Adhesion is crucial in microscopic and macroscopic worlds, yet it is an often-overlooked force. Adhesion acts as the invisible glue that unites objects, both massive and minute. Adhesion allows us to construct monumental structures like bridges, buildings, and airplanes. It enables us to glue wood pieces together to build furniture, attach materials to our clothing, and even create adhesive bandages that heal our wounds.

However, despite its immense power, adhesion is also delicate and fragile. It relies on a precise balance of forces and intricate processes to function effectively. Even the slightest disruption can weaken the bond and lead to failure.

This article will explore the science of adhesion, what makes up a surface, and how to control surface readiness for successful bond strength.

What is the Science of Adhesion?

In manufacturing, adhesive bonding takes many forms, but adhesion science principles are always the same. Adhesion science is a multidisciplinary field that studies interfaces' formation, characterization, and behavior where two dissimilar materials come together. It focuses on understanding the fundamental adhesion forces and intermolecular mechanisms that govern how these interfaces adhere and change over time.

Regardless of the task, be it welding metal adhesive joints, joining gaskets with industrial sealants, coating medical devices, printing on polymer surfaces, or painting cars, strong adhesion hinges on understanding and controlling three key elements.

The three things that must be controlled for adhesion to be successful are:

- The composition of the adhesive, coating, ink, or paint

- The application of the adhesive, coating, ink, or paint

- The quality of the bond surface

While the first two pose their own unique challenges, suppliers of adhesives and dispensing equipment have established well-defined strategies for managing them. However, the bonding surface, the third element, proves considerably more complex. Influenced by many variables and prone to undetected changes, it presents the most significant challenge to achieving optimal adhesion.

Watch the Video

Listen as Brighton Science's Founder and Chief Scientist, Giles Dillingham, explains the fragility of surface quality.

The intricate changes and inherent delicacy of material surfaces make them the most challenging aspect of adhesion to control and understand. Despite this complexity, harnessing control over these processes and unlocking their fundamental principles holds immense potential to enhance the predictability and reliability of adhesion.

What is a Surface?

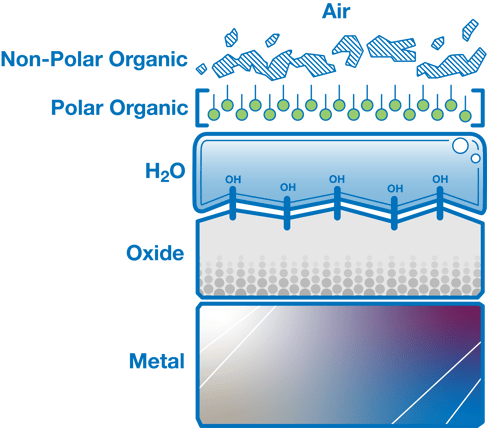

It seems like a simple enough question, but under closer examination, there's more to a surface than what meets the eye. As it relates to adhesion, a surface is an infinitesimally thin layer of molecules on top of the substrate. These molecules are what every operation, every piece of equipment, every person who handles the material, and the adhesives, coatings, paints, and inks interact with. The very air itself in the production facility can have a dramatic effect on the molecular level of the material surface and impact adhesive properties.

A molecular layer can be likened to the way LEGO blocks stack. All materials are made up of structures consisting of stacked molecules (individual LEGO blocks), and when something comes into contact with the material, it only interacts with the top blocks. Like LEGO blocks with small pegs, molecules need specific characteristics to properly connect with the molecules of the substance they are trying to bond with. A LEGO block cannot properly connect to a cinder block, and similarly, specific molecules cannot bond with other molecules, making good adhesion impossible.

A molecular layer can be likened to the way LEGO blocks stack. All materials are made up of structures consisting of stacked molecules (individual LEGO blocks), and when something comes into contact with the material, it only interacts with the top blocks. Like LEGO blocks with small pegs, molecules need specific characteristics to properly connect with the molecules of the substance they are trying to bond with. A LEGO block cannot properly connect to a cinder block, and similarly, specific molecules cannot bond with other molecules, making good adhesion impossible.

