Today, we're much more aware of the surfaces we touch and the potential unseen threats that linger on them. This focus on surface interaction isn't new for manufacturers, who've long considered how surfaces interact with our skin and the environment. Think about it – the simple act of touching something can transfer germs or leave traces behind.

For years, scientists have been developing "self-cleaning" coatings. These often work like a type of hydrophobic shield, repelling liquids quickly and carrying away dirt, dust, and other unwanted particles.

Oleophobic coatings take a similar approach, but their specialty is repelling oils. Our hands naturally leave behind grease and oils on everything we touch, especially frequently cleaned surfaces. That's why proper glove use and surface cleaning are crucial during manufacturing.

These oleophobic coatings are particularly beneficial for medical devices that require low-friction surfaces and touchscreens on electronic devices. Imagine oil and water—they don't mix! Similarly, oleophobic coatings don't prevent fingerprints or smudges, but they make wiping them away with a dry cloth much easier. The oil can't bond to the surface, so it gets lifted instead of smeared.

It's important to remember that these coatings aren't necessarily antiviral or antibacterial – they don't actively kill germs. However, their oil-repelling nature makes cleaning significantly easier.

Researchers are even exploring ways to use these same oleophobic principles to create surfaces that resist viruses like COVID-19. This includes targeting the "spike glycoprotein" that allows the virus to cling to surfaces. We also have other tools in our arsenal, like antimicrobial fabrics with silver or omniphobic coatings that repel many substances.

Now, let's delve a little deeper into the world of oleophobic coatings for manufacturers. While adhesion is crucial, ensuring long-lasting effectiveness is a key challenge. Ideally, manufacturers want to confidently communicate a product's lifespan, including how long the oleophobic coating will remain functional. For instance, if a device's electronic components are designed to last two years, they need clear evidence that the oleophobic coating will keep working just as well for that entire period. Unfortunately, achieving this consistent performance presents some unexpected complexities.

How Do Oleophobic Coatings Work?

Oleophobic coatings come in a few varieties, but the key characteristic is the inclusion of a fluorocarbon base or another very non-polar collection of molecules. Non-polar molecules have no charge to them and therefore are not attracted to or by other molecules. Silicon, fluorine, and chlorine atoms are often formed into polymeric films to create a barrier on the surface of materials that manufacturers don’t want anything to stick to.

These coatings have many applications because they are so lubricious and have extremely low surface energy (or chemical reactivity). A popular fluoropolymer, PTFE, is used to make medical devices that do not transmit bacteria but also make the business of inserting metal components less traumatic to the patient’s body.

Fluoropolymers are also used in the automotive and aerospace industries since oil is such a present element in these fields. These oleophobic coatings help keep oil from getting where it shouldn’t and adds a low-friction surface that can help stave off scratches and wear that would lead to moisture damage and corrosion.

Oleophobic coatings can be in the form of nanoparticle coatings, which are extremely thin films deposited through plasma chemical vapor deposition (CVD). This process takes place in a chamber where the coatings are introduced in a gaseous state and bonded to the surface of the glass, metal, plastic, or other material that needs to be coated. These coatings are invisibly shallow and transparent, so they’re perfect for optics and photonic applications. They were initially developed within the ophthalmology field.

How to Apply Oleophobic Coatings?

