Key Takeaways

- PTFE (polytetrafluoroethylene) is widely used in medical devices for its lubricity, chemical resistance, and biocompatibility, but these same traits make it extremely difficult to bond.

- Chemical etching transforms PTFE from an inert, low-energy surface into a reactive, high-energy surface capable of forming durable bonds.

- Water Contact Angle (WCA) measurement is the most reliable method to verify etch quality and ensure repeatable adhesion.

- Surface verification tools like BConnect allow manufacturers to quantify surface quality, control process variation, and maintain predictable adhesion outcomes.

- Proper storage and re-verification of etched PTFE are essential to preserve bondability prior to assembly.

PTFE: A Material That’s Both Ideal and Impossible

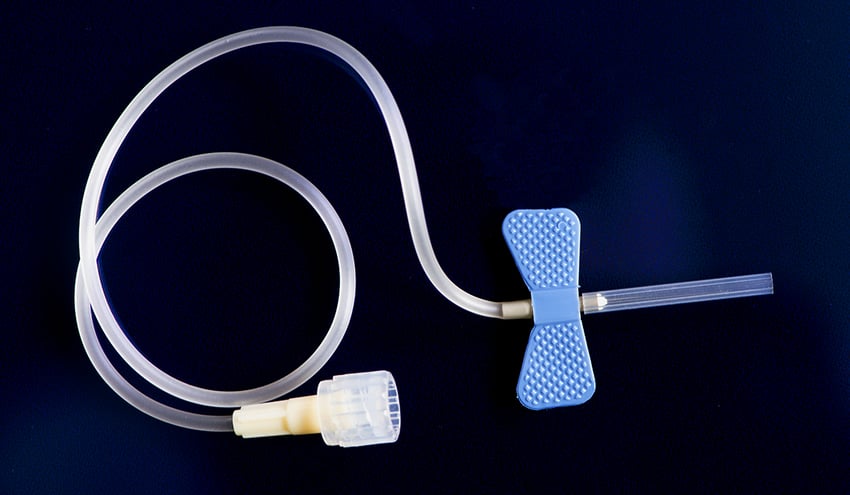

Polytetrafluoroethylene, or PTFE, is an essential material across modern manufacturing, but nowhere is its performance more critical than in the medical device industry. Known for its low friction coefficient, chemical inertness, and purity, PTFE is used in everything from catheter linings and tubing to seals, connectors, and insulation.Its slick, non-reactive surface allows surgical tools and instruments to move freely and prevents contamination or bacterial buildup, key advantages in healthcare applications. However, these same molecular characteristics that make PTFE so valuable also make it notoriously difficult to bond, coat, or print.

So how do manufacturers ensure reliable adhesion to a material that’s literally designed to resist it?

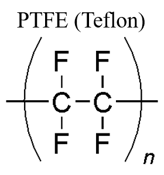

Why PTFE Resists Bonding

PTFE’s carbon-fluorine (C–F) bonds are among the strongest in chemistry. This structure creates a surface that is:

- Chemically inert, resisting reaction with adhesives or coatings

- Low in surface energy, meaning liquids bead up instead of spreading out

- Highly lubricious, limiting mechanical or molecular grip

In short, nothing sticks to it—and that’s the problem. To enable adhesion, PTFE must first be chemically modified so the top few molecular layers become reactive and able to bond with other materials.

Chemical Etching: Transforming an Inert Surface into a Bondable One

The most proven and controlled way to activate PTFE’s surface is through chemical etching. During this process, PTFE is immersed in a sodium-based etchant (such as Tetra-Etch®) that selectively breaks some of the carbon-fluorine bonds.

This reaction removes fluorine atoms and leaves behind electron-deficient carbon sites, which readily bond with oxygen, water vapor, and hydrogen from the surrounding air. The result: a reactive, high-energy surface that can chemically interact with adhesives, coatings, or overmolding materials.

Importantly, etching only affects the top few molecular layers, preserving the mechanical integrity and biocompatibility that make PTFE ideal for medical use.

Tip from a Surface Scientist:

Color changes in etched PTFE, typically a brown or tan tint, don’t indicate bondability. Only quantitative surface analysis, such as water contact angle measurement, can confirm that the etch achieved the right level of reactivity.

