The manufacturing industry has undergone unprecedented challenges in recent years, necessitating a fundamental re-evaluation of business continuity strategies. While economic downturns have historically presented obstacles, the complexities of today’s globalized and interconnected business environment demand a more proactive and resilient approach.

Manufacturers are now confronted with a "new normal" characterized by increased volatility, supply chain disruptions, and rapidly evolving customer demands. To thrive in this landscape, organizations must prioritize developing and implementing robust business continuity plans that address potential risks and ensure operational resilience.

As organizations navigate this new landscape, it is essential to identify best practices for ensuring resilience, mitigating risks, and capitalizing on emerging opportunities.

What Manufacturers Need to Do to Ensure Business Continuity

It’s crucial to our world’s financial infrastructure that we figure out how to move forward, not with business as usual but with an eye to the future molded by our extraordinary times. What’s more, we need to absorb the lessons of how to react to unforeseen events and remain flexible and viable simultaneously.

There are often costs to flexibility, but the price manufacturers will pay if they are not able to adapt quickly and make choices based on the best available data will be much more severe. They may not be a setback from which they can recover.

To give some insight into the ways manufacturing has changed and the challenges and questions that have come along with that change, we’ve gathered thoughtful and useful articles from various publications that speak directly to this moment. Manufacturers who are working through big institutional changes or major workforce transitions or those who want to position themselves to navigate future upheavals better will gain a lot of actionable information and wisdom from these articles.

Will New Hand Washing Practices Cause Problems for Manufacturing?

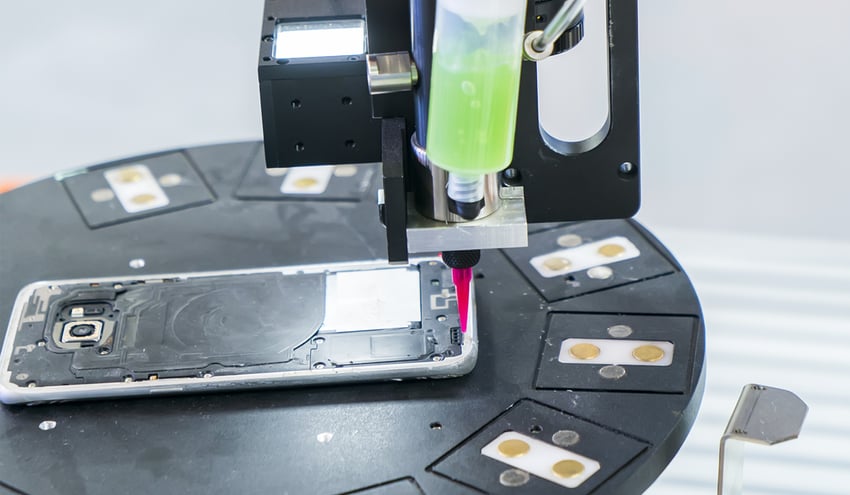

Many changes have already been implemented in the last few months to help manufacturing facilities run smoothly and safely. Even with a vaccine in our midst, practices such as frequent hand washing, hand and surface disinfection, and various forms of personal protective equipment are being worn while technicians complete their work.

These changes raise questions about how these new variables might affect the manufacturing process. Introducing new substances into a manufacturing setting can have unexpected effects on outcomes, and it’s very important to understand the impact of something like hand sanitizer being transferred from someone’s hand onto a surface that will need to have paint, ink, or glue applied.

Struggling with adhesion failures? Been there. Solved that.

