Disclaimer: This article is NOT about COVID-19; it is about a surface treatment process for better surface preparation and adhesion properties in manufacturing.

If you're looking for information about cleaning, here's an article that discusses the difference between biological cleanliness and chemical cleanliness: COVID-19: Biological vs. Chemical Contamination in Manufacturing.

This article will explore corona treatment, how it works, and how manufacturers must measure this pre-treatment method to ensure that their substrates are properly prepared to laminate or accept a coating, ink, or paint.

What is Corona Treatment?

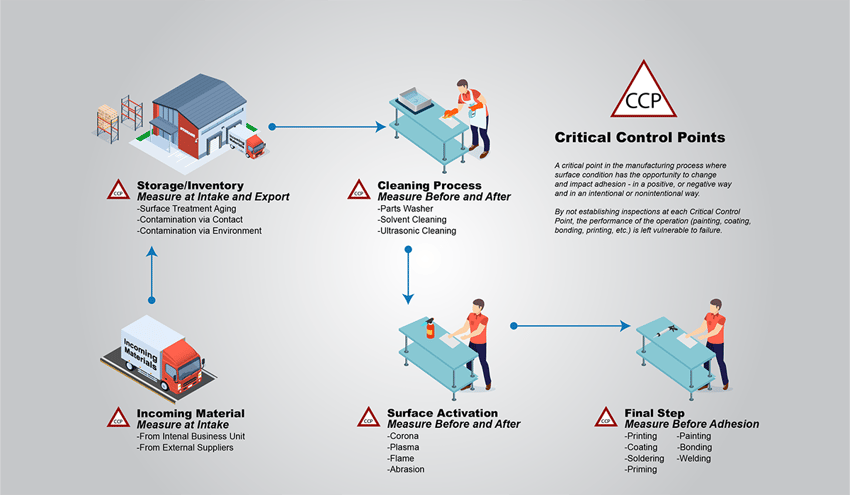

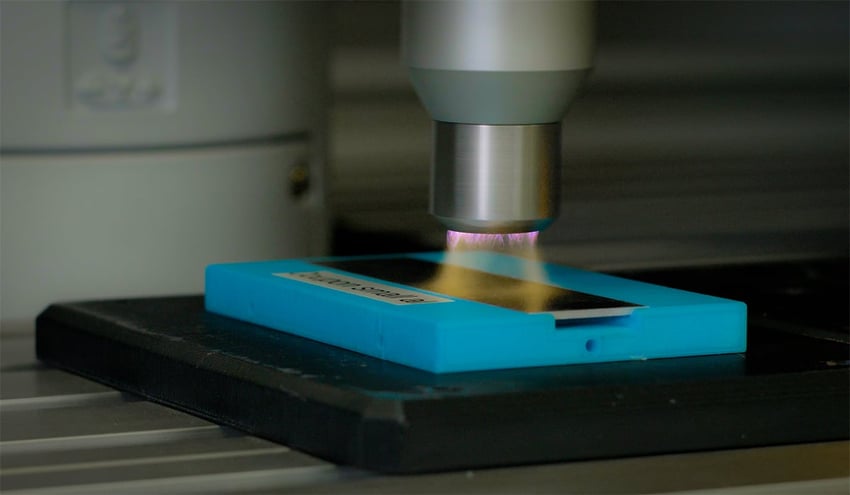

Corona treatment is one of the most commonly used methods in adhesion processes for preparing materials like film and polymers manufactured on large rolls. Corona treatment is used to activate a material’s surface or create a molecularly amenable condition on the substrate for the successful adhesion of a rolled material requiring coating, printing of ink, laminating, or painting.

What is the Difference Between Plasma Treatment and Corona Treatment?

Both plasma treatment and corona treatment are surface modification techniques used to improve adhesion for coatings, but they have some key differences:

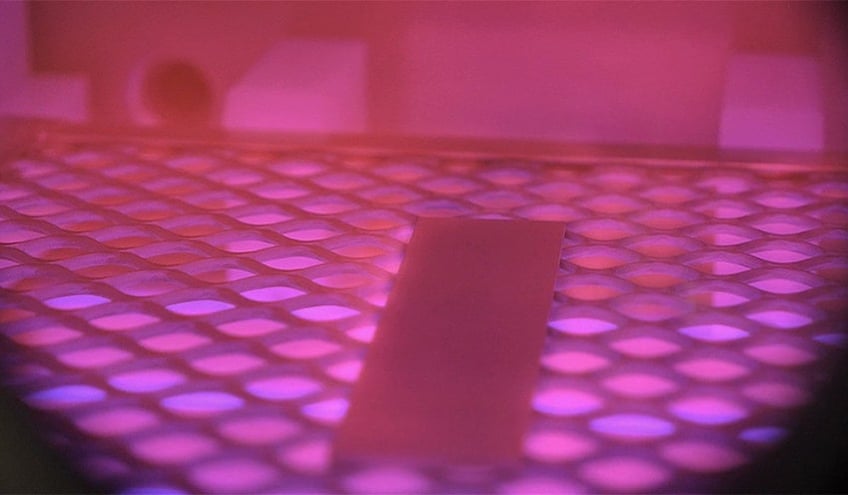

Corona: Corona treatment employs an electrical discharge in ambient air to modify the surface energy of polymer substrates, thereby facilitating pre-treatment. This technique is prevalent in converting and extrusion industries.