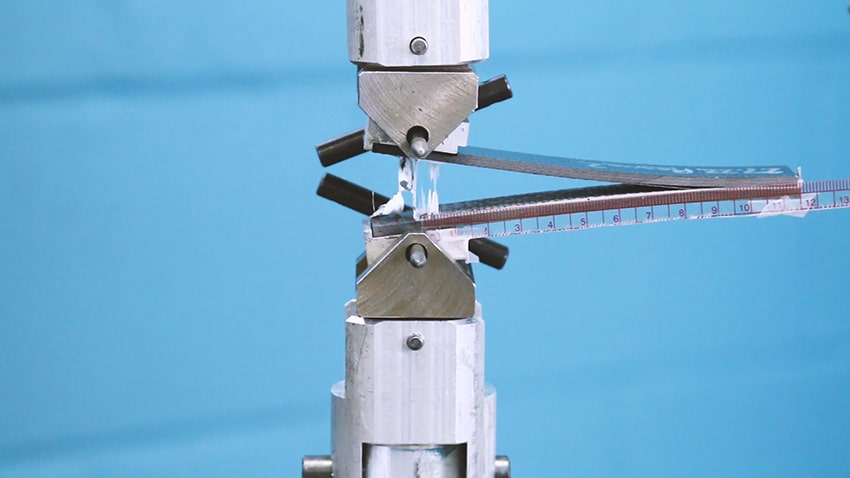

If the surface beneath the coating isn’t properly prepared, the chance of a long life for the coating is greatly diminished. Since these coatings are made to be repellent, getting them to adhere to surfaces can be difficult yet crucial. Using an abrasive and a chemical etch can create a chemically compatible surface that will bond well with the coating.

Any residues, especially oily ones, on the surface before the CVD operation are extremely detrimental contaminants to this process. Cutting fluids, greases, and other common oils found in manufacturing environments can cause inconsistencies in coating thickness due to dewetting - when a coating pulls back due to incompatibility with a substance on a surface.

Also, due to the chemical needs of oleophobic coatings, a primer might be needed to promote adhesion, but even then, the cleanliness of the underlying material is crucial for the primer to stick properly.

