Key Takeaways

- Surface roughness alone does not determine adhesion performance.

- Many benefits attributed to roughening actually come from unintentional cleaning during surface prep.

- Adhesion depends primarily on the chemical condition of the top one to five molecular layers.

- Surface aging and environmental exposure can degrade bondability even when roughness remains unchanged.

- Water contact angle measurements provide a practical, production-ready way to verify surface cleanliness.

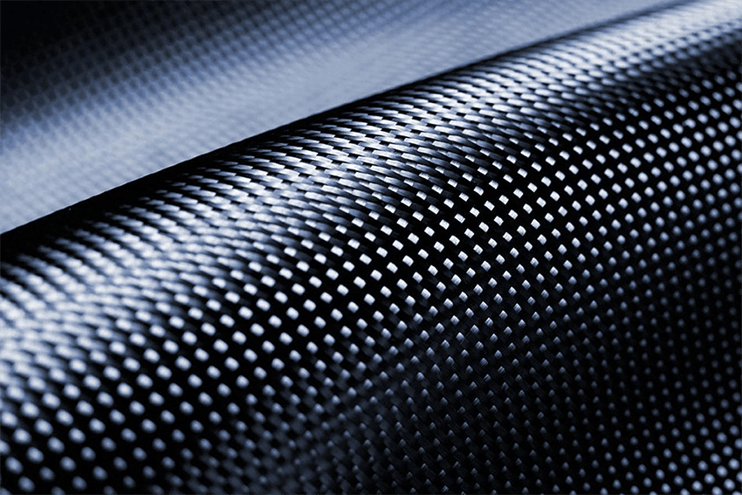

When manufacturers talk about surface preparation for bonding, coating, or painting, the conversation often centers on surface roughness. Sanding, blasting, etching, or laser treatments are routinely specified, and adhesive instructions frequently say to “roughen the surface thoroughly.”

The logic feels intuitive. A rough surface looks like it should provide more area for an adhesive to grab. But if roughness were truly the dominant factor, how could we explain strong bonds formed on polished metals, glass, or even atomically smooth silicon wafers?

That question exposes a common misconception in adhesion science.

Why Roughening Became the Default Approach

The traditional theory is straightforward. Abrading a surface creates peaks and valleys that increase the available surface area. More area means more places for an adhesive to attach, which should result in better adhesion.In practice, this explanation falls apart.

Adhesion failures still occur in processes where surfaces are aggressively roughened. At the same time, excellent adhesion is often achieved on very smooth substrates. The missing piece is that roughening rarely happens in isolation.

Most abrasion processes also remove contaminants, intentionally or not.

- Acid treatments clean metals while altering texture

- Mold release agents and oils are often removed before sanding plastics

- Even dry abrasion strips away at least some surface contamination

Tips from a Surface Scientist

If roughness were the deciding factor, a surface prepared today would bond just as well six months from now. In reality, storage time alone can destroy adhesion performance even though the surface texture never changes.

A Simple Thought Experiment

Imagine abrading a part, rinsing it properly, and then placing it into storage for six months. When you pull it back out, it looks the same. The roughness is unchanged.

But anyone with production experience knows that it will not bond the same way it did when it was freshly prepared.

So what changed?

The surface chemistry.

Surface Chemistry Is What Adhesion Actually “Sees”

Adhesion is governed by the chemical condition of the outermost molecular layers of a surface. These layers are highly reactive immediately after preparation, but they begin to change almost instantly.As soon as a surface is abraded:

- Molecular bonds are fractured

- Oxygen attaches to newly exposed sites

- Water vapor contributes hydroxyl groups

- Airborne hydrocarbons, silicones, and oils accumulate

Over time, a thin layer of contamination forms, reducing surface energy and chemical reactivity. This process continues as long as the surface is exposed, even in clean manufacturing environments.

From an adhesion standpoint, only the top one to five molecular layers matter. If those layers are chemically incompatible with the adhesive, no amount of roughness will compensate.

Tips from a Surface Scientist

Abrasion always changes chemistry, even when the goal is “just” to change texture. Broken bonds and added chemical species are unavoidable side effects of mechanical surface prep.

Roughening Can Introduce New Problems

Surface preparation methods can also add contaminants unintentionally.