- Dr. Giles Dillingham, Founder and Chief Scientist, Brighton Science

Verifying Etch Quality with Water Contact Angle Measurement

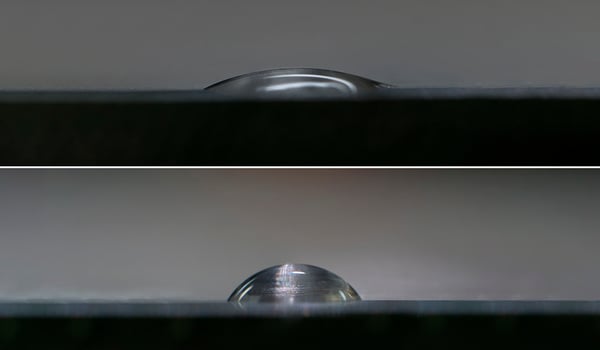

After etching, visual inspection alone isn’t enough. The true measure of surface readiness lies in its interaction with water.

A Water Contact Angle (WCA) test uses a precise droplet of ultra-pure water placed on the PTFE surface. A camera or optical sensor measures the angle between the droplet’s edge and the surface.

- High contact angle (e.g., 95°) → indicates a low-energy, unetched surface (water beads up).

- Low contact angle (e.g., < 40°) → indicates a high-energy, well-etched surface (water spreads out).

This test quantifies surface wettability, directly correlating with the PTFE’s readiness to bond. By establishing a target WCA range, engineers can confirm whether each batch of etched material meets the necessary reactivity threshold before moving forward in production.

Tip from a Surface Scientist:

Measure WCA both before and after etching to understand how your process changes the surface. This baseline-to-final comparison is the foundation of a predictable adhesion specification, a measurable surface standard tied directly to performance outcomes.

Building a Predictable Bonding Process

Integrating surface data into the manufacturing workflow transforms bonding from an art into a science.

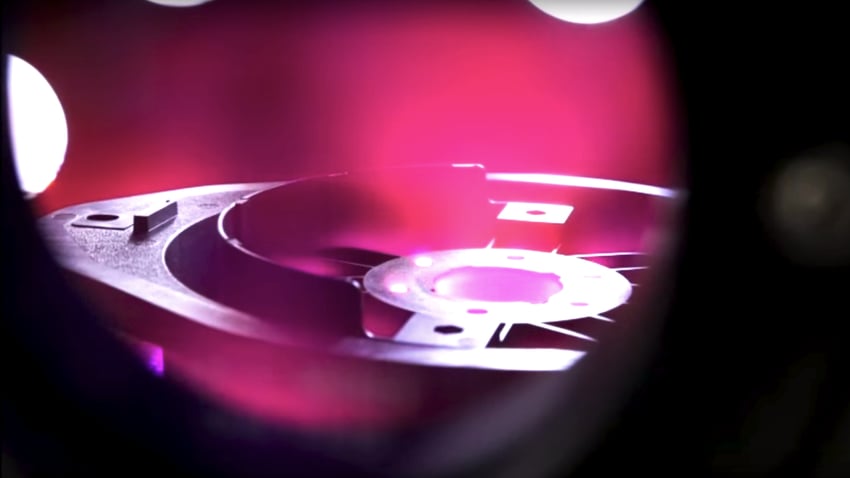

Using a verification platform like BConnect, teams can:

- Quantify each surface’s contact angle and energy level in real time

- Verify that etching, cleaning, or handling steps achieved the desired result

- Control variation by linking surface data to process parameters

- Document compliance for regulatory traceability in medical device manufacturing

When surface conditions are defined and measurable, bonding PTFE becomes a repeatable, auditable process, not a trial-and-error step that jeopardizes product reliability.

Maintaining Etch Quality: Storage and Handling Best Practices

Once PTFE has been chemically etched, its newly reactive surface becomes highly sensitive to contamination. Any exposure to air, moisture, or handling can alter its chemistry and reduce bondability.