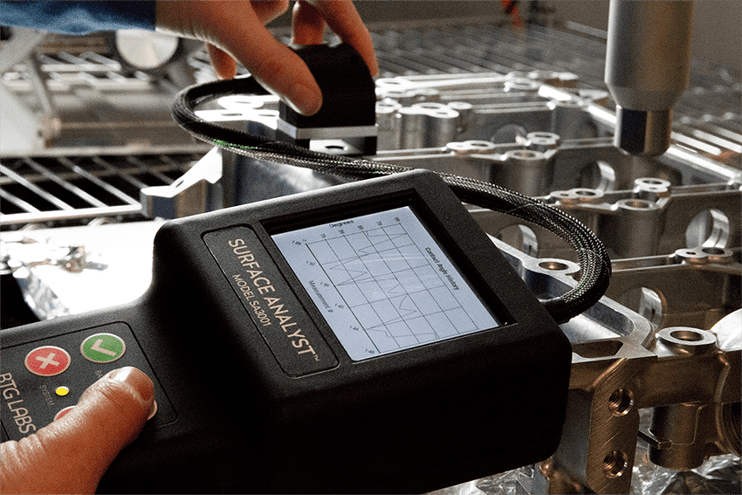

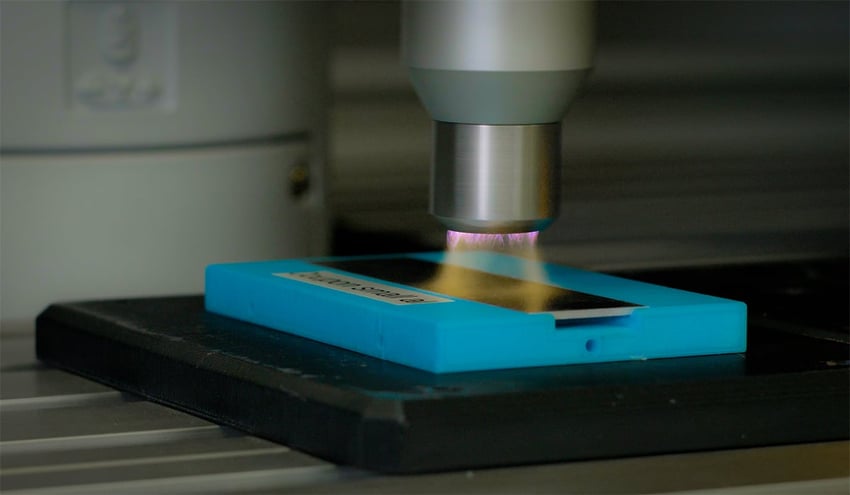

To understand this relationship between adhesion strength and some of the substances manufacturers have had to bring into their facilities in higher volume, experts at Brighton Science conducted a study to examine how easily molecules of these materials can transfer to surfaces and what that might mean for part cleaning and adhesion processes.

“We began by flame-treating chrome-plated steel coupons, or ferrotype plates, that we would be subjecting to unwashed, sanitized, and washed hands, respectively. To get a picture of what was on the surface of each sample, we used a surface analysis method called reflection absorption infrared spectroscopy (RAIRS), which can detect substances on surfaces as thin as a few molecules. Analysis done using RAIRS is expressed in spectra with peaks at certain wavelengths indicating the presence of particular substances.”

Read the rest of the article from Brighton Science here to find out the results of the test.

Manufacturing operations face key disadvantages when returning employees to work

Manufacturers are positioned in some key ways to overcome safety concerns since that is a daily interest for companies that often utilize massive machinery that could easily harm workers in the plant. But there are also many obstacles and vulnerabilities manufacturing companies face that aren’t as prevalent in other industries that are also deeply affected by the pandemic. Starting back up, hiring back staff, or continuing with new restraints in place while maintaining high productivity, product quality, and a new level of employee safety rely on an interrelated web of decisions that must be made, which can lead to more difficult choices for manufacturers in the near future.

“Social distancing is one practice that may be difficult to implement at a manufacturing operation. Often, the layout of a plant is generations-old and revolves around maximizing efficiency. As a result, these layouts can be very expensive and complicated to change. This situation can cause some competing concerns, though...it’s important to place both objectives on the table and realize that, in many cases, they aren’t mutually exclusive.”

Read the rest of the article from Insurance Business Magazine here.

Manufacturers Shift to PPE Production to Fight COVID-19 Pandemic

In the second and third quarters of 2020, many manufacturers pivoted from their normal products to begin building devices and items that there was suddenly a much higher need for. This had the double-barreled effect of helping meet the demand for things like personal protective equipment, virus test kits, and even household items like toilet paper while also allowing manufacturers to retain their workers and utilize their factories during a time when the market for their normal products may have shrunk.

Taking a look at how manufacturers were able to flex their staff and facilities in this way can offer a lot of insight into similar versatility, and quick maneuvering other manufacturers may have to do in the future. The need for particular medical devices is not diminishing soon, and manufacturers may need to continue to expand their capabilities.

“In late March, Ford Motor Co. and General Motors Corp. shut down car production and redeployed their Detroit factories and workers to produce ventilators. Ford was expected to achieve a production level of about 1,500 ventilators by the end of May. GM brought its first group of 100 project workers into training in early April and is capable of producing 10,000 units per month.”

