracy, which traditional gaskets cannot match. Their durability allows them to resist extreme temperatures, corrosion, UV exposure, and mechanical stresses, making them ideal for demanding environments.

FIPGs are versatile, fitting both small and large applications. They are also highly efficient, reducing waste by using only the exact amount of material needed. By curing directly on the component, they simplify assembly, reduce production steps, and are more cost-effective, making them a top choice for manufacturers focused on reliability and cost-efficiency.

It’s fast. It’s accurate. It’s non-destructive. It’s the Automated Surface Analyst.

The Importance of Surface Quality for FIPG Effectiveness

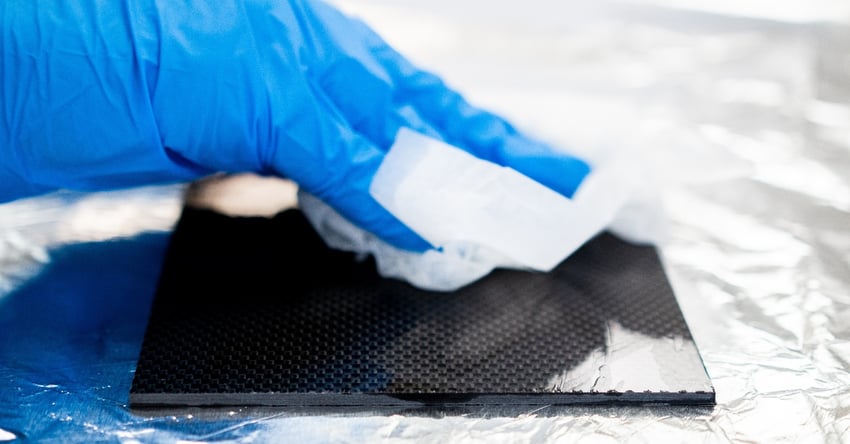

While FIPGs offer many advantages, they demand a fresh approach to assembly that prioritizes surface cleanliness and a molecular-level understanding of adhesion to ensure reliable sealing. A strong bond ensures that the gasket can maintain its seal under pressure, vibration, and temperature changes. The success of this adhesion is contingent on surface quality. Without rigorous surface preparation and data to ensure the quality of the material surface is to-spec, adhesion becomes unreliable, jeopardizing the seal's integrity and the product's longevity.

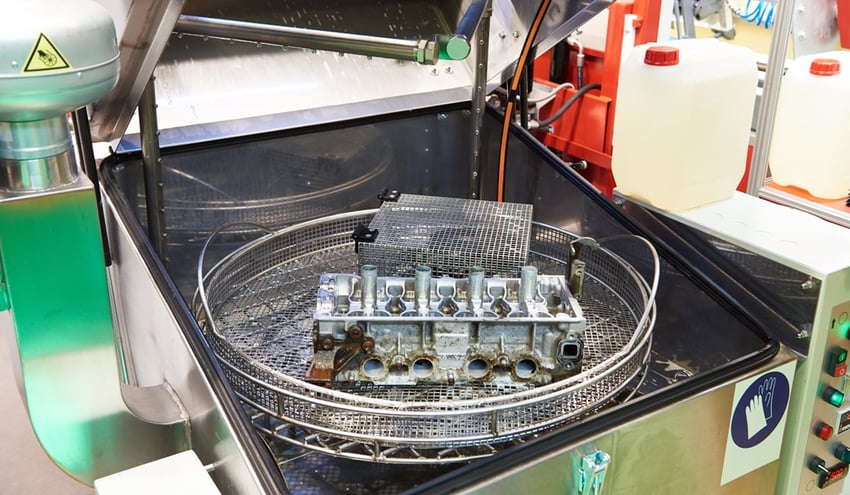

To ensure high-quality surfaces, it's essential to identify sources of contamination, thoroughly remove them, optimize surface conditions, establish a clear surface quality specification, and continuously monitor the process to prevent any decline in surface quality.

The Science Behind Surface Quality and FIPG Reliability

Adhesive bonding appears in many forms in manufacturing, but the principles of adhesion science remain consistent. This multidisciplinary field studies how interfaces form, behave, and adhere where two different materials meet, focusing on the adhesion forces and molecular interactions that enable these bonds and influence their durability over time.

Whether bonding metal joints with adhesives, sealing components with industrial gaskets, coating medical devices, printing on polymers, or painting vehicles, strong adhesion depends on three critical factors:

- The composition of the adhesive, coating, ink, or paint

- The application of the adhesive, coating, ink, or paint

- The quality of the bond surface

While there are established methods for controlling adhesive formulations and application techniques (steps 1 and 2), ensuring surface quality poses a unique and complex challenge (step 3). The bond surface is highly susceptible to changes and affected by numerous variables, making it the most challenging aspect to control for reliable adhesion.

Critical Control Points for FIPG Success

Surface Preparation and Quality Control

To enhance surface quality, manufacturers often apply pre-treatments such as plasma, flame, or corona, which alter the material at a molecular level to improve its readiness for bonding. However, verifying the effectiveness of these treatments before gasket application is essential to avoid adhesion failures.

With Brighton Science's Surface Analyst technology, quality teams can precisely assess whether treated surfaces have the required adhesion characteristics, ensuring consistency and reliability. This validation step helps reduce rework and scrap costs by catching potential bonding issues early in the process, ultimately supporting higher-quality outcomes in production.

In-Process Surface Monitoring

Variability between production sites or shifts can lead to inconsistencies that affect gasket performance. To ensure reliable adhesion, monitoring critical control points (CCPs) throughout the process is essential for maintaining surface quality. Real-time data collected at these CCPs, using platforms like Brighton Science's BConnect, provides visibility across multiple manufacturing locations. This continuous monitoring enables teams to detect and address any surface deviations instantly, supporting consistent quality and reducing the risk of bonding issues.

Maintaining Ideal Surface Quality During Production

Surface quality can deteriorate throughout production due to factors like packaging, handling, environmental exposure, and equipment use. Monitoring surface conditions is essential to sustain optimal performance for formed-in-place gaskets.

By adopting a systematic approach to surface quality assurance, manufacturers can ensure consistent reliability across production runs and uphold high product standards, preventing adhesion issues before they occur.

Leveraging Surface Analysis for Gasket Reliability

Utilizing surface analysis tools like BConnect allows manufacturers to implement predictive quality control, enabling them to monitor surface quality in real time and prevent gasket adhesion issues before they arise. With data analytics capabilities, production teams can make proactive adjustments, reducing costly quality concerns after production is complete.

As Industry 4.0 technology transforms manufacturing, integrating surface quality monitoring into automated, digital production systems opens up new possibilities for connectivity and accuracy. Systems like BConnect, with cloud-based data sharing, allow seamless collaboration across departments, streamlining processes, reducing human error, and driving consistent quality control for formed-in-place gasket applications.

Elevating FIPG Reliability Through Advanced Surface Control

As the demand for robust, leak-proof sealing solutions continues to grow across industries—from automotive to electronics—ensuring the reliability of formed-in-place gaskets becomes increasingly critical. Surface quality, monitored and maintained with precision, is at the heart of successful FIPG application. By leveraging advanced surface analysis and Industry 4.0-enabled solutions, manufacturers can minimize failure rates, reduce waste, and achieve higher levels of customer satisfaction, all while maintaining operational efficiency.

To learn more about improving adhesion by controlling your cleaning processes, download the eBook "Metrics That Matter: Quantifying Cleaning Efficacy for Manufacturing Performance."