For example, many sanding materials are coated with stearates to prevent loading and extend abrasive life. Those stearates can transfer to the surface and significantly reduce adhesion.

Without measurement, it is often impossible to know whether a surface treatment improved or degraded bondability.

How Do You Know a Rough Surface Is Actually Clean?

This is where water contact angle measurement becomes essential.Contact angle measurement is highly sensitive to contaminants that interfere with adhesion. It provides:

- An objective, quantitative assessment of surface cleanliness

- Direct feedback on real production parts

- Sensitivity to chemical changes invisible to visual inspection

A common concern is whether surface roughness distorts contact angle readings. The practical answer is that in most manufacturing scenarios, chemistry dominates the measurement.

If surfaces have similar roughness profiles and lack extremely sharp features, differences in contact angle primarily reflect differences in cleanliness, not texture.

Tips from a Surface Scientist

Roughness effects matter most when liquid drops become pinned on extreme surface features. For typical bonded surfaces, chemical differences outweigh roughness effects by a wide margin.

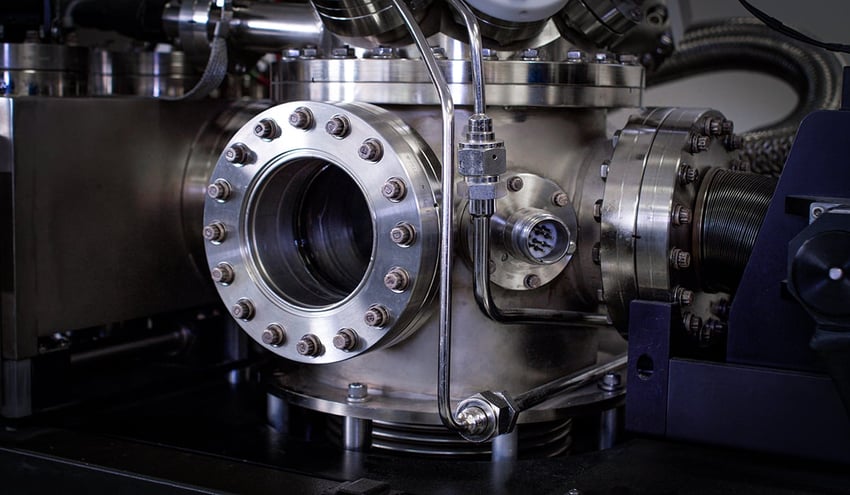

Measuring Rough Surfaces Reliably

Traditional goniometers often struggle on textured surfaces due to drop pinning during liquid deposition. This can artificially inflate measured contact angles and mask true surface condition.

The Surface Analyst™ addresses this with Ballistic Drop Deposition™, where nanodroplets impact the surface with kinetic energy that advances the drop edge over surface asperities. This produces round, stable drops that behave as if the surface were smooth.

The result is consistent, reliable measurements across a wide range of surface textures.

What Really Matters for Adhesion

Surface roughness is meaningless if the surface chemistry is wrong.- A chemically clean, glass-smooth surface can form an excellent bond

- A heavily roughened but contaminated surface will fail

- Even trace amounts of mold release or oil can completely eliminate adhesion

Roughness can support adhesion, but it cannot replace cleanliness.

Want to understand how your surface preparation steps really affect adhesion? Explore how surface measurement can bring consistency and control to your bonding processes.

Frequently Asked Questions

Q: Is surface roughness necessary for good adhesion?

A: Not always. Many smooth surfaces bond extremely well when they are chemically clean and properly prepared.

Q: Why does sanding often improve adhesion?

A: Because sanding frequently removes contaminants. The improvement is often due to cleaning rather than increased roughness.

Q: Can surface aging affect adhesion even if roughness stays the same?

A: Yes. Chemical changes caused by oxygen, moisture, and airborne contaminants degrade bondability over time.

Q: Does surface roughness affect contact angle measurements?

A: In most manufacturing cases, chemical differences have a much larger impact than roughness, especially when surfaces have similar texture profiles.

Q: How can manufacturers verify surface cleanliness on the line?

A: Water contact angle measurement is a practical, objective method that directly correlates with adhesion performance.