Applications

Surface Stability & Environmental Exposure

Surfaces Change - Even When Prep is Perfect

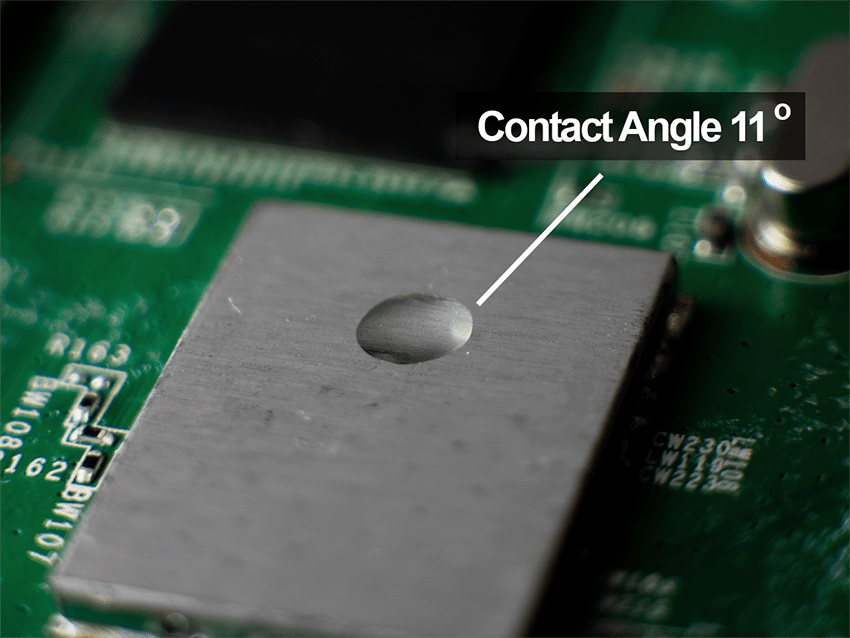

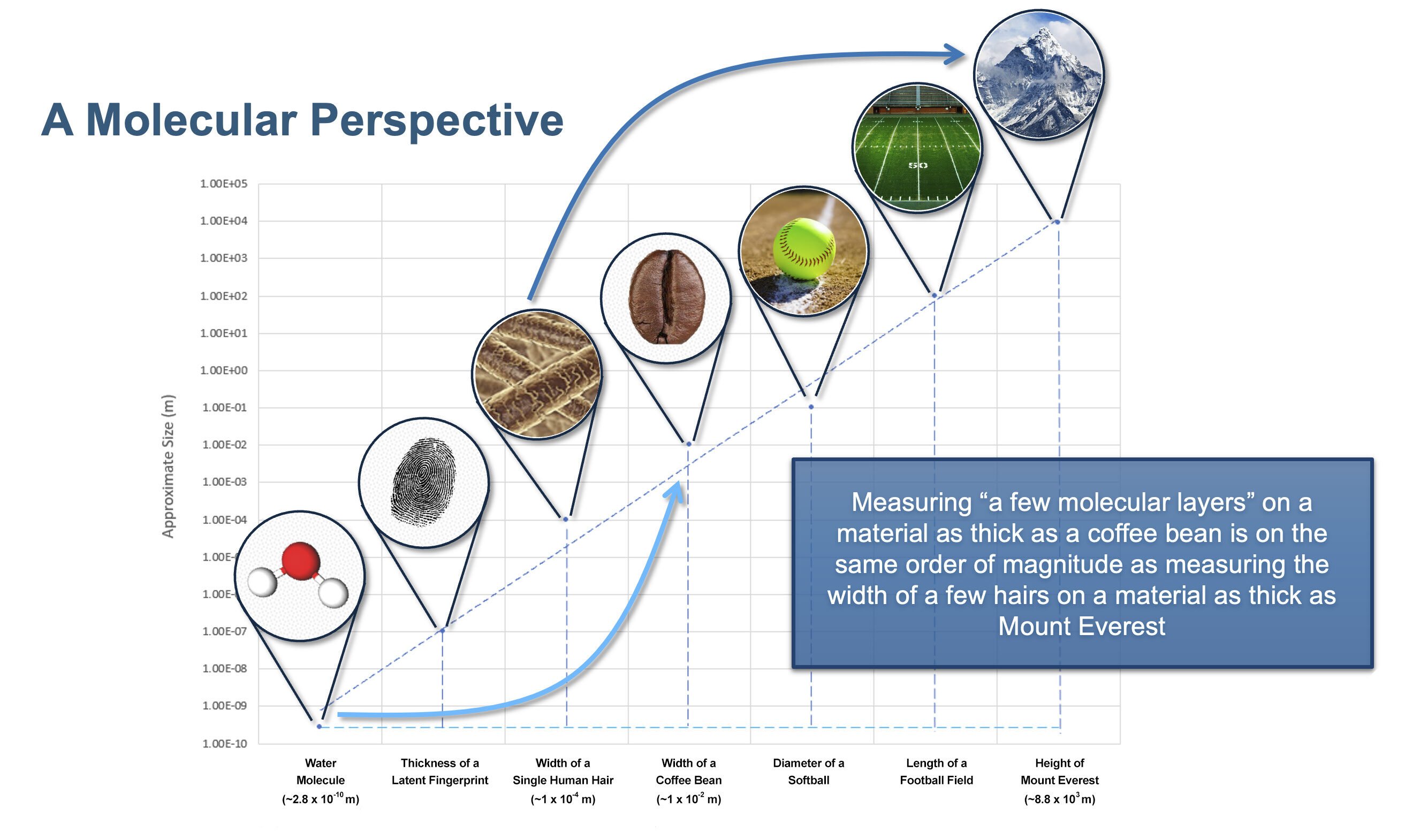

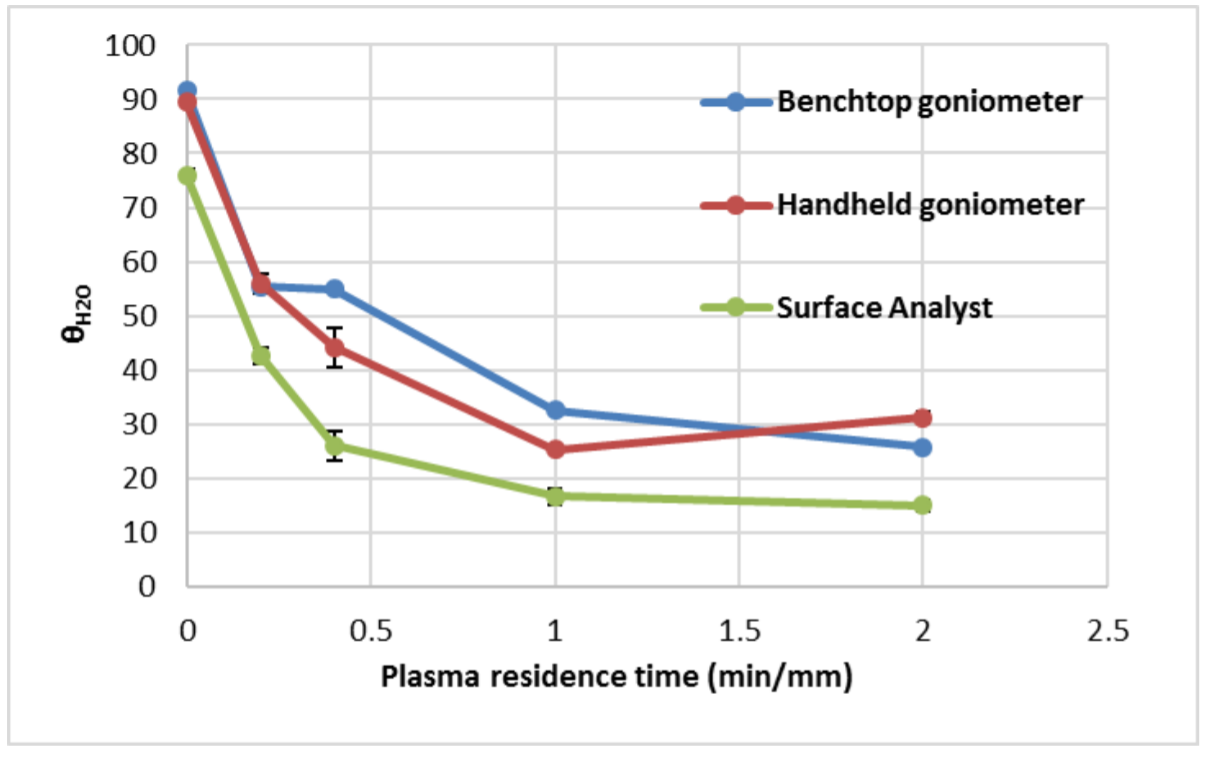

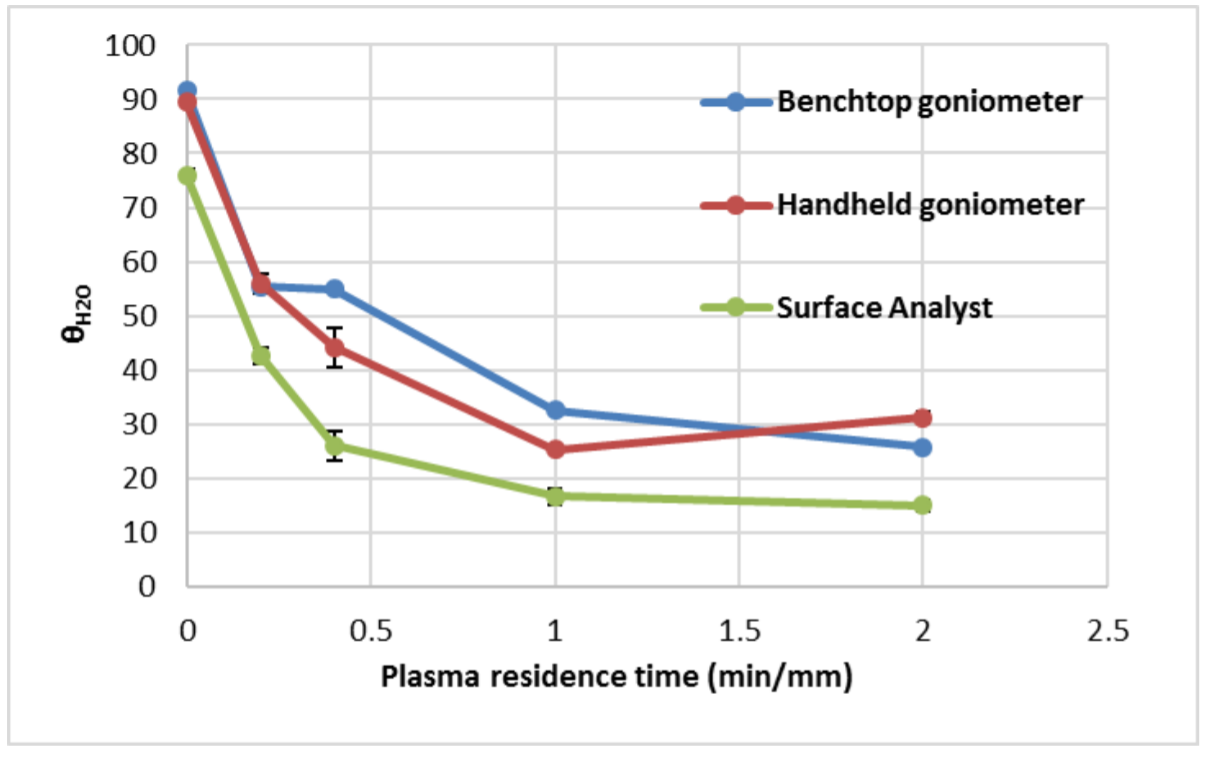

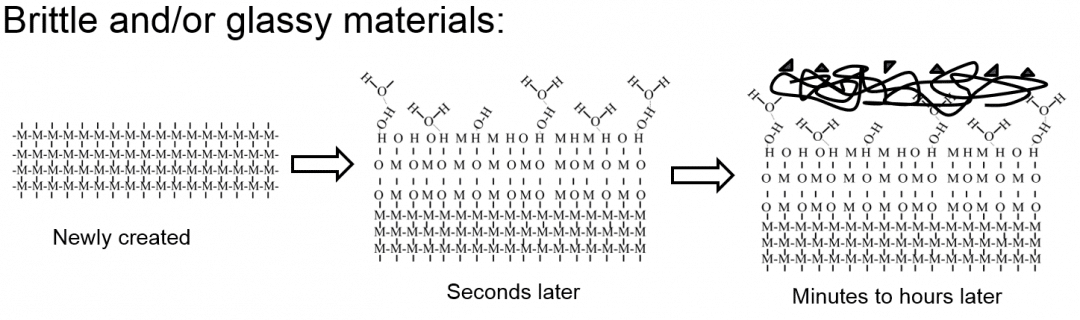

Surface quality isn't static. Once a part is prepped, its condition immediately begins to change—affected by time, temperature, humidity, and handling. These shifts often go unnoticed, but they can reduce surface energy, degrade adhesion reliability, and introduce latent risks into your production process.

Brighton Science helps you detect and understand these changes, so you can control storage protocols, timing windows, and environmental impact across your workflow.

Why It Matters

A surface that’s prepped on Friday may no longer be bond-ready by Monday. Without visibility into how time and environment degrade surface quality, manufacturers unknowingly introduce risk.

