Key Takeaways

- Effective surface treatment is essential for strong, predictable adhesion in bonding, coating, printing, and sealing processes.

- Each treatment method has distinct advantages, limitations, and material compatibility considerations.

- Monitoring chemical surface condition is as important as performing the treatment itself.

- Surface Intelligence tools help teams verify treatment performance, reduce variation, and prevent adhesion failures.

Manufacturers invest heavily in bonding, coating, painting, and printing processes. Yet many adhesion challenges can be traced back to one area that often gets overlooked at the molecular level: surface condition. Surface treatment is how teams prepare surfaces so adhesives, coatings, inks, and other materials can form strong chemical bonds.

This guide walks through the most common surface treatment methods used in modern manufacturing and explains where each one excels.

What Surface Treatment Really Does

Surface treatment changes the chemical characteristics of only the top few molecular layers of a substrate. Those layers determine how well the material will react with an adhesive, a coating, a paint, or another surface.

Adhesion is a chemical interaction between two surfaces. When the surface is chemically unprepared, even the best adhesive or coating cannot compensate. When the surface is activated and chemically aligned, adhesion becomes predictable and repeatable.

That is why a controlled treatment process and regular surface quality checks are essential.

Common Surface Treatment Methods

Below is a practical overview of widely used surface treatment categories and where they are most effective.

Plasma, Flame, and Corona Treatments

These treatments modify the surface through chemical activation. All three methods introduce energetic species that break molecular bonds and create a more reactive surface.

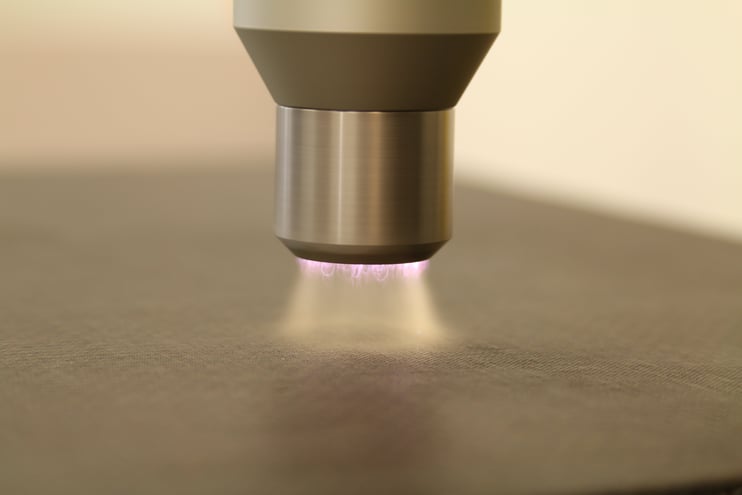

Plasma Treatment

Available in two formats, each suited for different applications:

Atmospheric Plasma

- Uses ambient air through a nozzle.

- Ideal for small areas or continuous inline processes.

- Common in high-throughput manufacturing where integration into existing lines is important.

Vacuum Plasma

- Conducted in a sealed chamber with controlled gas mixtures.

- Enables high precision for coatings and specialized applications.

- Used when exact gas chemistry is required, such as optical coatings on eyeglasses.

Corona Treatment

- Uses high-voltage electrical discharge across the surface of a polymer film.

- Well suited for printing, laminating, and coating applications in film manufacturing.

- Considered the least thermally aggressive of the three treatments.

Flame Treatment

- Uses a controlled blend of natural gas and air to create a hot, oxygen-rich plasma.

- Effective on low-surface-energy materials like plastics and composites.

- Can cause melting or formation of low-molecular-weight oxidized material if not optimized.

Key Considerations

- Under-treating or over-treating can both harm adhesion performance.

- These processes do not remove heavy oils or large particulates.

- Ongoing calibration is essential because treatment strength can drift over time.

- A surface quality measurement tool, such as the Surface Analyst, is valuable for validating treatment effectiveness.

Chemical Etching

Chemical etching uses temperature-controlled chemical baths to remove contamination and activate metal surfaces.

Common uses:

- Microelectronics

- Medical devices

- Precision metal components

Risks:

- Process drift leading to chemical contamination

- Variation in etch uniformity if not tightly controlled

Vapor Degreasing

This method cleans by exposing parts to rising solvent vapor from a heated bath. The vapor condenses on the part, dissolves contaminants, and carries them away.

