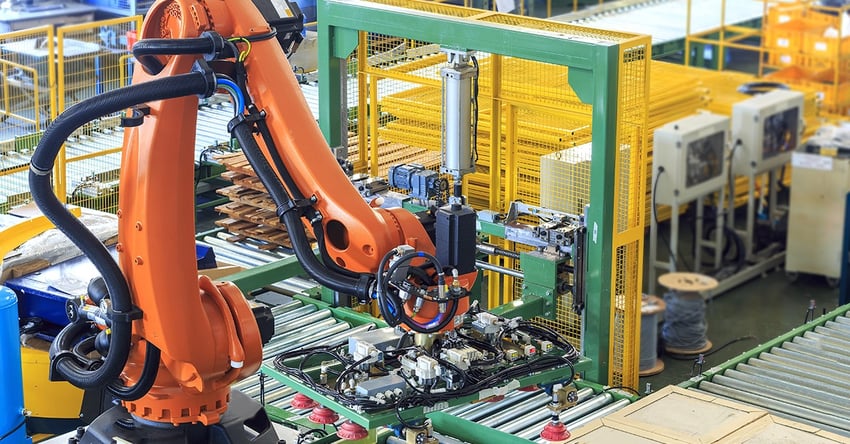

Materials as technology is one of the most important fields in developmental science. As new materials are created and perfected, they proliferate and quickly spread to manufacturing centers around the world, spurring innovative product design. The rapid development of ceramic, sustainable materials, composite, and nanomaterials has opened new opportunities for the innovation of products for virtually every application and industry. The challenge now is how product designers can take advantage of these new materials and have confidence they will perform as expected.

What’s needed is a way for teams to utilize new technology and methodologies that reduce risk and safely speed up the process. Or, as the entrepreneur’s mantra recommends, to “fail early and fail often” so that inefficient and unreliable options can be quickly eliminated in favor of more promising paths that will lead to success sooner.

The solution requires surface science experience and tools to help designers evaluate new materials and bonding methods to determine which materials will perform better in high-volume manufacturing while achieving product performance and cost goals. The growing consumer demand for products with greater longevity, efficiency, and performance is driving companies to explore these new materials.

Increased competition and an urgent need to deliver “the next best thing” are driving manufacturers to look for ways to replace traditional materials such as steel, aluminum, wood, and conventional plastics with something stronger, lighter, and more cost-efficient. For example, MIT has recently announced that a team of its engineers has developed a new composite material made from cellulose nanocrystals that holds promise for a new category of sustainable plastics. According to MIT researchers, this new plant-derived composite is stronger and tougher than some types of bone and harder than typical aluminum alloys.

Rethink your adhesion manufacturing processes with Surface Intelligence.

This kind of expertise is in high demand and hard to come by. Companies that don’t have that depth of internal knowledge will need to partner with experts who can provide it. With access to technical support such as that, manufacturers will be free to explore all sorts of innovative avenues.

A good example of that comes from golf club maker TaylorMade Golf Company and its revolutionary Carbonwood™ material. This advanced composite was developed by an internal engineering team using carbon, which is lighter and less dense than titanium, providing better energy transfer – ideal for a superior golf club face. The team of engineers partnered with chemists to develop an all-new polyurethane material specifically for carbon drivers. They learned a lot about bonding and adhesives during the project, becoming experts on making things stick together and using advanced industrial epoxy together with established bonding best practices. The result was their highly successful new line of drivers, appropriately named Stealth, after the secrecy used to protect the project.

How Outside Expertise Can Make a Difference

To succeed, design teams must be willing to think differently about every aspect of a new product. How do new substrates, coatings, adhesives, and processes affect overall quality, reliability, and performance? What design constraints exist, and how do you overcome them? Sometimes, it takes a different perspective from an outside resource to change the product development dynamic.

For example, nature can be an excellent source of inspiration. Biomimicry – designing and manufacturing materials and products based on biological entities and processes – can provide valuable insight into the best solution. A gecko’s skin, for instance, exhibits a high contact angle for water droplets, suggesting ways to develop a more water-repellent membrane. Partnering with an outside firm that utilizes biomimicry as one of the tools in their toolbox is just one way to gain fresh perspectives on product design options. A partner with experience with a wide range of materials, assembly methods, and manufacturing processes and a deep understanding of chemistry can help you do new things with new materials.

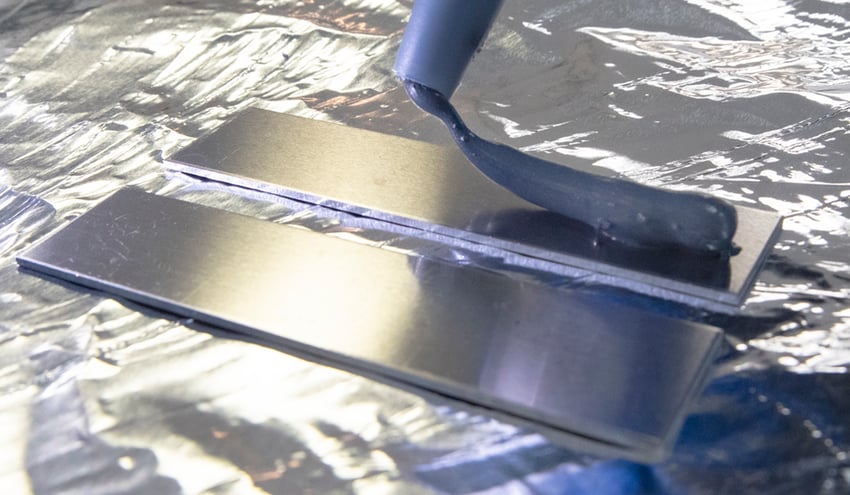

Adhesion is More Than Just Adhesive Materials

Most manufacturers work with adhesion in some fashion, whether it’s assembling components together or painting a surface. Many companies that work with paints and sealants don’t even think of them as materials with adhesive properties. They may even be unfamiliar with the chemical properties behind bonding and what helps ensure optimal adhesion for a coating. A growing number of manufacturers are turning to adhesive fasteners to replace mechanical ones and reduce the number of components that go into a product. However, to adequately understand the effectiveness of the mechanical grip holding two components together, it’s important to understand the chemical grip that makes it possible.

Understanding and controlling these underlying characteristics can give designers the confidence to work with new materials and processes – to reimagine what’s possible. Sometimes, it means rethinking what can be done with existing materials, such as metals and alloys. For example, Elon Musk and the design team at Tesla developed a new aluminum alloy that needs no further heat treatment after casting to avoid deformation and maintain structural integrity in Tesla’s automobile structure. Listen to the full interview here.

Optimize the power of next-gen connectivity with data & surface intelligence.

We are living in perhaps the greatest age of material and technological advancement. Ground-breaking developments are happening at dizzying speed in metallurgy, composites, and production processes, enabling the creation of exciting new shapes and variations in structure that could only be dreamed of until recently. There has never been a more perfect time to consider new ways to think about and build new products. Any company with imagination and the desire to adopt innovative technologies and data will gain the confidence necessary to work with new materials and will be poised to change the world.

Read the eBook to learn how surface intelligence equips manufacturers with the data needed to confidently innovate new products and processes: The Advanced Guide to Transforming Product Development Through Surface Intelligence Data & Technology.