Plasma: Plasma treatment leverages the unique properties of plasma, the ionized state of gas, to modify material surfaces. During this process, the controlled introduction of gases like argon, nitrogen, or helium facilitates various surface modifications, including pre-treatment and altering surface energy. These modifications aim to create a low surface energy and enhance the adhesion of coatings, printing, and other downstream processes.

Rethink your adhesion manufacturing processes with Surface Intelligence.

How Does Corona Treatment Work?

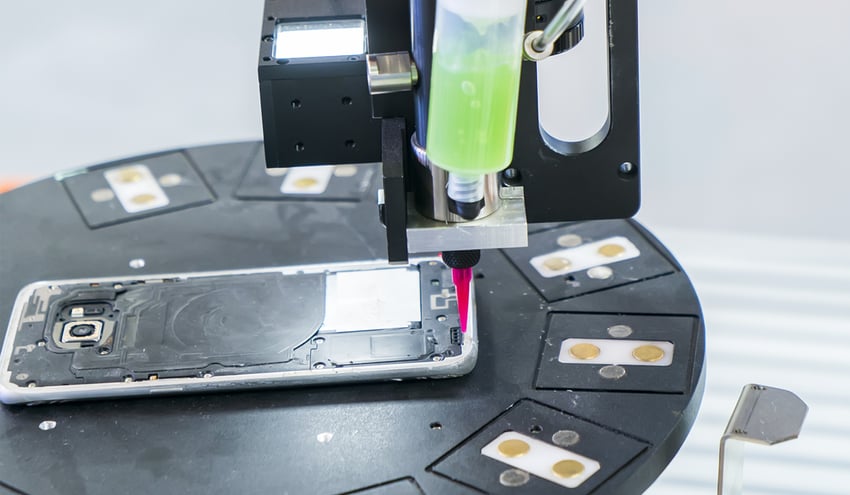

Corona treating works by discharging high-voltage, high-frequency electricity from an electrode in a ceramic tube that runs the length of the roll of material needed to be activated. The electricity is sent through the material to an electrically grounded metal roll called the treater roll, which is wrapped around the material. This interaction between the electrode and the metal roll creates a visible flash on the surface of the plastic film roll as it moves between the two components. However, the effects of corona treatment are completely invisible to the human eye.

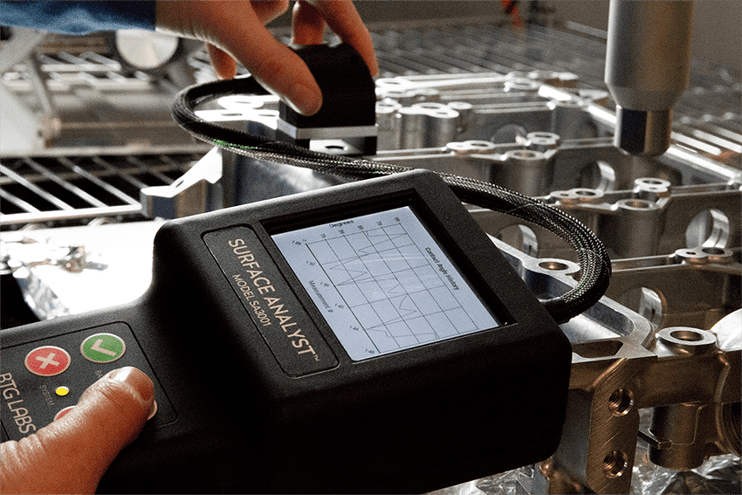

As was stated earlier, this treatment alters the surface at a chemical level. Therefore, there is no visual test that could ever offer confidence that the treatment was successful at creating a chemically clean surface. Only a measurable, quantitative measurement gives the data necessary to take action.

There are many different providers of corona treatment systems, each with variations to the standard setup. Even with the diversity of corona treaters available, there are specific variables within every corona treatment process that must be fully understood and controlled to get the best results.

