The Aerospace and Defense industry is booming. In 2024, global aerospace investments were nearly $1.2 trillion, with the United States accounting for nearly $450 billion in aircraft and space systems manufacturing. This rapid expansion is driven by technological advancements and rising demand for faster, safer, and more fuel-efficient aircraft. The growth is expected to continue well into the next decade.

One major trend fueling this growth is the continuous improvement of materials used in aircraft manufacturing. Lightweighting, reducing the weight of components, has become essential. As modern aircraft integrate increasingly complex electronics and systems, lowering overall mass not only improves fuel efficiency but also enhances safety and speed.

New Applications for Advanced Materials

Additive manufacturing (3D printing) is transforming aerospace production by enabling on-demand fabrication of parts with complex geometries. This technology helps reduce inventory needs and material waste, saving time and costs.

- Common aerospace components produced via additive manufacturing include:

- Wall panels

- Air ducts

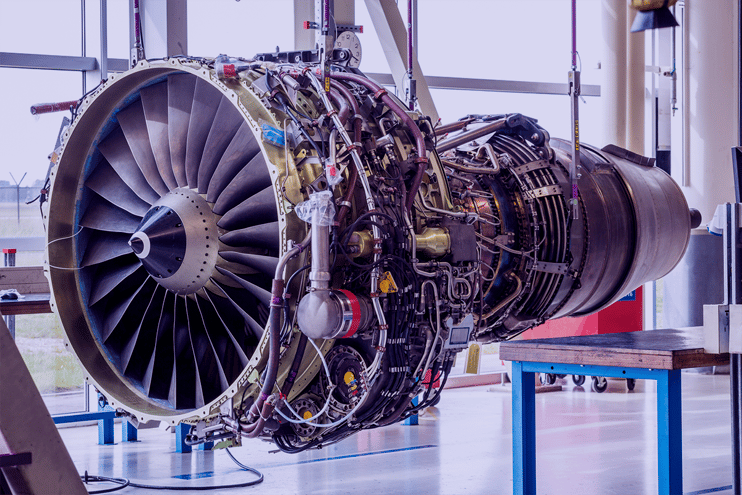

- Engine components

As aerospace applications demand parts with higher strength, lower weight, and more intricate designs, new materials have been developed to meet these challenges. Advanced thermoplastics like PEEK (polyetheretherketone) and PEKK (polyether ketone ketone) have become crucial players in this evolution.

Why Thermoplastics?

Thermoplastics are polymers that soften when heated and harden when cooled without altering their chemical structure. This property allows them to be remolded multiple times, making manufacturing more flexible and cost-effective.

PEEK and PEKK stand out because they combine:

- Exceptional mechanical strength

- High temperature resistance

- Low outgassing (important in aerospace environments)

- Lightweight properties

- Cost efficiency compared to metals like aluminum

These materials offer aerospace manufacturers a winning combination: strength and reliability without the weight of metals.

Challenges in Adhesion and Surface Preparation

Despite their advantages, thermoplastics present unique bonding challenges. Traditional surface preparation methods used on metals—such as abrasion or simple cleaning—do not work effectively on polymers. This is due to their lower surface energy, meaning adhesives struggle to bond strongly without specialized treatment.

Adhesion depends on chemical interactions occurring in the top few molecular layers of a material’s surface. Metals like aluminum have high surface energy, making them naturally more adhesive-friendly. Polymers have lower surface energy, which requires increasing this energy to achieve strong bonding.

Effective Surface Treatment: Plasma Technology

To increase the surface energy of thermoplastics, plasma treatment is the preferred method. Unlike abrasive techniques, plasma treatment:

- Enhances the polar component of surface energy critical for adhesion

- Does not damage or weaken the material

- Creates a highly reactive surface by bombarding it with energetic atoms, promoting oxidation

However, treatment parameters must be carefully managed. Overexposure can lead to chain scission, where polymer chains break apart, weakening the surface and possibly resulting in poor long-term bond strength despite initial good adhesion. This highlights the importance of precision and monitoring during plasma treatment.

The Importance of Process Monitoring

Maintaining consistent surface quality requires real-time monitoring of the treatment process. Without control, manufacturers risk under- or over-treating surfaces, resulting in weak bonds or damaged materials.

By pairing plasma treatment with surface quality inspection technologies, manufacturers can:

- Verify chemical cleanliness before and after treatment

- Ensure treatment levels are optimized—not too little, not too much

- Build reliable, repeatable adhesion processes that improve product quality and reduce troubleshooting

Conclusion

As aerospace materials evolve, thermoplastics like PEEK and PEKK are becoming vital components of lightweight, high-performance aircraft. However, their unique bonding requirements demand advanced surface treatment methods like plasma technology combined with rigorous process monitoring.

Embracing these innovations enables manufacturers to unlock the full potential of thermoplastics, driving safer, lighter, and more efficient aerospace components into the future.

Ready to take your manufacturing operations to the next level?

Download our e-book, Optimizing Manufacturing for a Competitive Future, and discover practical strategies to drive efficiency, innovation, and long-term success.