As manufacturing becomes more complex and the globalization of supply chains increases, the need for a Surface Intelligence Center of Excellence grows. Such a center would compile data, training, and best practices from across the business to identify areas where further efficiency and quality improvements could be made in materials and processes. The benefits of such a center are numerous, and this initiative must receive the attention it deserves to keep up with the complexity of manufacturing.

What is a Center of Manufacturing Excellence?

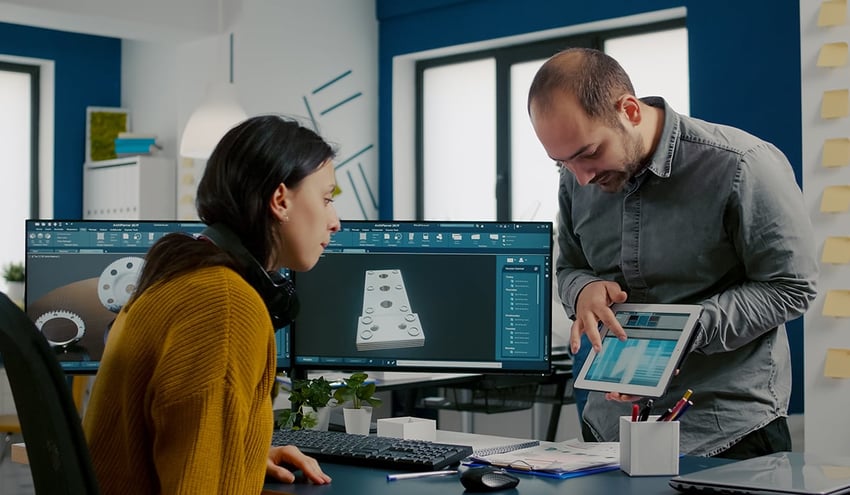

In general, a Center of Manufacturing Excellence is a centralized and highly coordinated place, team, or entity within an organization where employees can seek out training, education, research, and best practices about manufacturing. This centralized resource gives the company valuable insight into its processes and what other companies in the same industry are doing with their manufacturing operations. If done correctly, the center becomes integrated into the company culture and is a consistent practice across the organization.

Additionally, by creating these standards and procedures for how things are done at a company, they can streamline their production processes efficiently and effectively.

Why is it Important That Companies Add Surface Intelligence and Materials and Processes to a Center of Excellence?