Surface preparation steps of an adhesion process are used to make the characteristics of the top few layers of molecules align with the ideal criteria for bonding with the adhesive, coating, paint, or ink.

The characteristics of the surface molecules involve their chemistry (i.e., if they are carbon molecules, oxygen molecules, or silicone molecules, etc.) and their composition (i.e., how much of each molecule exists on the surface and if it's concentrated in certain areas).

Rethink your adhesion manufacturing processes with Surface Intelligence.

How Do You Know What's on Your Material's Surface?

Characterizing the molecular layers based on chemistry and composition allows manufacturers to truly understand the aspects that make the science of adhesion work. So, it's vitally important to have this information or at least be advised by someone who does. Specialized equipment using sophisticated techniques like x-ray photoelectron spectroscopy (XPS) and Fourier-transform infrared spectroscopy (FTIR) are needed to map out what the surface truly looks like. This kind of equipment is only available in specialized materials science laboratories, but it's possible to correlate other techniques to the sort of data XPS and FTIR analysis offers.

Using equipment sensitive to the top few molecular layers is necessary to evaluate surface quality based on these chemical attributes accurately. There is accessible lab equipment available, like benchtop goniometers, that many companies utilize when XPS and FTIR are out of the question. Goniometers measure water contact angle to understand a material's wettability or surface energy.

Surface energy refers to how reactive a surface is and how ready to bond it is (surface readiness). The composition of a surface, including cleanliness and surface treatment, is determined by contact angles and surface energy. By measuring a water droplet's behavior on a solid surface, we can establish a correlation between this measurement and the surface energy of the solid. This correlation allows us to effectively control processes involved in preparing, treating, and cleaning surfaces for adhesive bonding and coating. Contact angle measurements are sensitive to the microscopic layers that the sophisticated lab equipment analyzes.

Most manufacturing companies require a solution that can measure surface quality with high accuracy directly on the production line rather than in a laboratory. Until recently, there were few options for this, but there have been significant advances in handheld and automated devices that verify surface quality using non-destructive contact angle measurements.

As the surface is altered throughout adhesion processes, these tools monitor and track those changes so manufacturers can respond immediately and appropriately to changes in surface chemistry that can impact chemical bonding.

To learn about the effects of surface roughness on contact angle measurements, read the article "Is Roughness as Important as Surface Cleanliness to Adhesion?"

Who Do You Look to for Surface Science Expertise?

So, it's clear now that three elements need to be fully controlled and understood to create an adhesion process that produces predictable, consistent results. Two of those are well understood and have been well managed by suppliers of adhesives, coatings, inks, paints and the manufacturers of deposition equipment like sprayers, dip-coaters, and the like.

The one element that most manufacturers typically do not have the expertise to fall back on is the quality of the material surface. Surface quality is challenging to measure and understand without knowing what actually makes a surface ready for good adhesion. The attributes that indicate readiness can differ from application to application, product to product, and production line to production line.

Since one of the most crucial adhesion elements is invisible to the eye, help is needed to detect subtle yet massively influential changes. For example, you can't truly know if the shelf you just installed is level without a leveling tool; you can't tell if your surface is ready for adhesion without help.

Read this blog article to learn what to look for when choosing a materials science expert to help with your adhesion process.

When you start talking about the things that affect the chemical characteristics of your surface, you begin to see how many variables there are that come into play and why what seems like a simple problem (i.e., my glue, paint, ink or coating didn't stick properly) is actually due to a complex web of uncontrolled factors. So, chemistry and manufacturing expertise matter a great deal. Solving this issue is possible when you know where to look.

Take a deep dive and learn all about adhesion science by reading the eBook "The Fundamentals of Adhesion."