Applications

Surface Preparation & Activation

When Prep Isn't Right, Nothing Sticks

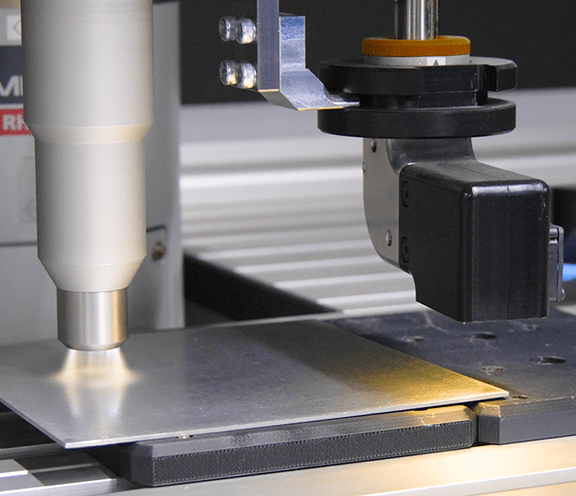

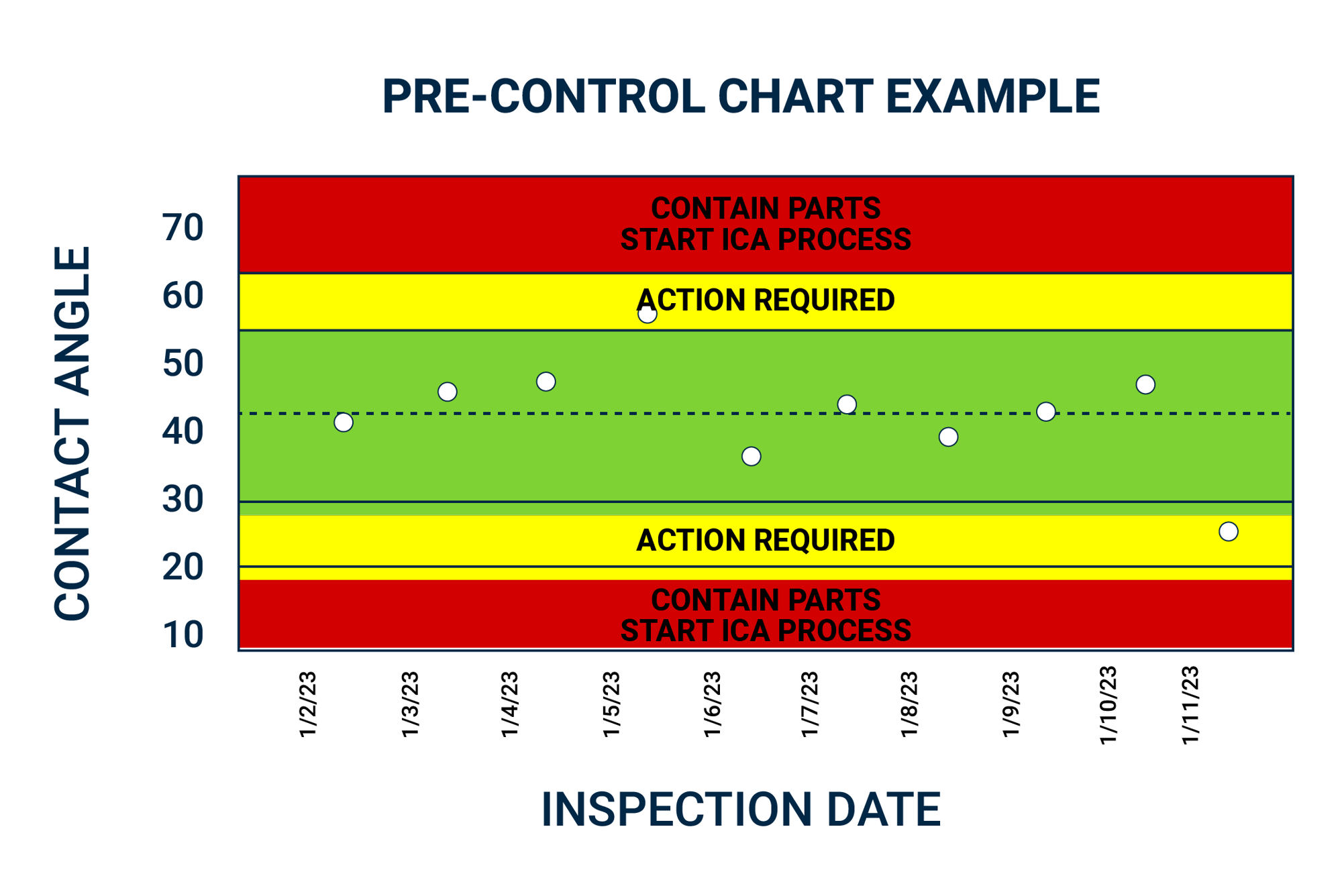

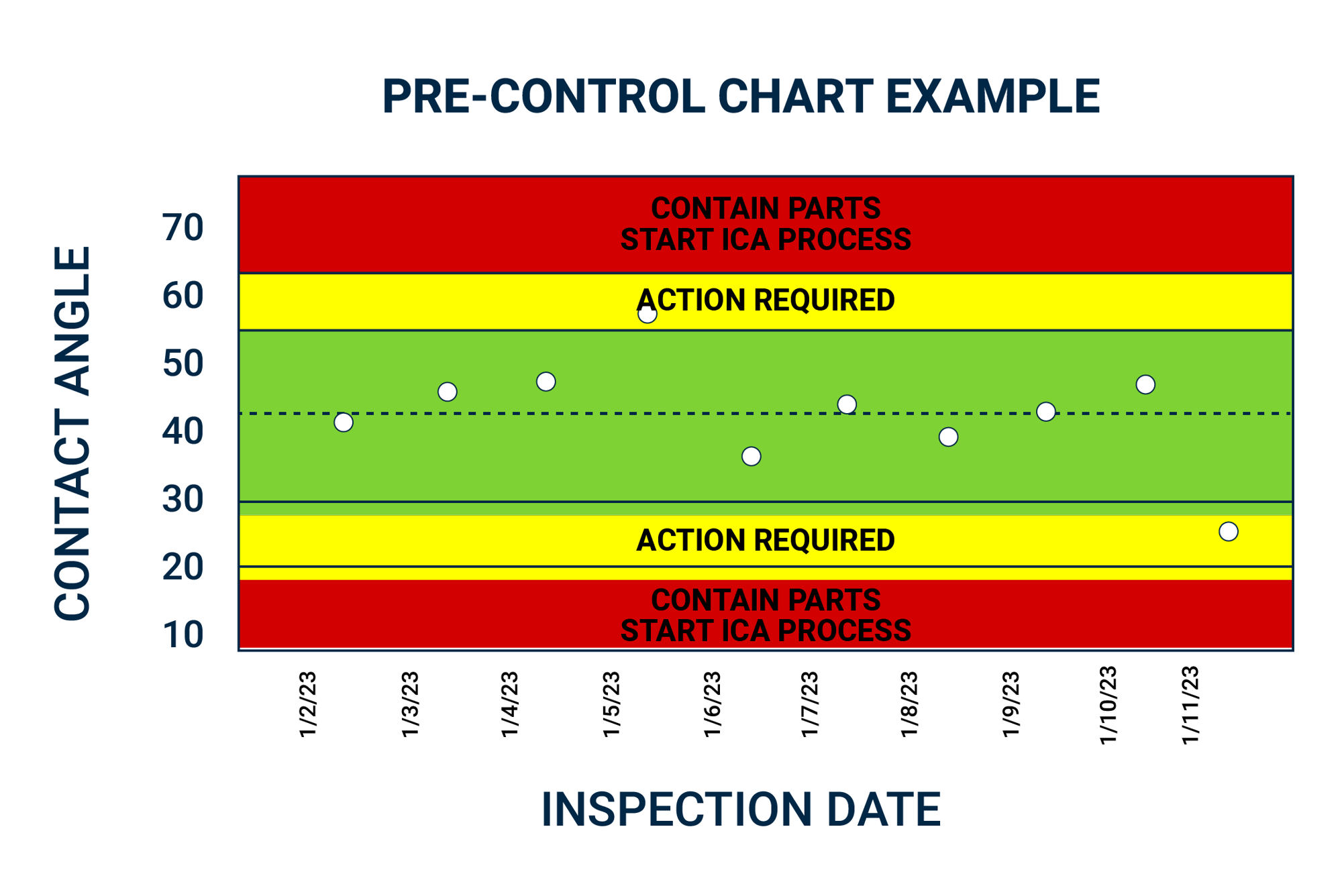