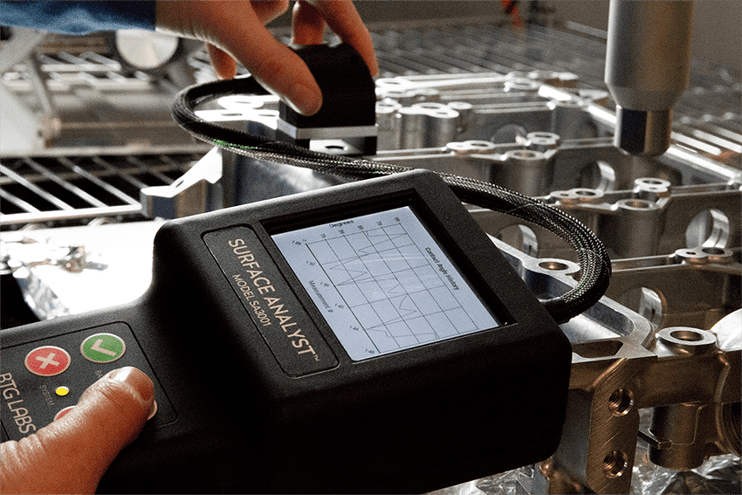

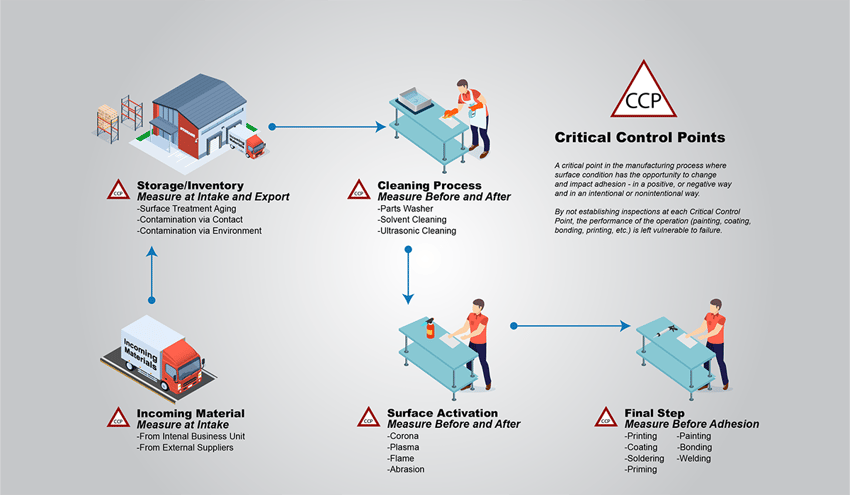

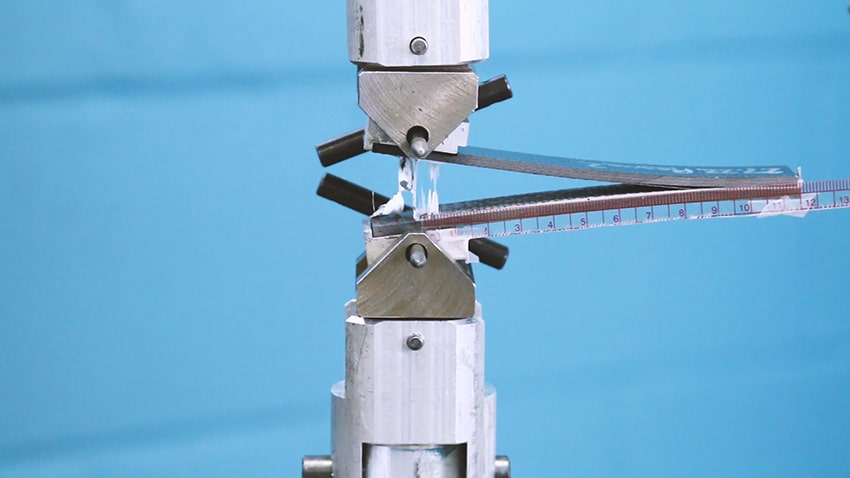

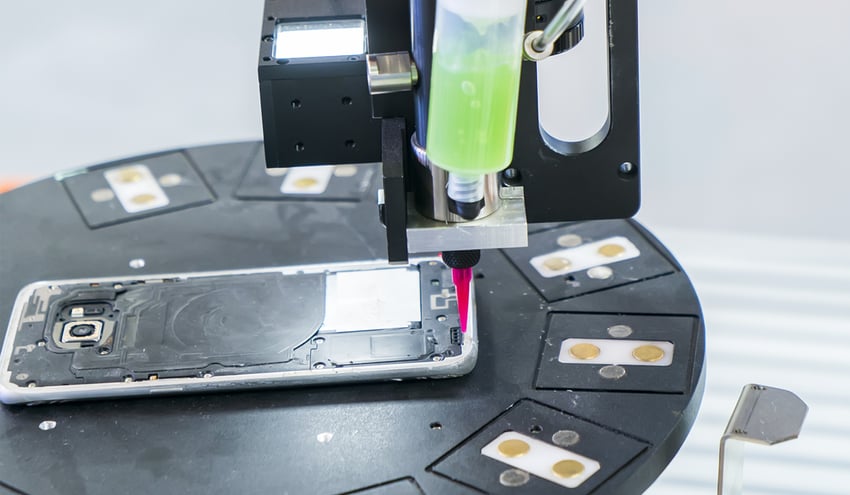

Surface Intelligence is the combination of the appropriate diagnostic tools and surface chemistry expertise that allows businesses to have visibility and insight into real-life adhesion, manufacturing, product development, and supply chain challenges. This unique combination results in reliable manufacturing methods and, in turn, better products and results.

When it comes to producing complex and high-quality products, some of the largest companies in the world have teams dedicated to evaluating the quality and assembly of materials, but the majority of the manufacturing base does not have this ability. Instead, they often rely on outside vendors like adhesive vendors to solve adhesion and coating problems. When there is a lack of knowledge regarding surface science and materials and processes, the organization opens itself up to a large area of risk. Relying on adhesion, coating, or assembly information provided by vendors can create this opportunity of risk because the material systems and processes are not being viewed holistically. In turn, the manufacturer developing the product may not be given the best solution from the vendor to produce the best product possible.

Having access to materials and process expertise is essential for companies that wish to develop high-quality products quickly. The advantages of having this data include taking a product launch from a 12-month development cycle to just a matter of weeks. By having access to Surface Intelligence information on different material types and assemblies, manufacturers can measure and model success, optimize designs based on specific performance characteristics like weight or color, and avoid issues with reliability or performance over time by pre-approving the materials and assembly methods used. Suppose you do not have access to this material science expertise yourself. In that case, you need to enlist the services of an experienced manufacturer like Brighton Science which has these capabilities at its disposal.

Rethink your adhesion manufacturing processes with Surface Intelligence.

