Does your business, or your customer’s business, deal with adhesion – either in the form of bonding, coating, sealing, printing, or painting? Given that these processes may be occurring either upstream or downstream, does everyone in your organization share a common understanding and appreciation of “best practices” for material handling with an eye towards keeping surfaces chemically clean?

At Brighton Science, we are committed to helping customers discover the root cause of adhesion failure and design new products and processes to avoid adhesion failure. With the help of Brighton Science's expert scientists and Surface Analyst™ technology, many customers have Eureka Moments when they understand that the material handling process at their organization has encountered a glitch — including when a seemingly unsubstantial purchasing decision can inadvertently introduce chemical contamination into critical surfaces that are being prepared for bonding.

Read below to learn more about how to maintain chemically clean surfaces for the entirety of your manufacturing process — including real-world examples regarding some of our customers’ own Eureka Moments.

Understanding the Cleanliness of the Top Few Molecular Layers

Applications such as bonding, coating, printing, painting, or sealing all require adhesion of the top few molecular layers of the surface. It is not enough to merely “clean” a surface; maintaining that cleanliness through every step of the production process is imperative to achieving successful, reliable, and repeatable adhesion.

To understand the vulnerability that these top few molecular layers have to surface contamination, let’s review what happens to a chemically clean surface over time.

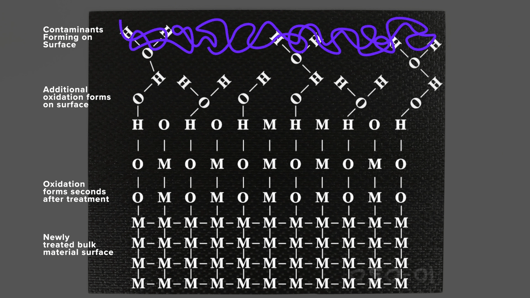

The bottom of this image shows the surface of a metal (M) that is chemically clean.

Let’s consider that surface to be chemically “pristine.” When this pristine surface is exposed to the environment, it will very quickly become oxidized. Once oxidation occurs, the surface attracts airborne water molecules. Shortly after, water molecules become attached to the surface, and the surface then attracts additional organic polar contaminants and then non-polar organic contaminants. At this point, the surface is no longer chemically clean, and adhesion efforts are likely to fail because you are no longer bonding the coating, print, paint, or adhesive to the bulk material of the metal surface. Instead, you are bonding to the layers of contamination that lay on top of the bulk material.

It is important to understand that this contamination process occurs very rapidly — the contamination process can actually begin just a few moments after the surface has been either chemically (i.e., solvent wiped, chemically etched, etc.) or mechanically (i.e., grit blasted, sanded, etc.) cleaned.

Rethink your adhesion manufacturing processes with Surface Intelligence.

Review Manufacturing Processes to Eliminate Chemical Contamination of Surfaces

Given the extraordinary vulnerability of the top few molecular layers of a surface to chemical contamination, it is important to take a holistic view of your entire production process to fully understand each step that can leave a surface at risk for chemical contamination.

A Critical Control Point (CCP) is any step in your manufacturing process where the surface condition of a material has the opportunity to change — intentionally or unintentionally — and impact adhesion in a positive or negative way. Obtaining an understanding of your particular CCPs requires that you develop a comprehensive understanding of how materials flow through each stage of your manufacturing process, including:

- The surface quality of incoming materials from suppliers

- Ambient warehousing conditions

- Surface Preparation

- Parts washer, solvent wiping, ultrasonic cleaning

- Corona, plasma, flame, abrasion

- Cleaning processes

- Surface activation

- The chemical state of a surface just before adhesion

- Printing, coating, soldering, priming, painting, bonding, welding

Secondary Sources of Surface Contamination

It’s important for manufacturers to understand that contamination isn’t always obvious, and secondary sources of contamination can easily and inadvertently be introduced into a manufacturing process. Vapor degreasing is a cleaning process that is generally highly effective and results in extremely low contact angles with very tight statistical distributions. One client came to us puzzled because she was getting higher than anticipated contact angle measurements after completing her vapor degreasing process. After conducting a root cause analysis, she learned that silicone-containing mats had recently been introduced into her measurement stations. (The mats had been ordered to help eliminate scratching of delicate parts.) The individuals who had ordered and started using the mats were unaware that the mats contained silicone. The silicone contained in the mats was outgassing particles into the environment, which subsequently contaminated surfaces in a way that led to adhesion failure.