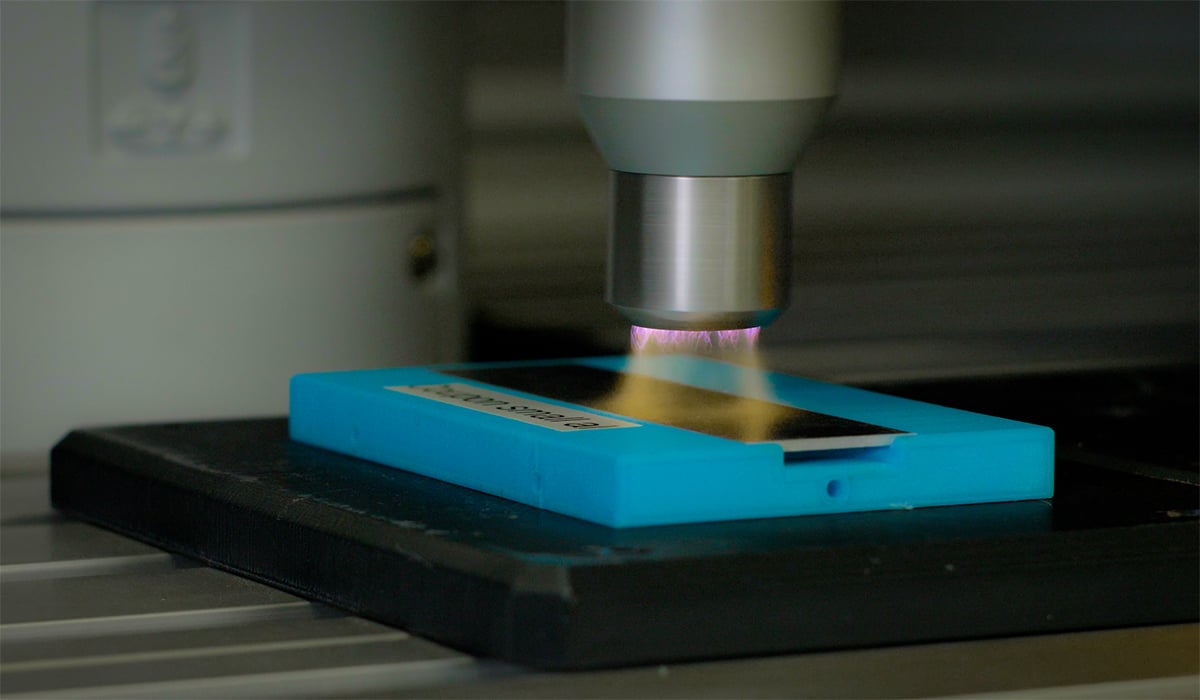

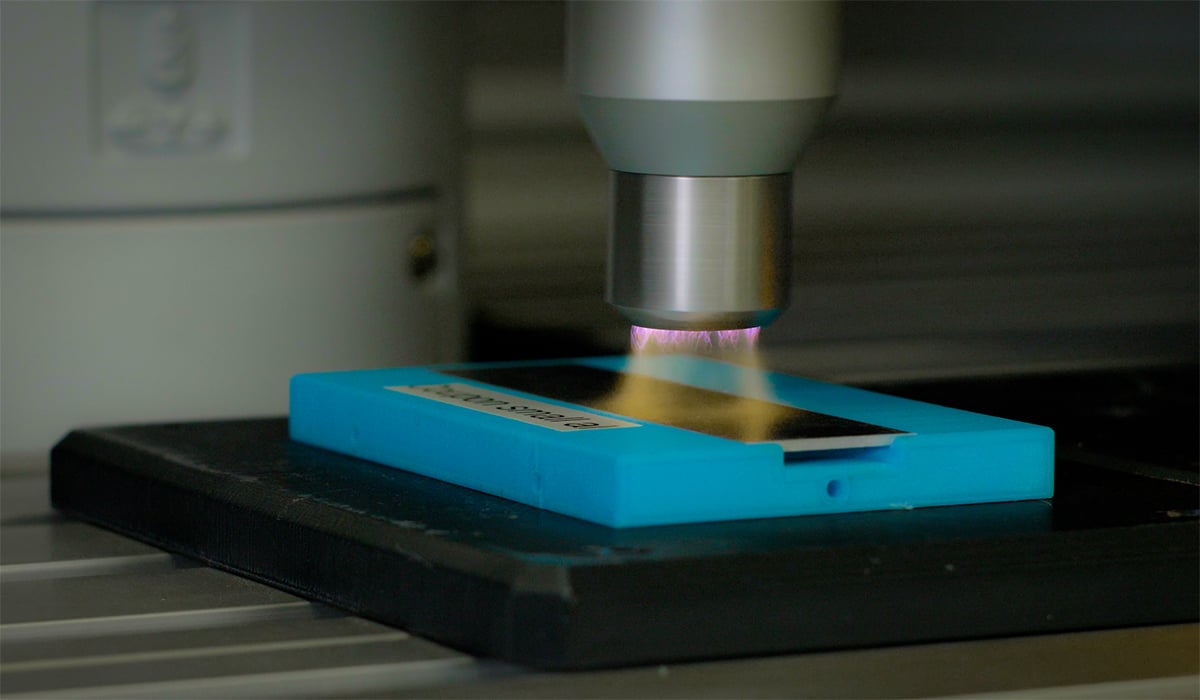

Surface preparation is a critical—but highly variable—part of the adhesion process. From flame and plasma treatment to abrasion and cleaning, surface prep relies on consumables, equipment settings, and human execution.

Brighton Science helps manufacturers measure and control this variability, ensuring that prep is performed consistently and adhesion outcomes are reliable.