Brighton’s solutions give you visibility into these shifts—so you can determine acceptable time windows, storage conditions, and handling methods with confidence, and avoid surprises in production or the field. Our tools help ensure surfaces are still fit for purpose—days, weeks, or months later.

Common Uses:

- Validate surface readiness after storage or shelf life

- Assess aging or oxidation impacts on surface quality

- Define hold times between surface prep and bonding

- Factor environmental conditions into process controls

- Set material handling standards based on surface decay rates

How Brighton Science Helps

We help manufacturers detect, quantify, and control the time- and environment-driven changes that silently degrade surface performance.- Measure the effects of time and environment on critical surfaces

- Set hold-time windows or re-cleaning requirements

- Predict how changes in surface condition will impact adhesion

- Conduct data-driven failure analysis for warranty and recall cases

Who Benefits

Lifecycle effects span development, operations, and post-production. Brighton Science gives each group the tools to understand, predict, and control surface performance over time.

Track how prep quality degrades with time or exposure, and set meaningful time-based specs.

Prevent issues from long delays between prep and bonding. Reduce risk of latent failures in the field.

Design for durability by understanding how surface changes affect product life under real conditions.

Our Customers

.png?width=177&height=131&name=lockhead-martin-aerospace-transparent-logo%20(177x131).png)

Unmatched educational resources to expand your knowledge and understanding

Brighton Science is the global leader in surface intelligence.