In order to ensure successful bonding, coating, printing, painting, laminating or meet cleanliness standards in manufacturing, material surfaces must be manipulated. One such manipulation that gets surfaces ever closer to being ready for adhesion is surface treatment. There are many operations and processes that could be considered treatment, and one could be forgiven for misconstruing terms like treatment and cleaning as meaning the same thing when they really do not. To eliminate confusion, let's define what we mean by treatment.

A surface treatment is any intentional preparation step in an adhesion process that changes the chemistry of the surface in the material system.

Treatments are heavily science-based operations, and common treatment steps could include chemical etching, plasma, corona, flame, laser ablation, and anything else that activates molecular functional groups on the material surface. These functional groups are highly reactive, and once they are created, they are very eager to bond with an adhesive, coating, or another material system.

Rethink your adhesion manufacturing processes with Surface Intelligence.

It is almost always impossible to see with the human eye changes that have occurred on a surface once it has been treated. There might be some change in color or surface geometry, but the crucial molecular changes cannot be inspected or assured without help.

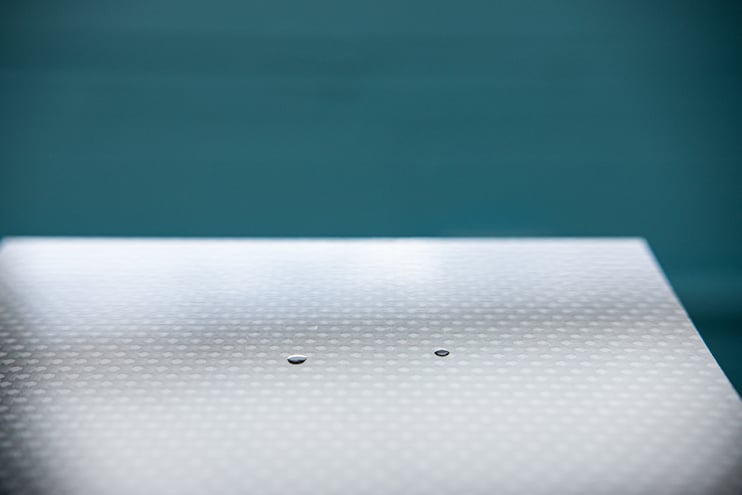

Look at these three samples below; composite, aluminum, and plastic, respectively. Can you tell which side of the material was plasma treated just by looking? The answers can be found at the end of this article, along with the water contact angle measurements for both the treated and untreated sides. See if the water contact angle correlates to your expectations and if it accurately detects the treatments.

-

-

-

Hover message

Hover message

So how can manufacturers be certain that their surfaces are truly treated, and what’s more, how can they be certain that their surfaces have been properly and sufficiently treated?

Always Measure Your Surface Quality

Let’s define surface quality as how ready the surface is for adhesion. Common adhesion processes can be broken down into bonding, coating, printing, painting, and laminating. Treatment gets the surface closer to being more prepared, but if you don’t have an objective, identifiable metric for knowing how much closer -- then you’re flying blind.

Every surface treatment is a Critical Control Point. A Critical Control Point is any part of a manufacturing process where the material surface has the opportunity to change, for better or for worse, intentionally or unintentionally. To control what is happening on the surface and guarantee adhesion success, a surface quality measurement device needs to be employed at each Critical Control Point. A quantitative measurement that is reliable, non-destructive, and fast needs to be taken before and after every treatment operation. If you put a number on the surface quality before the material is chemically etched, grit-blasted, or plasma treated, then you should see that number change when measured afterward. There should be a statistical difference between each number which will give you a clear understanding of how much the surface is being treated.

Get the Most Out of Your Surface Treatments: Measure Surface Quality

To fully ensure treatments are effective, it is crucial that all Critical Control Points are measured and monitored using either an automated or portable inspection device that can operate directly on the production line. The point at which parts and components enter the manufacturing facility and are in storage are often overlooked as Critical Control Points. But the surface quality of incoming materials and what happens to surfaces while in storage can have a radical effect on treatment procedures.

Measuring the surface quality to get a baseline to optimize all subsequent processes makes a massive difference in getting the most out of your treatment equipment and steps. Surfaces can change dramatically in storage due to ambient contamination, how the material parts are stored and how long it has been since they were last manipulated. All of these things affect the precision of treatment parameters and what needs to be done to optimize them and create the most adhesion-ready surface possible.

If these parameters are not dialed in, then it is not only possible to undertreat the surfaces but also to overtreat them. For every treatment operation, there is a sweet spot that creates the kind of surface that meets the adhesion requirements. Going beyond this point can begin to make it impossible for that surface to be bonded to.

For example, when using atmospheric plasma treatment, you can adjust the stand-off height of the nozzle, the speed at which the nozzle moves over the surface, the power level of the treatment and how long the treatment lasts. All of these adjustments impact how the surface comes out on the other side and how ready it is for adhesion. Testing the effectiveness of these parameters by measuring the surface quality makes predicting adhesion success or the ability to meet cleanliness requirements possible.

Handpicked Related Content:

What About Primers?

Primers can be a very effective way to create a highly reactive surface. But manufacturers have to be careful when choosing a primer and knowing what it is actually doing to the material surface.

There are two types of primers available for most applications: barrier primers and coupling agents. Barrier primers are primarily just anti-corrosive coatings that do not improve the chances of adhesion in most production contexts. Coupling primers actually activate the surface when they are applied. Often, manufacturers believe they are using a primer that functions in this way when what they really have is a barrier primer. This difference can make or break an adhesion process.

In the end, producing consistent results requires a scientific approach to adhesion coupled with paying attention to what constitutes optimal treatment processes. Measure and monitor every Critical Control Point, adjust treatment parameters based on the measurement results and be mindful of what processes and substances (such as primers) are being utilized. These will ensure adhesion is controlled and that you get the most out of your treatment operations.

To learn more about making sure the adhesion process for your application is as effective as possible, download this eBook: “Predictable Adhesion in Manufacturing Through Process Verification.”