In today's highly competitive manufacturing environment, controlling the adhesive process is vital to ensuring product quality, consistency, and efficiency. Understanding the Critical Control Points (CCPs) within the adhesive process is essential for maintaining control and achieving desired product characteristics.

This blog post will explore the concept of Critical Control Points and provide valuable insights into how to identify and manage them effectively. Whether you are involved in producing consumer goods, industrial products, or packaging materials, mastering the manufacturing process and controlling your adhesive process can significantly impact your bottom line.

What are Manufacturing Process Controls?

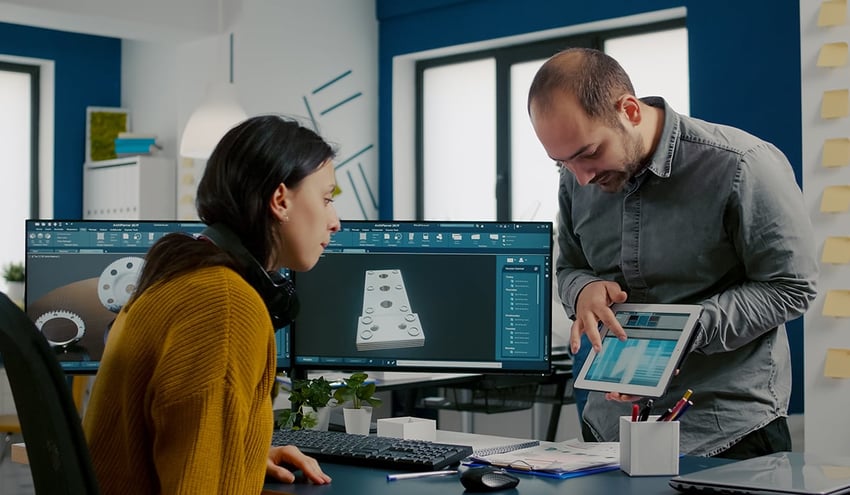

Manufacturing process control encompasses integrating technologies and methodologies employed to oversee manufacturing operations. This entails the essential hardware and software elements required for monitoring, regulating, and enhancing production.

Manufacturing process control aims to generate products that meet or surpass quality benchmarks while reducing waste and maximizing effectiveness.

Manufacturers can leverage an array of sensors, controllers, actuators, and other devices to gather data on the production process, which is subsequently analyzed to pinpoint trends and challenges that can be rectified to enhance quality and efficiency. But how do manufacturers leverage manufacturing process controls to manage adhesion processes effectively? We call this new methodology ‘Critical Control Points.’

What is a Critical Control Point?

Instilling confidence in the manufacturing process starts with pinpointing and examining the Critical Control Points of the adhesion process. Process variables within each production process can impact the success of adhesion, and some may not be immediately obvious.