Advantages:

- Efficient removal of oils and light soils

- Solvent recovery can reduce operating cost

Requirements:

- Solvent must be compatible with the material

- Recovered solvent must be distilled and verified to be contaminant-free

- Thorough rinsing is necessary before bonding or coating

Laser Ablation

Laser ablation removes very small amounts of material with a focused or pulsed laser beam.

Applications:

- Micro cleaning and precision surface activation

- Creation of thin films or nanostructures

- Drilling of micro features

Risks:

- Formation of micro debris if not monitored

- Excessive treatment can convert the surface material into plasma and damage the part

Why Surface Treatment Alone Is Not Enough

Surface treatments play a critical role in preparing materials for bonding, coating, printing, or sealing. Yet even the most advanced or precisely tuned treatment will not deliver consistent results without strong process controls surrounding it. A surface can be perfectly activated at one stage, then rendered unbondable only minutes later if the environment or workflow introduces new variables.

In real production environments, several dynamics can erode surface quality after treatment:

- Parts may travel through multiple departments or handling steps where skin oils, dust, or airborne contaminants can be reintroduced.

- Equipment parameters such as gas ratios, power levels, temperature, or standoff distance may drift over time, reducing treatment intensity without operators noticing.

- Environmental factors like humidity, airborne oils, cleaning agents, or off-gassing materials can chemically alter a surface that was previously well prepared.

- Delays between treatment and assembly can allow the surface to de-activate or revert to a lower-energy state.

Because so many variables sit outside the treatment step itself, relying solely on the treatment method creates blind spots. Teams need a reliable way to verify the chemical surface condition at the moment of assembly. This ensures that the surface is still in a bondable state and that upstream processes have not unintentionally undermined the initial treatment.

When manufacturers incorporate surface measurement tools into their workflow, they gain the ability to:

- Validate that treatment settings are producing the desired chemical outcome.

- Detect contamination or variability immediately, rather than discovering adhesion failures later.

- Standardize expectations across shifts, suppliers, and equipment.

- Confidently move from reactive troubleshooting to proactive control.

Surface treatment sets the stage. Verification ensures the performance you expect is actually happening. Together, they form the foundation of a predictable, high-quality adhesion process.

Designing Adhesion Processes with Surface Intelligence

Adhesion failures range from subtle quality issues to critical safety risks. Many organizations struggle with root cause analysis because the chemical surface state is rarely measured directly.

Surface Intelligence provides a data-driven framework that allows teams to:

- Measure surface quality at the molecular level

- Calibrate surface treatment systems with confidence

- Detect upstream and downstream contamination events

- Standardize workflows across operators, shifts, and suppliers

- Build repeatable, predictable manufacturing processes

When teams can see what is happening on the surface, they can prevent adhesion failures rather than react to them.

Surface treatment is only one part of building predictable adhesion. Use the Surface Intelligence Maturity Model to evaluate your current capabilities and identify practical improvements that move your team toward higher consistency and performance.

Frequently Asked Questions

Q: What is the main purpose of surface treatment in manufacturing?

Surface treatment prepares the top molecular layers of a material so adhesives, coatings, inks, or paints can form strong chemical bonds. Without proper surface preparation, even high-performance adhesives or coatings struggle to deliver consistent results.

Q: How do I know which surface treatment method is right for my material?

The best method depends on the material type, how reactive it is, the size of the treatment area, and the performance expectations of the assembly. Plastics and composites often respond well to plasma, flame, or corona treatment, while metals may require chemical etching, vapor degreasing, or laser ablation.

Q: Why do adhesion issues still occur even after treatment?

Surface treatments improve bondability, but the surface can be contaminated or deactivated later in the process. Handling, environmental factors, equipment drift, or delayed assembly can all reduce surface readiness. Verification ensures the surface is still in the correct chemical state at the moment of bonding or coating.

Q: Does surface treatment remove all contaminants?

No. Some treatments modify surface chemistry but do not remove heavy oils, particles, or residues. Identifying contamination sources and confirming that surfaces are both clean and activated is essential.

Q: How can manufacturers verify that a surface is ready for adhesion?

Chemical surface quality can be measured directly using tools that quantify the surface’s ability to form molecular bonds. This helps teams validate treatment performance, catch unexpected contamination, and maintain process control.

Q:What is Surface Intelligence and why does it matter?

Surface Intelligence is a data-driven approach that measures and monitors surface quality throughout production. It gives teams real visibility into the chemical condition of surfaces so they can adjust processes, reduce variation, and prevent adhesion failures before they reach customers.