In most corona surface treatment systems, the material roll travels at a controlled speed over the stationary treater roll to ensure uniform surface activation. However, a phenomenon called electrical pinning can occur. The static electrical force attracts the treated material to the treater roll during treatment. If not addressed, this attraction can cause the material to pull on the treater roll, potentially leading to wrinkling. To prevent or mitigate wrinkling caused by electrical pinning, additional parameters like tension and material wrap on the treater roll can be adjusted through devices like a drive shaft and a nip roll.

Often, wrinkling is undetectable by merely observing the roll through a visual inspection because the rotating of the treater roll is so subtle that it creates minute waves in the roll that still impact the uniformity of the corona treatment. So, once again, it is always necessary to measure the treatment level across the entire roll and track changes so adjustments can be made accordingly.

Similarly, modifications to the treatment power (measured in watt density, which is the watts per foot per minute of treatment) are necessary depending on what the coating or adhesive being applied to the film is made up of. The corona treatment's watt density controls the surface energy level of the material being treated. So when this parameter is adjusted, it determines the condition on the surface of that is optimal for bonding.

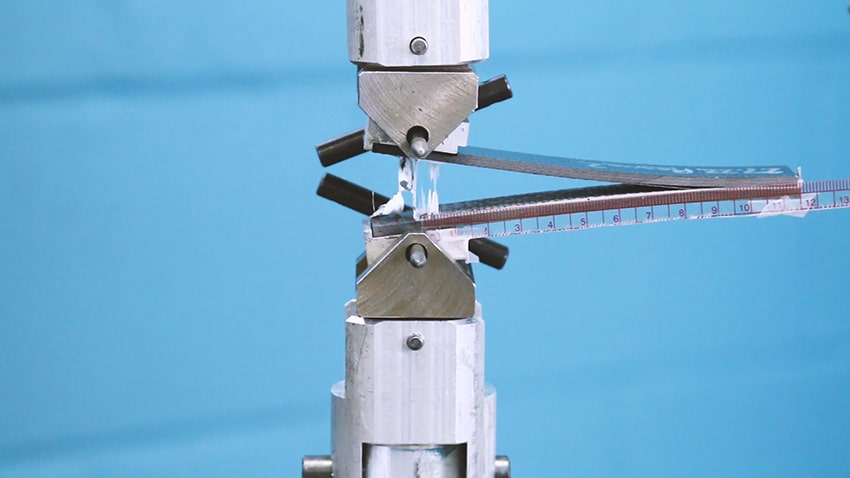

The Risks of Not Measuring Corona Treatment

Water-based coatings require higher surface energy than solvent-based ones, and UV coatings require even higher surface energy than water-based coatings. Not all coatings in each of these categories have the same pre-treatment needs. Not knowing what the exact range of treatment is necessary to guarantee adhesion can lead to under- or over-treatment. Over-treating a surface can be just as detrimental to adhesion as not prepping the surface enough. It is critical to implement quantifiable supply chain controls to eliminate the risk of treatment outside of established treatment specifications.

Additionally, it’s necessary to establish and measure a material's baseline chemical state before treatment so that it can be compensated for when the treatment is applied.

How to Eliminate Risk Within Your Corona Pre-Treatment Process

Subtle changes in supplier-provided materials or storage conditions of these materials and the coatings may necessitate adjustments to previously established treatment protocols to ensure continued efficacy. Past success with corona treatment does not guarantee its continued efficacy for subsequent pre-treatments. Therefore, ongoing monitoring is essential to verify consistent effectiveness.

Adhesion failure is a recurrent challenge encountered by many organizations, impacting applications ranging from minor inconveniences (e.g., improper ink adhesion on polymer labels) to critical safety concerns (e.g., coating malfunction leading to sensor failure in automotive components). Identifying and addressing the root causes of such failures can be complex, particularly without the expertise of adhesion specialists or specialized surface quality monitoring equipment.

Organizations utilizing corona treatment, plasma treatment, or other pre-treatment processes can benefit from implementing an intelligent surface quality measurement platform like BConnect. This innovative platform facilitates the measurement and collection of critical data, enabling proactive risk mitigation of adhesion failures and verifying optimal surface treatment performance.

Whether your organization or its customers face recurring challenges with adhesion failure, integrating surface quality measurements as a Key Performance Indicator (KPI) within your surface treatment quality program offers a future-proof approach. This proactive measure empowers data-driven decision-making, ultimately enhancing the effectiveness of your surface treatment processes and mitigating the risk of adhesion failures.

Don’t let adhesion failure determine when you act. Fix the problem before it starts. Download the "The Future of Manufacturing: A Guide to Intelligent Adhesive Bonding Technologies & Methodologies" eBook. This guide provides critical insights into eliminating guesswork around adhesion so manufacturers can achieve consistent and successful results.

.jpg?width=850&height=495&name=metal-brazing-copper-component%20(reduced).jpg)