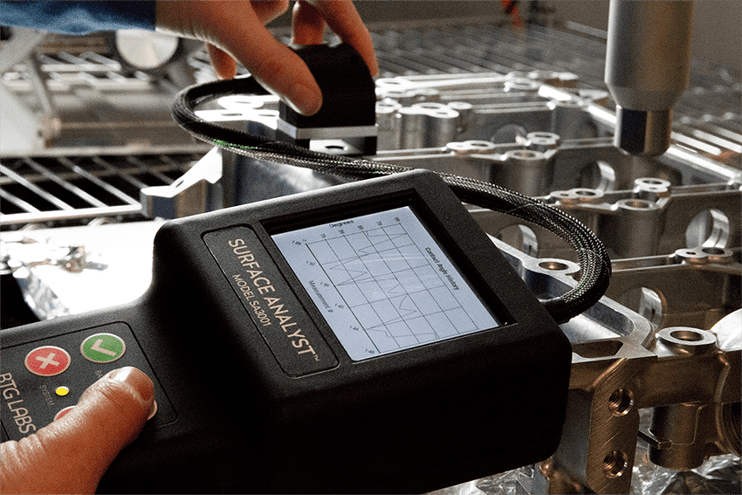

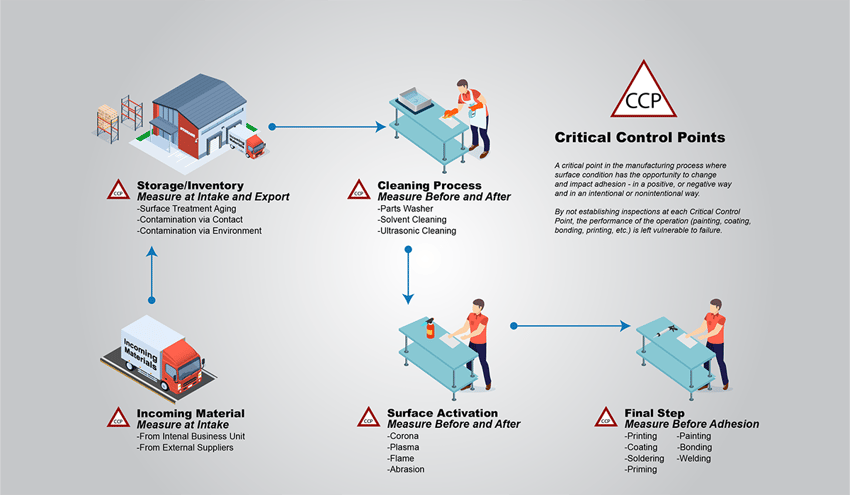

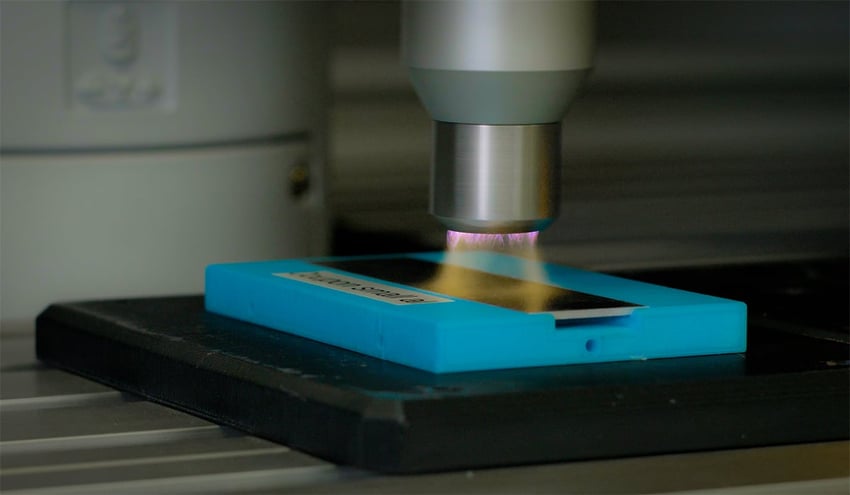

To ensure the surface is clean enough for the coating to adhere to, a simple and quick contact angle measurement before and after each cleaning and treatment step will allow you to see how close the surface is to being ready for coating. Contact angles directly measure surface energy and can detect microscopic residues that will cause the coating to dewet.

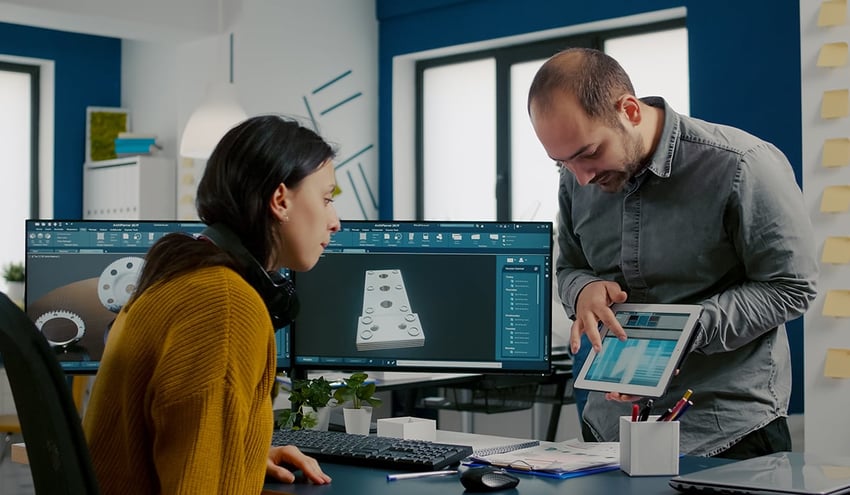

Rethink your adhesion manufacturing processes with Surface Intelligence.

Contact angles work by looking at the behavior of a drop of liquid on a prepared surface. If the drop beads up (like oil on an oleophobic coating), it indicates the surface has low energy and is not chemically reactive in a way that will promote adhesion to the coating. You can measure the angles made by how large or low the drop is on the surface because the liquid has a high resolution regarding sensitivity to the top few molecular layers of the material. These angles can offer great insight into what might not have been cleaned off a surface or if the treatment was strong enough to create a reactive surface, perfect for adhesion.

It’s also extremely important to control oleophobic substances being applied to certain components of a larger assembly because these coatings can be contaminants in their own right if they are found on a surface they are not meant to be on. Measuring contact angles on all surfaces at strategic points throughout production processes is the best defense against surface quality drifting out of spec for any reason.

