Innovation is a word you hear tossed around frequently in various industries. Many organizations pursue innovation relentlessly as the key to their success and to gaining or maintaining a competitive edge. But innovation can be elusive for organizations that don’t quite know how to support it. As a result, some simply throw money at the challenge.These organizations may purchase the latest tools and equipment with the well-intentioned goal of gaining a competitive manufacturing advantage through cutting-edge technology without really knowing how to leverage the equipment.

The Innovative Advantage: Gain Insight and Equipment

By definition, innovation is doing something new that increases risk. Innovation requires a new approach, and, yes, often, new equipment is needed. But more importantly, innovation requires insight into what needs to be achieved and how.

New equipment is not enough if you don’t know how to use it best.

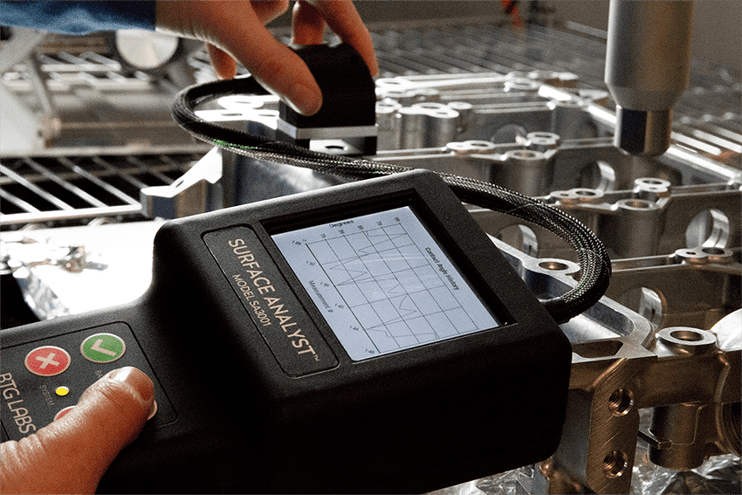

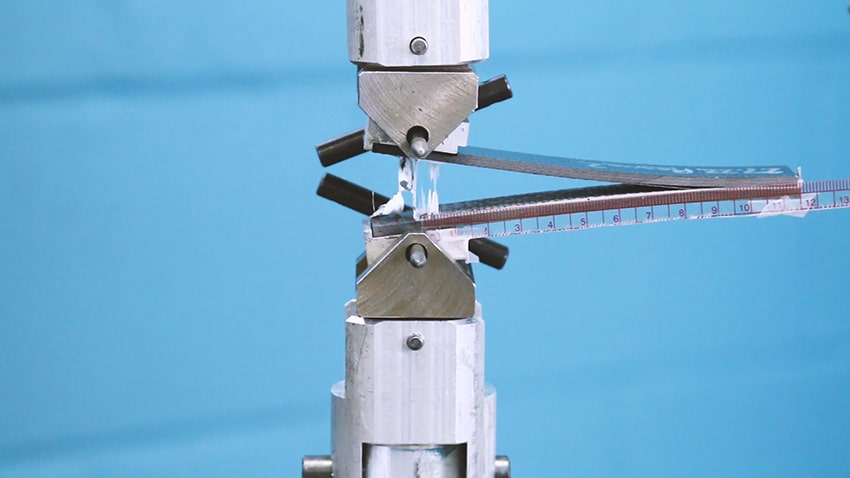

Rethink your adhesion manufacturing processes with Surface Intelligence.

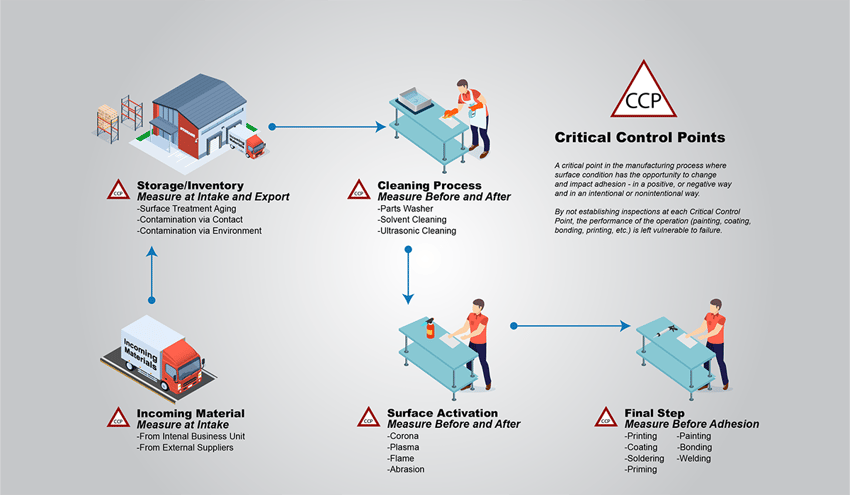

Part of the challenge is that the people responsible for a manufacturing operation are typically technical problem-solvers. They identify a trouble spot and then develop a solution to eliminate it. As they become recognized as problem-solvers, they often get rewarded for their ability to focus on specific problems and effectively resolve them. Unfortunately, what is often missed or ignored is the root cause of the problem, which can be complicated and difficult to identify and eliminate. As a result, these underlying issues can continue to cause problems for the organization and negatively affect the bottom line.

What’s really needed is not just new, cutting-edge equipment but insight into how to solve problems with it that can only come from expertise and experience. And this can often be acquired from the very same company that provides the equipment.