Why It Matters

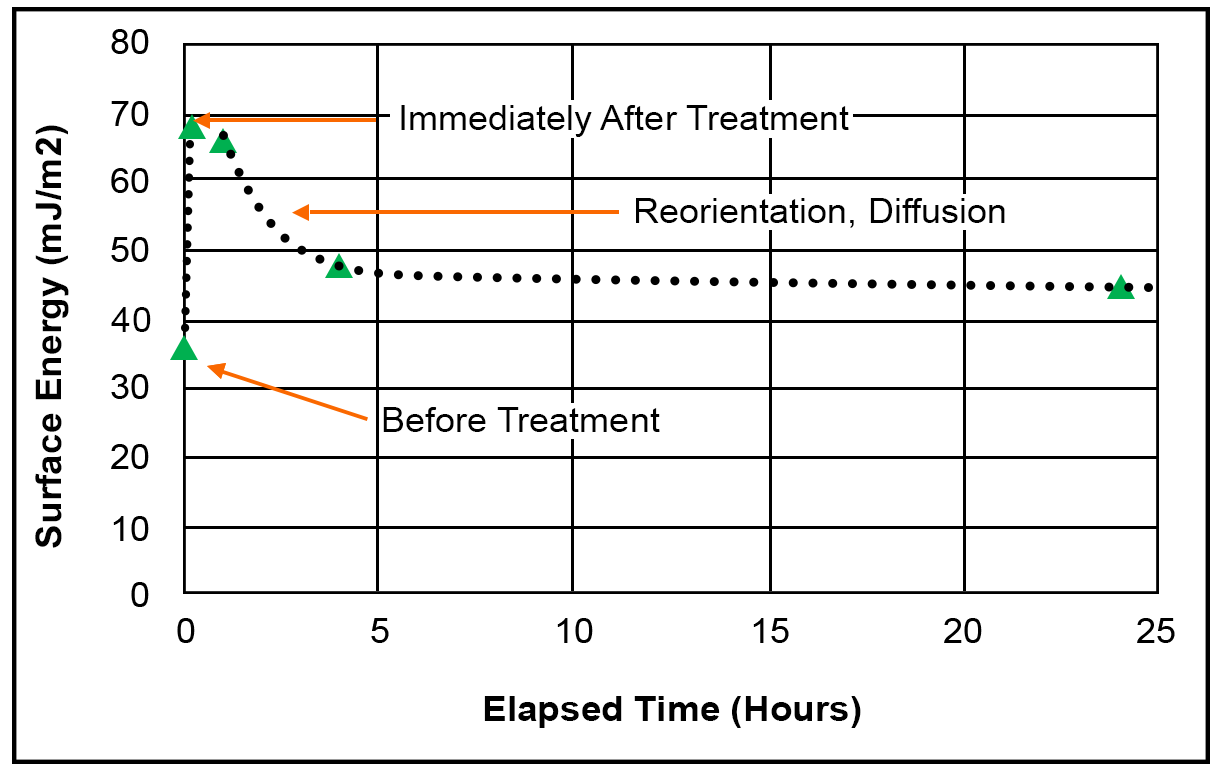

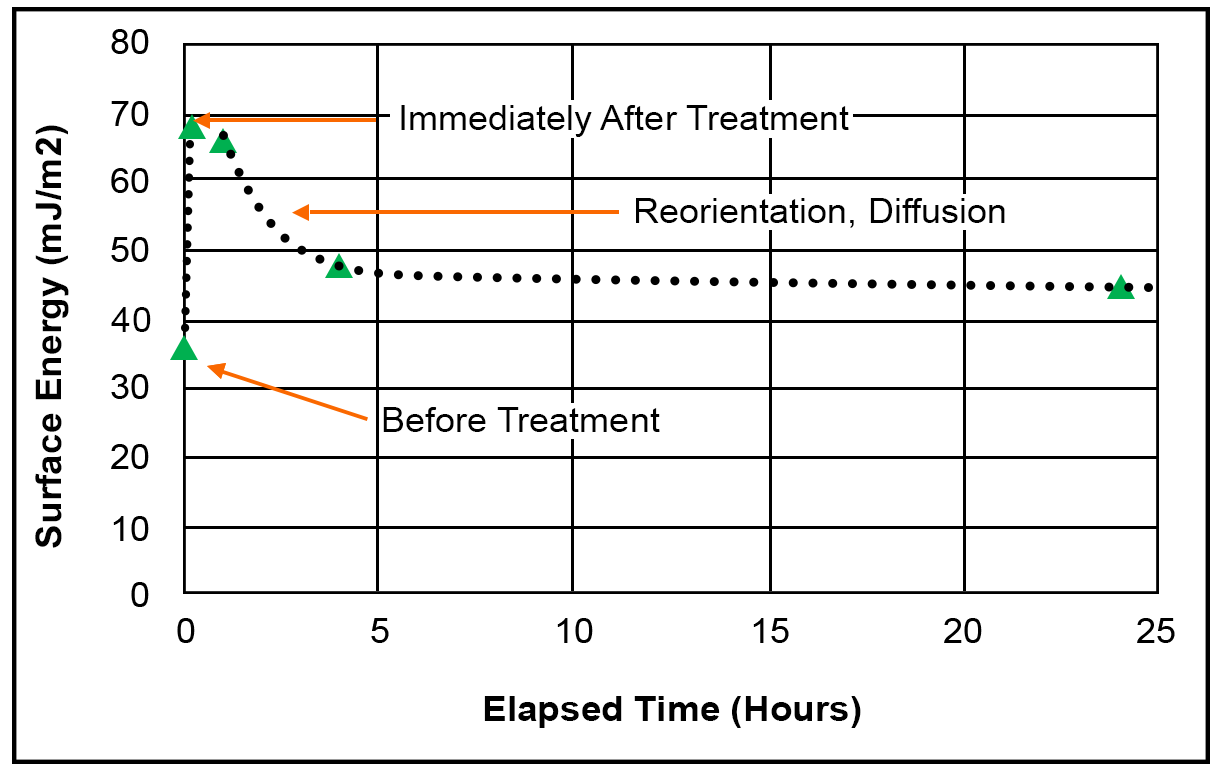

Surface preparation isn't just about removing contaminants—it's about conditioning the surface so it can form strong, stable bonds. Cleaning may be part of prep, but it doesn’t guarantee the surface is chemically ready. That's why manufacturers must go further—measuring the effects of their treatments and linking them directly to adhesion performance.

Brighton Science helps you fine-tune preparation and activation techniques and link those directly to adhesion outcomes. From development through production, we give you the data to build repeatable, high-performing processes that get it right the first time.

Common Uses:

- Optimize plasma or flame treatment parameters

- Validate surface prep across a range of components and materials, from catheters to composites

- Detect under- or over-treatment before bonding

- Validate adhesion strength pre-production

- Troubleshoot bonding failures by linking them to prep variability

How Brighton Science Helps

We help manufacturers control the variability in surface preparation by connecting treatment methods—like plasma, flame, or abrasion—with measurable, repeatable indicators of bonding readiness:- Manage variability in surface prep caused by equipment settings or operator actions

- Verify surface status after grit blasting, plasma, or flame treatment

- Standardize prep processes across global sites or supplier locations

- Detect and correct under- or over-treatment before bonding

Who Benefits

Surface prep and adhesion success involve multiple teams—Brighton Science equips each with tools and insights that deliver results.

Fine-tune surface treatment steps and validate them with real data to reduce failure modes and improve first-pass yield.

Ensure prep consistency, reduce scrap and rework, and keep production lines running with fewer surprises.

Qualify materials and processes with real-world bonding outcomes, not assumptions. Build flexibility into your design toolbox.

Our Customers

.png?width=177&height=131&name=lockhead-martin-aerospace-transparent-logo%20(177x131).png)

Unmatched educational resources to expand your knowledge and understanding

Brighton Science is the global leader in surface intelligence.