Ensuring the Durability and Longevity of Oleophobic Coatings

For manufacturers applying these coatings, it is vitally important to say, with authority, that the coatings will endure for the length of time the rest of the device remains operational.

Manufacturers are looking for a reliable way to monitor coating durability and reasonably and verifiably assure their customers that they will not have to resort to aftermarket oleophobic coatings due to wear through typical use. Also, we all know that consumers who are unsatisfied with their new tech are among the most vocal on the internet.

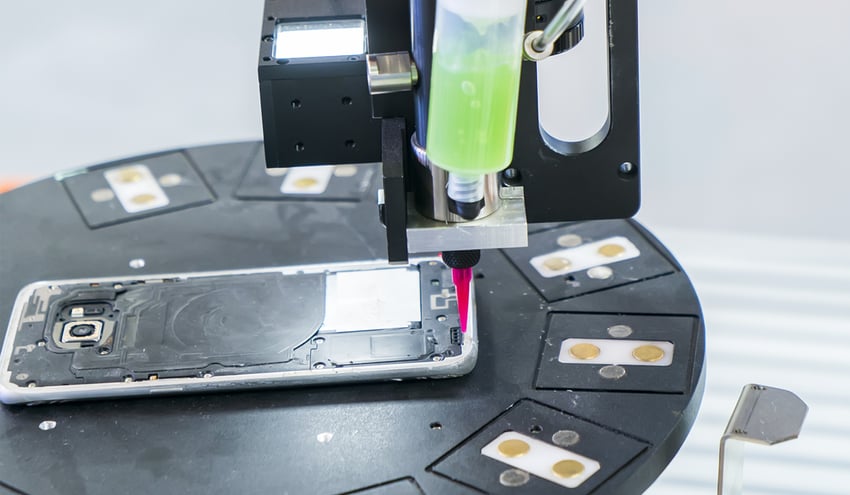

Many smart devices these days are equipped with touchscreens, from watches to thermostats, but none come into contact with more skin more frequently (as well as other environmental oils and residues) than the phones we hold in our pockets.

Again, it’s important to realize that these oleophobic coatings do not keep oils like fingerprints from getting on surfaces; they keep them from staying on the surfaces. They make them “easy-clean,” “smudge-free,” and “streak-free” since they can be easily wiped without a cleaning solution or other cleansing agent.

There are not many good ways to test and monitor the life cycle of an oleophobic coating available to manufacturers. Even though most screens are mostly flat, there are curved edges that can be difficult to test on.

That’s why the contact angle measurement technique is useful when assessing the cleanliness of a surface before coating. It is an elegant and simple solution to test the coating for uniform application and durability under various conditions. There are contact angle measurement systems that can inspect real components directly within the production process, so samples don’t need to be wasted, and manufacturers can conduct 100% verification on all products. There are automated systems available for industries that require a high-rate inspection as they produce hundreds or thousands of units at a time.

It’s fast. It’s accurate. It’s non-destructive. It’s the Automated Surface Analyst.

With the right deposition technique and measurement vantage point (whether the drop is looked at from the top or the side when its angle is being measured), the liquid drop can easily be deployed onto curved surfaces. It’s also possible to map out the entirety of the coated surface to get a sense of the uniformity of the application. With the right contact angle system, this can be done easily and quickly.

The contact angle on an oleophobic surface should be quite high (sometimes >90°). As the coated device is used—rubbed with fingers swiping back and forth, held next to a person’s cheek for hours, taken in and out of pants pockets—the coating will inevitably degrade to some degree. But how much? This is what manufacturers need to know and be able to convey to their customers.

Tracking the lifecycle of the coating through the changing behavior of the liquid drop on the surface offers a quantitative, repeatable quality assurance process that can accurately predict how long these coatings will remain intact.

To learn more about implementing an inspection process to ensure coatings' life will keep up with your products, download our eBook, The Future of Manufacturing, to increase your production intelligence and build more accuracy in your surface preparation and coating process. Get your copy today.

.jpg?width=850&height=495&name=metal-brazing-copper-component%20(reduced).jpg)