How to Develop a Best-in-Class Manufacturing Approach

Best-in-class manufacturing starts by creating an environment that encourages creative thinking and a can-do approach to solving problems by attacking the root cause, not just fixing the symptom. A truly innovative, best-in-class manufacturer will take an approach that includes these elements:

Open innovation takes advantage of creative, useful ideas from various sources, including internal personnel and vendors, clients, customers, and consumers, to help gain insight from different perspectives and experiences.

Cross-enterprise sharing, a practice known as “Yokoten,” is part of the Japanese Kaizen business strategy that espouses continuous improvement up and down an organization. Yokoten loosely translates as “best practice sharing” and encourages capturing information and knowledge across the enterprise.

Solution provider partnering means viewing solution providers as more than just vendors – envisioning them instead as stakeholders in the company’s success because when the company succeeds, so does the solution provider. A good example of this is the relationship between Colgate-Palmolive and machine-learning software provider Augury, which provided the technology and know-how to help C-P monitor and manage production lines instead of the personal-care product manufacturer investing time and money in creating its own technology.

The Advantages of Open Partnering

So why do best-in-class manufacturers take this open approach of partnering with solution providers? Because they often have much deeper expertise that is quickly and readily available. By providing existing resources and fresh perspectives, solution providers can speed up and focus innovation to bring new ideas, technology, and processes to bear manufacturing challenges.

By embracing external insights and assistance, your company can:

1. Reduce Risk

Simply buying new equipment does not ensure innovative success. It’s important to identify and incorporate appropriate outside resources to provide the valuable tools you need to innovate and succeed.

2. Quickly Gain New Skillsets

By taking this approach, your team learns from the solution provider and their deep experience and understanding rather than wasting time, money, and resources reinventing the wheel internally.

3. Gain Faster Value From Your Solution

The right solution provider has everything already in place to rapidly bring problem-solving and innovation to bear on your problem. The fast you obtain your solution and put it to work, the quicker you achieve payback on your investment.

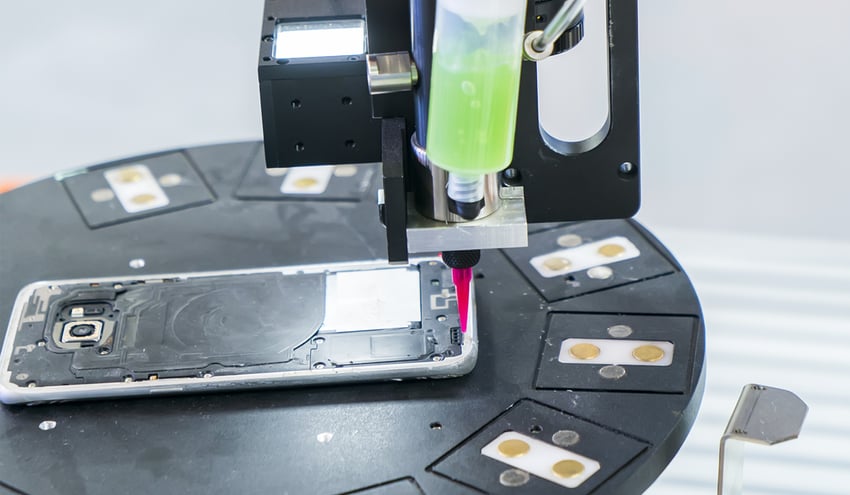

Optimize the power of next-gen connectivity with data & surface intelligence.

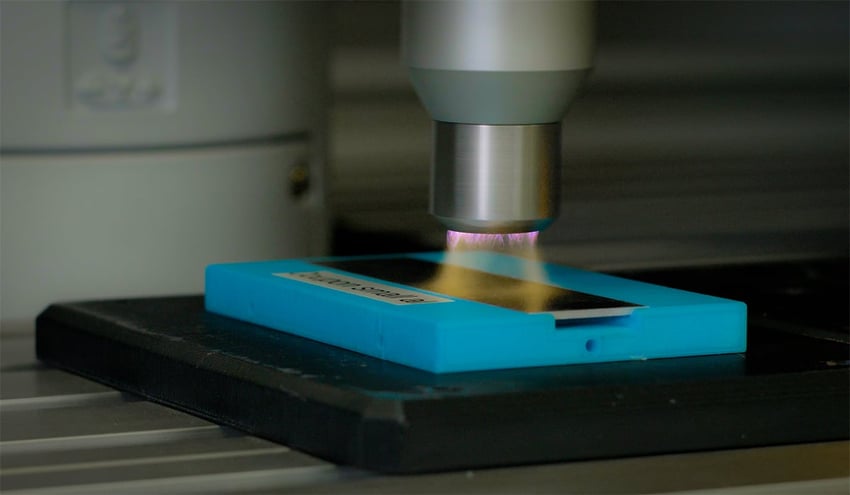

By taking advantage of the assistance and expertise of your equipment provider, you can dramatically increase your ROI and decrease risk. Everything speeds up to create a substantial competitive edge: innovation development, implementation, and investment payback. Leveraging your equipment solution provider's intellectual and technological resources will accelerate your understanding and ability to utilize new technology for streamlining production and significantly improving overall product quality and performance.

Learn how to equip your manufacturing processes with a secret weapon that gives your company a significant competitive advantage. Download our eBook to learn more: The Future of Manufacturing:

A Guide to Intelligent Adhesive Bonding Technologies & Methodologies.

.jpg?width=850&height=495&name=metal-brazing-copper-component%20(reduced).jpg)