This paper demonstrates how contact angle is an extremely sensitive and rapid method to check for surface cleanliness and consistency for aircraft repair.

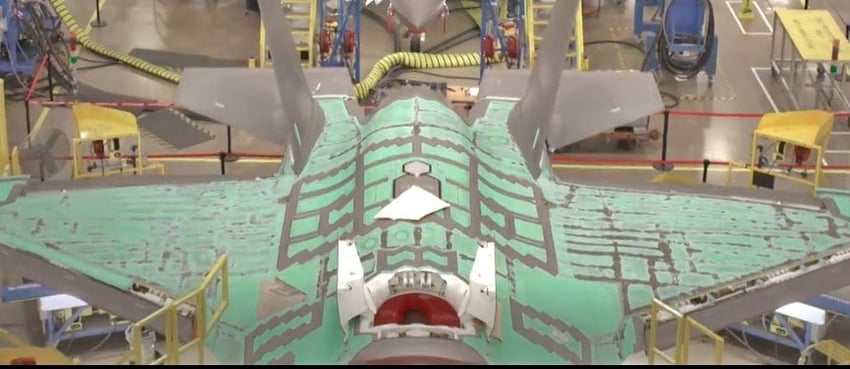

Adhesive bonding processes are increasingly becoming the techniques of choice and/or necessity for many aircraft repair procedures. There are several reasons for this trend. Bonded repairs allow complex-shaped patches to be blended into critical aerodynamic surfaces without loss of performance. They also avoid the necessity of introducing the stress concentrations that accompany the holes necessary for mechanical fasteners.

Adhesive bonding processes are increasingly becoming the techniques of choice and/or necessity for many aircraft repair procedures. There are several reasons for this trend. Bonded repairs allow complex-shaped patches to be blended into critical aerodynamic surfaces without loss of performance. They also avoid the necessity of introducing the stress concentrations that accompany the holes necessary for mechanical fasteners.A major concern with any bonded repair is a dis-bond that can occur at the installation of the doubler or at any time during the service life of the aircraft.

Measurement of the geometry of a liquid drop deposited onto the surface can be done extremely rapidly and form the basis of a sensitive check of surface cleanliness and consistency in a repair depot or in challenging field situations. This paper discusses the use of these rapid wetting measurements for quality assurance of surface treatments for adhesively bonded repairs.

Download the paper: Qualification of Surface Preparation Processes for Bonded Aircraft Repair