Adhesion problems tend to appear in the manufacturing process and then overstay their welcome. The chronic nature of so many adhesion issues is due to factors that many manufacturing companies are oblivious to. That’s not to fault the manufacturers. Until recently, there hasn’t been a reliable way to deal with these issues head-on.

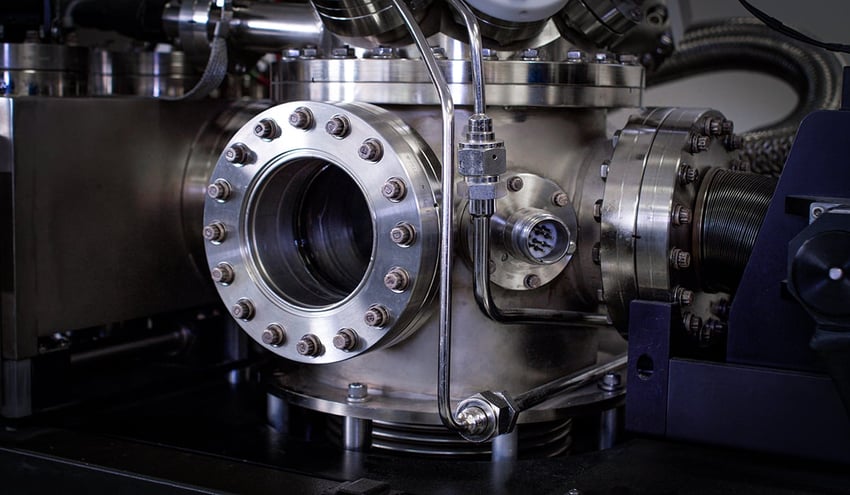

Manufacturers can see the damage caused by persistent failures but cannot make the appropriate moves to eliminate them because linking the failures back to a fundamental adhesion problem isn’t possible when doing business as usual. This gap comes from a lack of useful root cause analysis equipment and procedures that can fill in the missing pieces.

Adhesion failures settle into production and wreak havoc, leading to:

- Untenable scrap rates

- Production delays due to employees devoting time and effort to putting out fires caused by failure

- Delays in new product scale-up, from the Research and Design stage to the production line

- Rework involving re-doing steps that didn’t work the first time

- Recalls of products that begin failing after being sent to market and are deemed unsafe

- Returns due to customer dissatisfaction

- And many more…

The causes of these issues can be very difficult to uncover. The struggle to find the root cause of the failure that redounds to the setbacks listed above can keep a company from being able to move forward in a meaningful way. Manufacturers with chronic issues stemming from imperfect adhesion are essentially trying to run with cement shoes.

Removing the burdens of unsolved adhesion problems and breathing new life into adhesion processes that have accepted failures for too long is possible.

Understand Your Process to Control Your Process

Every manufacturer who wants to eliminate production problems caused by adhesion issues needs to understand their material system and adhesion process fundamentally.

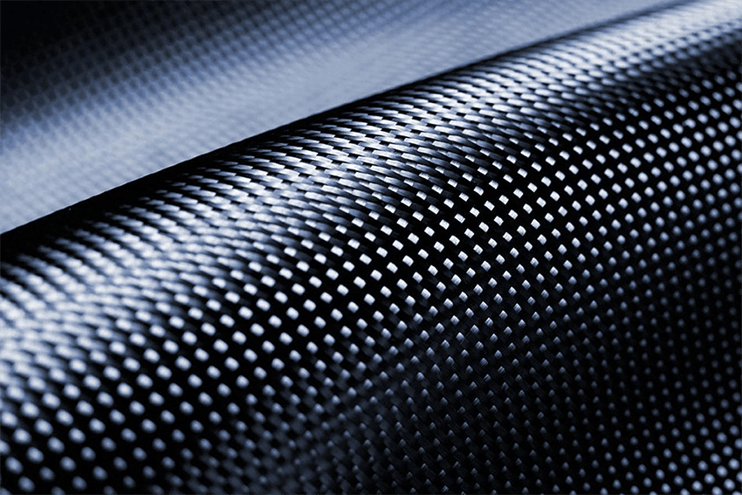

The material system (the substrates being bonded, coated, printed on, painted, or cleaned, as well as the adhesive, coating, paint, or ink being applied) needs to be appreciated as having chemical properties that need to interact in precisely prescribed ways in order for adhesion to be successful.

Often, these chemical characteristics are examined and defined in the research and development lab, but when products are scaled to production, this appreciation can be lost in the transition.

The common approach to product failures is to look almost everywhere except for the material surface. Adhesion is not commonly grasped as the probable antecedent of the problems that cause rework, recalls, and mounting scrap rates. Predictable adhesion is possible when a material surface's top few molecular layers are controlled to meet specific chemical criteria. This control needs to exist and be monitored throughout the adhesion process.

Acknowledging how the entire adhesion process affects the chemical characteristics of the material surface every time it is modified is critical to controlling all the elements that lead to perfect adhesion. Without this vital and foundational understanding of adhesion, failures will become and remain chronic.

Rethink your adhesion manufacturing processes with Surface Intelligence.

It Takes a Village

A major hurdle to overcome when implementing solutions to these chronic problems is the need to involve many stakeholders. The groups that need to be mobilized to tackle systemic issues are often interdepartmental and cross-disciplinary. Building consensus among these groups can be difficult, so delays in finding solutions can be tied up in trying to secure buy-in from all necessary parties.

In anticipation of this difficulty, it’s a good idea to conduct a root cause analysis that begins by examining how strengthening the adhesion process can mitigate known issues. Systematic root cause analysis applied to the entire adhesion process and carried out by experts is the first step to fortifying an adhesion process against chronic failures.

Key fundamentals to developing an understanding of the material system and adhesion process (like what was discussed above) need to happen before consensus among the stakeholders is achieved, including the following:

- Knowing the chemical characteristics of every component, including:

- The baseline substrate

- Any primers used

- Activation techniques employed

- The coatings, paints, inks, or adhesives

- Knowing how the materials are moving through the process and how the steps are organized

- Knowing the chemical changes that are occurring at each step and how time not in production (storage, shipping, etc.) is affecting the surface

The depth of knowledge required to understand these things thoroughly and how they impact a precise adhesion process necessitates expertise that may not be available within a manufacturing company. Therefore, it is often necessary to look outside the company to evaluate an adhesion process and conduct a holistic root cause analysis.

This analysis will uncover where and how surfaces are not getting fully and properly prepared for adhesion, leading to chronic failures. To eliminate the failures, manufacturers must implement a plan of chemically sensitive inspection at every Critical Control Point (those areas where the surface changes in any way whatsoever). These inspections will validate current processes, verify the surface state of the material as it goes through the adhesion process, and monitor changes that are outside of the required specifications for cleanliness and chemical characterization.

Doing all of this is a major undertaking, but manufacturers do not have to do it alone. The experience, expertise, and equipment are available to get to the heart of adhesion failures and uproot them for good. The efficiencies that can be built into an adhesion process will drastically reduce delays, scrap, rework, and guesswork. When you can minimize adhesion failure, you have a real impact on production rates and the economics of manufacturing.

To learn more about how adhesion might negatively impact your manufacturing processes, read the eBook "What is Adhesion?"