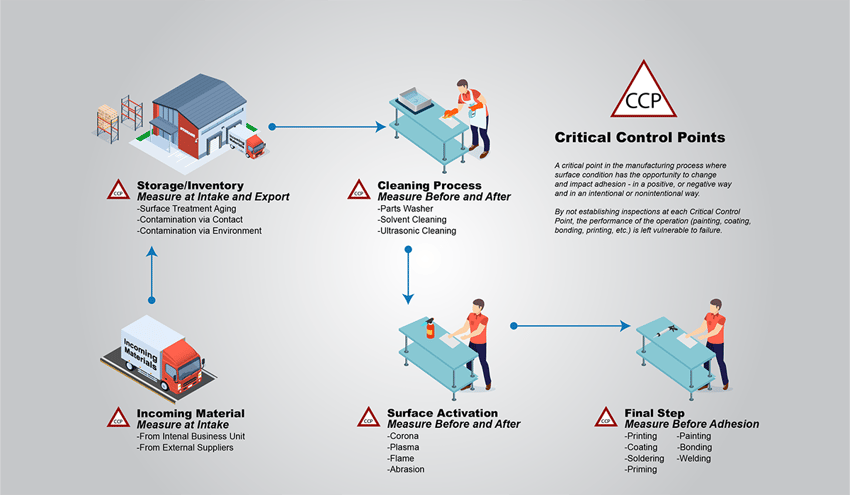

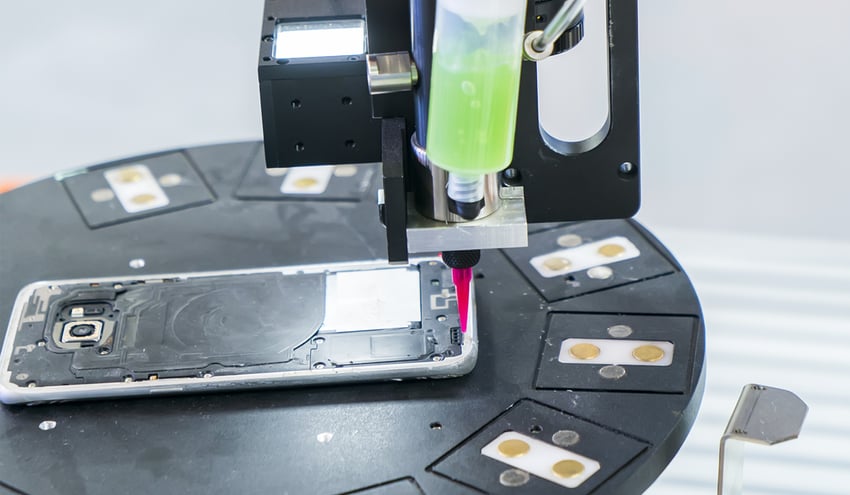

A Critical Control Point (CCP) is any point in the manufacturing process where a material's surface condition can change—intentionally or unintentionally—and impact adhesion in a positive or negative way.

Implementing Critical Control Points in Manufacturing Process Management

As defined, CCPs are the pivotal inputs in any manufacturing process where components are stored, washed, transported to the facility, treated, bonded, coated, painted, installed, etched, abraded, cleaned, and more.

Inadequate monitoring processes and management of these CCPs could lead the entire manufacturing business toward failure without detection. Their designation as critical underscores their significance.

Without quantifiable numbers at each of these points, the process's success or failure becomes a matter of guesswork.

Where are Critical Control Points found?

Potentially everywhere. It's logical to look at points in the manufacturing process where obvious changes are taking place to your material surface. Still, anytime there is the possibility of change to the surface state, there is an opportunity to take a closer look.

When raw materials or parts/components come into the manufacturing facility from the supply chain, any number of contaminants present at that point need to be handled directly. If a part remains in storage for a period of time, the previous surface treatment may deteriorate, rendering it susceptible to contamination. These are two (of many) examples of Critical Control Points within industrial processes that aren't immediately obvious.

Rethink your adhesion manufacturing processes with Surface Intelligence.

How Are Control Critical Control Points Controlled?

Well, until now, you haven't been able to.

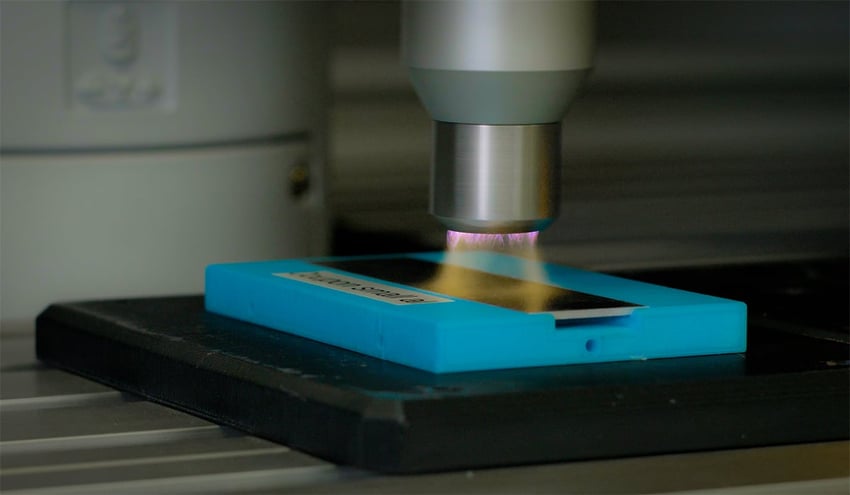

If these CCPs do not have a quantifiable spec to aim for when altering the surface condition of your material, then how can success be measured? And if you can't measure what occurs at these CCPs, how can you manage it?