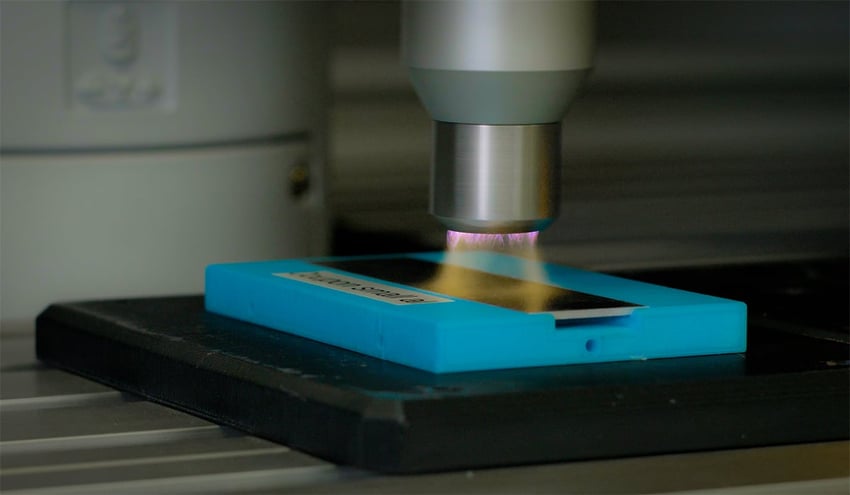

The First Step: A Materials Library

If you have a materials team that qualifies materials, you already have some aspects of the materials library in place. However, the critical missing piece to a successful materials library is the organization of the materials library in such a way that you organize it not only by materials and application (this isn’t the key to success) but also by including surface data. Knowing the surface cleanliness and surface chemistry standards for the materials system is essential. If surface cleanliness and surface chemistry standards exist, they are cursory and often attached to a dyne ink standard. This makes them difficult to deploy to manufacturing. Additionally, businesses often appoint engineers who are already on staff to develop these standards which can open the business up to an additional layer of risk by employing individuals who have not been formally trained in materials science to lead the project.

Alternatively, businesses have the option to work with companies like Brighton Science which specializes in this area and is equipped with materials libraries, years of expertise, and Surface Intelligence data. Having access to this information saves time and energy that would be otherwise spent on developing new materials from scratch. Investing in an internal library of materials is the first step in creating a center of excellence for materials and processes.

The Benefits of a Materials Library

If you're looking to create a materials library, doing so comes with many benefits:

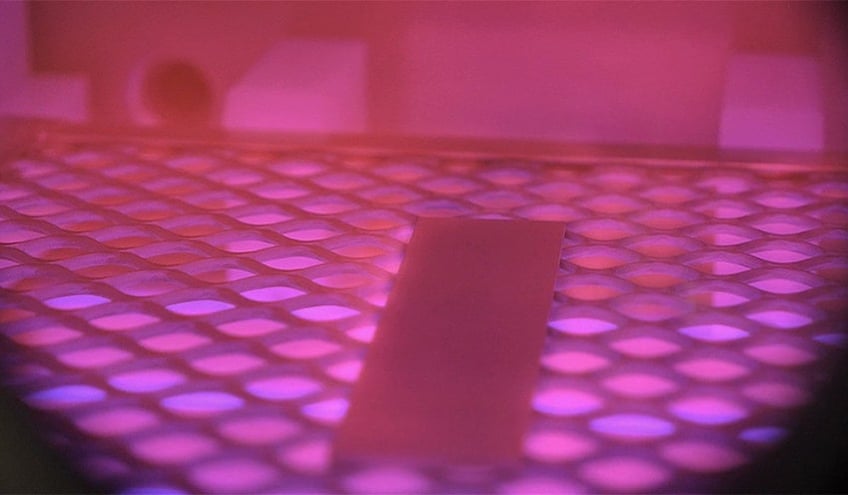

- It builds internal knowledge over time and allows you to benchmark your programs, helping you scale faster and more efficiently.

- Having this extensive materials database means that you can quickly select the materials and assembly methods best suited for your projects and develop a comprehensive manufacturing plan. This material experience minimizes risk and reduces the time it takes to get a product to market, sometimes from six months to six weeks.

- There are fewer risks associated with creating a materials library, as you'll know which materials and assembly methods work well together and which ones don't. This allows you to make informed decisions about your material choices, ensuring that your products meet product specifications.

- The business gains overall expertise and surface quality culture from the center of excellence, and the rate of knowledge development is then accelerated.

To be a top-performing product development organization today, you need to have access to materials experience, and building a materials library is the best place to start. If you are already doing this, include surface quality when creating your surface and assembly recipes. When businesses place an emphasis on surface quality and awareness of Surface Intelligence, it builds a culture of high-quality standards across the board. The result is more freedom to innovate, better products, and more reliable manufacturing.

Brighton Science has developed a center of excellence for manufacturing to tackle these problems, which combines the right people, processes, and technology to address manufacturing assembly issues and build value for companies. A strong understanding of surfaces will help you make better products and avoid risk.

Optimize the power of next-gen connectivity with data & surface intelligence.

Learn how your business can begin the process of building surface science awareness and knowledge in order to build an internal Surface Intelligence Center of Excellence by downloading the eBook "The Future of Manufacturing: A Guide to Intelligent Adhesive Bonding Technologies & Methodologies."

.jpg?width=850&height=495&name=metal-brazing-copper-component%20(reduced).jpg)