As the above example illustrates, great care must be taken across the product's entire lifecycle and manufacturing process – beginning with the processing of incoming materials through cleaning and treatment and including final assembly or coating. Some examples of surfaces that are vulnerable to chemical contamination include silicon wafers used in electronics manufacturing, lenses used in photonics applications, and oil pans sealed using form-in-place gaskets used in automotive manufacturing – to name just a few.

Team members can also inadvertently introduce chemical contamination onto surfaces. A human fingerprint has a layer of oils and fatty acids that is about 1000 molecular layers thick. Residue from a person’s breath can be 100s of molecules thick.

Creating Optimal Environmental Conditions for Maintaining Chemically Clean Surfaces

Environmental conditions can affect chemical cleanliness in many ways, including absorption and physical contact.

Heat can accumulate in manufacturing environments from multiple sources, including internal cooling systems that cannot keep pace with hot outdoor temperatures and heat that is generated by manufacturing equipment being run at high speeds. Inadequate ventilation in a factory can also contribute to increased temperature levels.

In some instances, heat can cause a critical thermoplastic surface to deteriorate quickly. In these instances, an additive, which had been added to the thermoplastic intentionally (to enhance a particular performance element of the thermoplastic), may “bloom” to the surface. When an additive blooms to the surface, it causes the top few molecular layers of the surface to become contaminated. If it becomes contaminated, it can affect adhesion processes, including printing or laminating. Determining an appropriate ambient temperature for the entirety of your production process can help eliminate the opportunity for your surface to become inadvertently contaminated through the blooming of chemical additives. (A more comprehensive discussion of additive blooming in polymer films can be found here.)

Consideration should also be given to the location where the final surface cleaning and preparation occurs. (This is the process that occurs immediately before bonding, coating, sealing, painting, or printing your product.) If other manufacturing tasks, like molding, forming, or abrading, are being performed near this location, chemical debris can be released into the atmosphere from these manufacturing processes. Developing a method to capture this chemical debris and route it away from the surfaces being cleaned is critically important to maintaining the chemical cleanliness of surfaces.

Developing Appropriate Packaging to Avoid Contamination

With an understanding of the extraordinary chemical sensitivity of material surfaces, consideration should be given to how materials or components are packaged for the next step. Some packaging materials include components specifically designed to keep materials chemically clean. For example, certain ferrous and non-ferrous metals are vulnerable to rust. Packaging materials that include vapor corrosion inhibitors, like VCI paper, provide a packaging alternative for maintaining chemically clean surfaces for ferrous and non-ferrous metals.

For your particular process, it is necessary to understand if contamination is unintentionally being transferred to the material surface during the packaging and handling process. Seek out packaging and handling solutions that will mitigate these contamination sources.

Create Surface Cleanliness Specs for Incoming Materials

Developing production processes that protect materials at each CCP is important to the success of your adhesion processes. An additional quality safety measure is to include surface cleanliness standards on the specifications you send to vendors. Forward-thinking vendors, who are eager to stand out among the rest, may even include chemical cleanliness measurement criteria on their own Technical Data Sheets (TDSs). Here is one example of how Henkel, a world leader and innovator in adhesive formulation, turned to Brighton Science to develop a water contact angle measurement standard to include on their TDSs.

Contact angle measurements provide an unbiased, quantitative method for controlling surfaces — they also provide both your vendors and your internal team a common language and shared frame of reference for assessing the chemical cleanliness of surfaces. Maintaining verifiable “proof” of the chemical cleanliness of surfaces throughout your entire production process enables you to maintain both product quality and uptime while reducing scrap and downtime.

Consider which of your suppliers might be agreeable to developing technical specifications for chemical cleanliness for the products they provide to you. Ultimately, this provides a “win-win” scenario because incoming materials from the supplier will be accepted as being in compliance with your predefined specifications. This will help eliminate waste or rework for both you and the supplier — thus generating cost savings for both of you.

Optimize the power of next-gen connectivity with data & surface intelligence.

Take a Holistic Approach to Surface Cleanliness

Material handling best practices require that you take a holistic view of your entire manufacturing process — from how you confirm incoming raw materials are compliant to specifications through how your final products are packaged and shipped. Using water contact angles to validate the chemical condition of your surfaces at each CCP can help you discover any step in your process where your surface may inadvertently have become chemically contaminated. Discovering and eliminating new sources of chemical contamination can lead to your own Eureka Moments — and Brighton Science is available to help you through this process.

Discover in our eBook, "The Future of Manufacturing: A Comprehensive Guide to Advanced Adhesive Bonding Technologies & Methodologies," how utilizing water contact angles offers manufacturers a pathway to create, oversee, and uphold pristine surfaces across the complete product lifecycle.