It may sound simple, but the answer is quite frightening because, more often than not, the truth is - you can't. You can't manage what you can't measure.

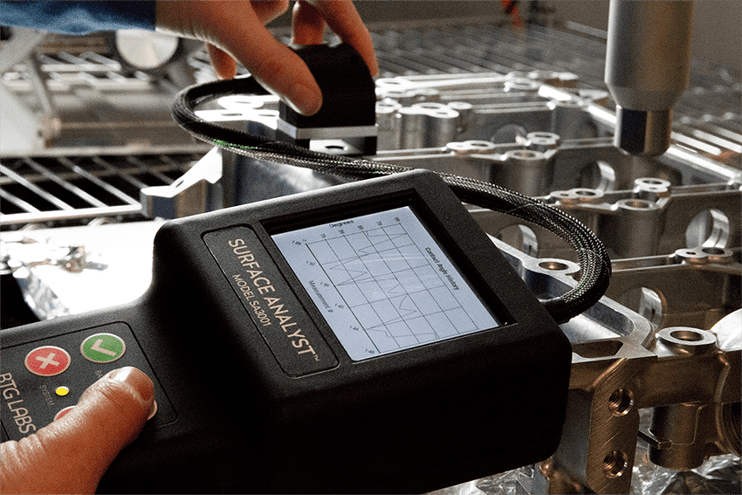

If you don't have quantifiable metrics defined for each CCP, you are missing vital information and are leaving your process vulnerable to adhesion failure. But there is hope! By implementing quality control methods like water contact angle measurements before and after each Critical Control Point, any deviations can be swiftly identified, allowing for prompt root cause analysis and corrective action.

We have over 30 years of experience uncovering Critical Control Points and equipping companies with process control systems, instrumentation, and the knowledge they need to regain manufacturing control and ensure adhesion. We can help you discover your CCP metrics and learn how to apply them to optimize your manufacturing processes at a high quality.

Learn how to establish an inspection method and a networked communication method that connects all the dots and ensures seamless manufacturing process control of adhesion—from your suppliers all the way through to the end product. Partner with us to optimize your adhesion process and shore up your Critical Control Points. Download the eBook “The Future of Manufacturing: A Guide to Intelligent Adhesive Bonding Technologies & Methodologies."

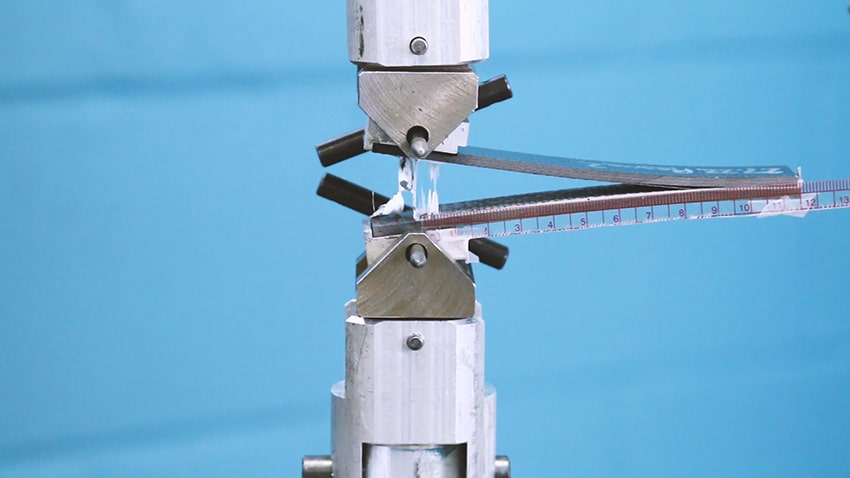

.jpg?width=850&height=495&name=metal-brazing-copper-component%20(reduced).jpg)