Manufacturing In An Age Of Uncertainty

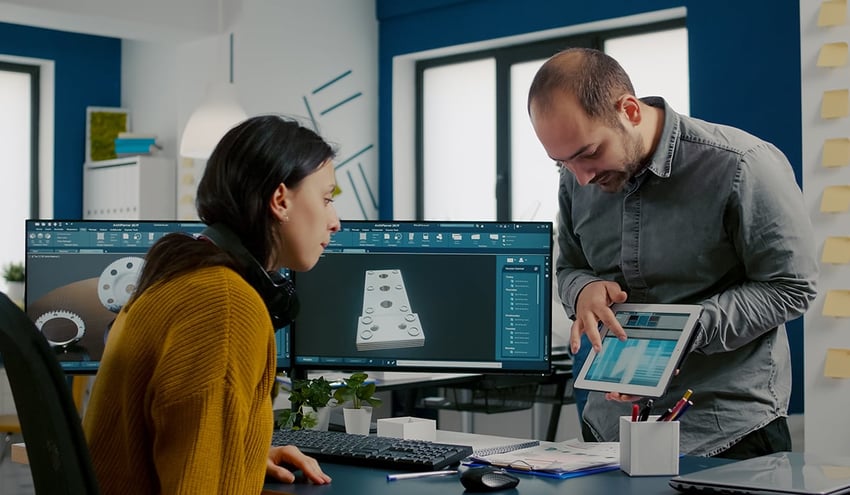

The only true way to combat uncertainty is to gather as much predictive data as possible and make thoughtful decisions based on those analytics. Having quantitative facts to rely on makes communication between all departments, vendors, and teams much easier. This coordination is vital to business continuity; this especially includes teams that have had to go entirely, or even partially, remote.

Getting everyone on the same page means implementing more transparency and more analytical tools than manufacturers might be used to. But the return on these investments will mean that leaner teams can be more agile and responsive - exactly what manufacturers need to be during a pandemic and beyond.

“A recent report from McKinsey & Company highlights three core operational areas that manufacturers need to focus on regarding plant operations in response to the coronavirus crisis. These include protecting the workforce with proper social distancing measures, managing risks to ensure business continuity, and finding new ways to drive productivity even with large parts of the workforce working remotely.”

Back-to-Work Protocol for Manufacturers Post-COVID-19

The most obvious change that manufacturers will have to contend with is the changes that are occurring as a direct result of being in the middle of a global health crisis. There are a lot of new regulations from local and federal governments that need to be complied with and discussed to make sure employees understand what they are and what the implications are for their job.

This is a potentially fraught territory, but there is a lot of guidance available to help figure out the best ways of implementing new protocols and health guidelines. These safety regulations are a starting point for how we can all help each other stay healthy and able to do our jobs.

“Making the matter more difficult is a large number of federal, state, and local regulatory bodies responsible for imposing and enforcing these laws and declarations. This is especially problematic for multistate employers who have to deal with wildly varying restrictive environments. While some states seem to be rushing to reduce their restrictions, others are making little or no change.”

Managing the Unanticipated Risk: Lessons from the Pandemic

Manufacturers are in need of a new business continuity plan because the risks and opportunities that have presented themselves this year were almost impossible to plan for. But they can be clearly seen now, and they must be accounted for in future risk management plans.

There is guidance offered in ISO 9001:2015 for what actions manufacturers can take to incorporate our current moment into their risk and opportunity management plan. The upheaval we’re all going through can no longer be classified as “an unknown,” so we can use this experience to recognize gaps in our quality management systems and increase the collective organizational knowledge around what needs to be done during a pandemic or any disruption of comparable scale.

There is guidance offered in ISO 9001:2015 for what actions manufacturers can take to incorporate our current moment into their risk and opportunity management plan. The upheaval we’re all going through can no longer be classified as “an unknown,” so we can use this experience to recognize gaps in our quality management systems and increase the collective organizational knowledge around what needs to be done during a pandemic or any disruption of comparable scale.

“Now that the pandemic has occurred, organizations must take action to ensure that current actions are effective and, wherever possible, they are avoided in the future. When considering how the requirements in ISO 9001:2015 can help manage unanticipated risks such as the pandemic, there are several clauses that an organization can focus on to assist them.”

The pandemic has changed many things, both temporarily and permanently. The reality for manufacturers is that they need to adapt, remain flexible, find the opportunity in the emergency, and look for ways to adopt new technologies and processes that the need for has become much more clear in the past several months.

To learn more about how manufacturers can find the path to resilient cleaning and adhesion processes through predictive analytics, download our free eBook "The Future of Manufacturing: A Guide to Intelligent Adhesive Bonding Technologies & Methodologies."

.jpg?width=850&height=495&name=metal-brazing-copper-component%20(reduced).jpg)