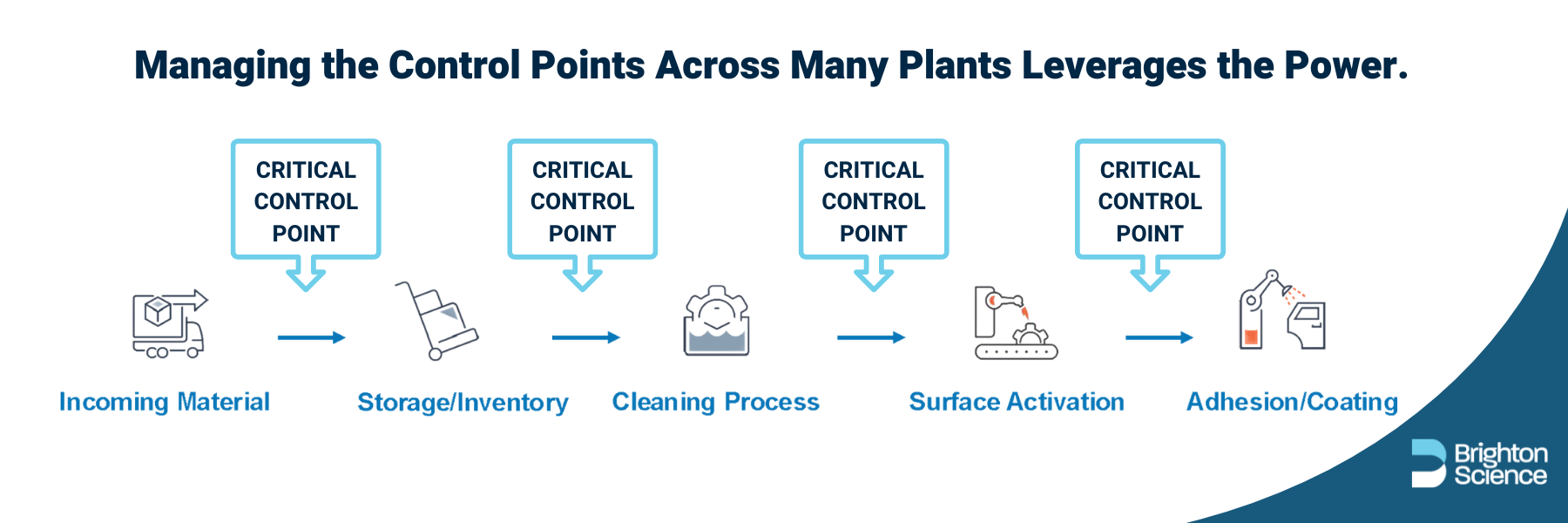

To maintain quality, treat storage and inventory as a Critical Control Point (CCP) in your workflow:

- Store etched PTFE in sealed, UV-blocking bags or its original resealable packaging.

- Avoid unnecessary air exposure and handle only in clean environments.

- Re-measure the water contact angle before use to ensure surface energy hasn’t degraded.

Even small changes in storage conditions can shift surface energy and lead to unpredictable bonding failures later.

Tip from a Surface Scientist:

Think of etched PTFE like freshly prepared sterile equipment. It’s chemically “clean” and eager to react. Protect it from everything that could contaminate or deactivate its surface before bonding.

Bringing It All Together

PTFE’s unique combination of inertness and strength makes it indispensable in medical device manufacturing, but achieving strong adhesion requires both chemical activation and quantitative verification.

By using chemical etching to raise surface energy and water contact angle testing to confirm consistency, manufacturers can create a predictable, validated bonding process that ensures long-term performance.

Bonding PTFE isn’t impossible, it’s a controlled chemistry problem. With the right surface treatment, measurement, and verification tools, you can ensure every device, seal, or assembly built with PTFE performs predictably and reliably.

To explore how Surface Intelligence can transform your process control, download our free guide:

Or, learn how BConnect integrates surface data into your quality workflow for real-time verification and regulatory traceability. Discover BConnect

Frequently Asked Questions

Q1: Why can’t PTFE be bonded without etching?

Because PTFE’s carbon-fluorine bonds make it chemically inert and extremely low in surface energy. Without modification, adhesives cannot form chemical or mechanical bonds with it.

Q2: What is the best way to verify that PTFE has been properly etched?

The most reliable method is water contact angle measurement, which quantifies surface energy. Lower contact angles indicate higher reactivity and stronger bond potential.

Q3: How long does etched PTFE remain bondable?

It depends on storage conditions. Exposure to air and moisture gradually reduces surface reactivity. Store etched PTFE in sealed, UV-blocking packaging and verify its contact angle before bonding.

Q4: Are there alternatives to chemical etching?

Some plasma and mechanical treatments exist but rarely achieve the same uniformity and depth of chemical activation as sodium etching. Chemical etching remains the most proven and repeatable approach.

Q5: Can surface verification be automated?

Yes. Platforms like BConnect allow automated contact angle measurement, data capture, and process monitoring, ensuring each batch meets bonding specifications.