Excellent adhesion relies on the manufacturer’s ability to understand and control three distinct yet interrelated elements. In manufacturing, adhesive bonding takes many forms, but the fundamental principles of adhesion are always the same.

Even if the application is metal joint welding, Parylene coating electronic components, implantable medical device coating, inkjet printing on plastic film, adhesion of composites, or automotive painting, the science behind what causes adhesion to occur is static and reliable. The conditions for flawless adhesion may involve different parts, materials, and equipment based on the industry, but the basic standards apply across all manufacturing sectors.

3 Elements That Must be Controlled for Successful Adhesion

1. The composition of the adhesive, coating, ink, or paint

2. The application and curing of the adhesive, coating, ink, or paint

3. The quality of the bond surface

All of these present their own challenges to control, but the first two have been well understood and defined by the suppliers of the adhesives and dispensing equipment. The third element is influenced by the widest array of variables and goes through the most changes without detection.

Let’s break each of these down a little more to understand where failure is typically occurring and what manufacturers can do to solve adhesion problems at the root cause.

Choose the Right Adhesive for the Job

The type of adhesive or coating will vary greatly depending on the application. Epoxy and acrylic adhesives are extremely common when bonding metals and some polymers because of their tensile strength and curing specifications. Medical device coatings need to meet specific standards of lubricity and hydrophobicity. Paints and inks need to fulfill certain aesthetic requirements.

All of these considerations are baked into the decision-making process when the design lab is choosing these components. A lot of research goes into this part of the adhesion process. The suppliers of these products have an extremely in-depth understanding of what goes into the adhesives and coatings. They very capably assist manufacturers with choosing the best option for their application as well as solving issues directly related to their products.

Because all this support exists, when adhesion failure occurs, or even during the development stage, manufacturers look at the adhesive to try to understand what went wrong. In our experience, the problem very rarely lies with the adhesive itself.

Ensure Proper Adhesive Application and Curing

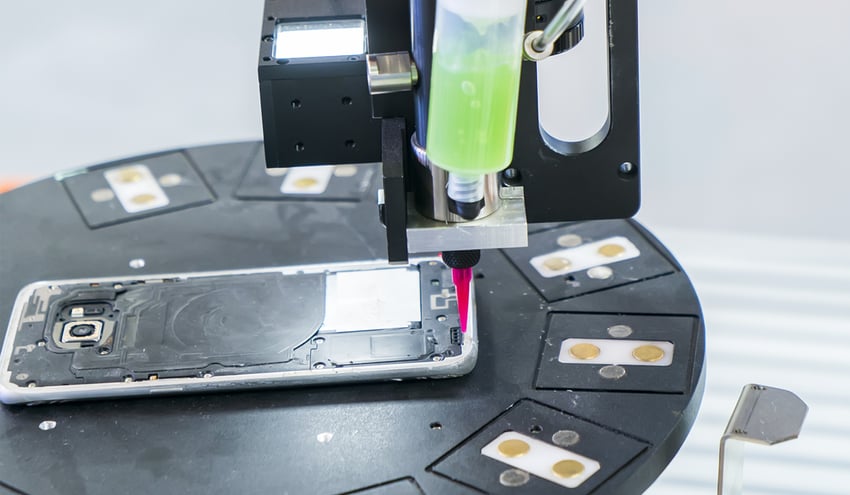

The application and curing process is crucial to get right in order to ensure a strong bond. Regardless of the industry, depositing an adhesive, coating, or paint and then curing that on the surface is well understood. How much heat needs to be applied, the optimal window of time for curing, the amount of adhesive required, and UV curing methods have been developed over long periods of time with lots of experience and research behind decisions made at this step.

There are many specialists who are eager to help in this area, although, much like with adhesive selection, it is very rare for the source of adhesion failure to be found in the application and curing of the adhesive.

Since neither material, adhesive, nor curing inadequacies are the root cause of adhesion problems, it’s important to investigate where in the material system the break is occurring. If the break occurs in the material that is being bonded, coated, or painted, then this is called substrate failure. If the break is within the glue or coating itself, then this is called adhesive failure. If the break is at the interface between the adhesive and the bond surface, this is called cohesive failure.

Being able to recognize these different types of failure gives insight into where manufacturers need to look to get to the root cause of these problems.

Control the Surface, Control the Bond

The most common type of failure occurs at the interface between the material surface and the coating or adhesive (cohesive failure). This is because the surface quality of the material being bonded to is the least understood and the hardest to control.

Rethink your adhesion manufacturing processes with Surface Intelligence.

In order to ensure excellent adhesion, the chemical properties of the top few molecular layers need to be managed. There is so much variability in the interactions that influence the surface state throughout the entirety of the production process, making it very difficult to manage, leading to more adhesion issues.

The goal is to reduce the variability of the surface quality between each part that passes through the manufacturing process. This requires validation of all of the surface preparation steps, monitoring every area where there is a possibility of the surface changing even slightly, and quantitative measurements of surface quality. This will make it clear how far from the required specification each surface has drifted at key points throughout the entire process, including the incoming materials from suppliers.

That seems like a lot, and it does require expertise and equipment most manufacturers haven’t employed because they really haven’t been available until recently. But, being able to create and maintain an adhesion process that produces a quality surface so that the ultimate adhesion application will be successful and predictable is the greatest challenge to manufacturers. This demands looking at the type of failure differently and thinking about the adhesion process holistically so all variables are controlled and managed.

For more information about diagnosing the root cause of adhesion failure and stopping it before it starts, download the eBook “Checklist: Adhesion Failure Root-Cause Analysis for Manufacturers.”