Manufacturing has become increasingly complex with the fusion of technologies that are blurring distinctions between the digital, physical, and biological worlds. Physical products and services have transformed significantly due to enhancements made possible by digital capabilities. New technologies make assets more customized, resilient, and durable, while analytics and data transform their maintenance and efficiency.

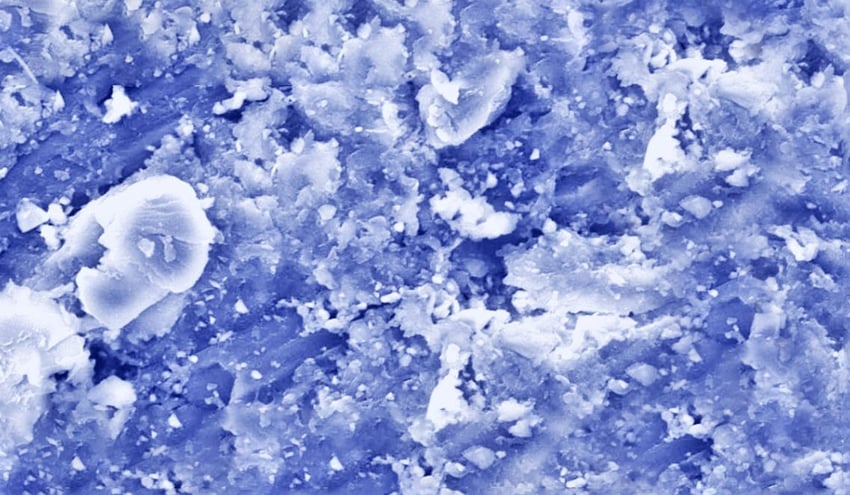

One trend in innovation is focusing on the migration from software back to physical products in the materials, energy, biology, and processing industries. Based on the surfaces of materials used to develop products, these new material systems are thought to be the next wave of innovation.

Rethink your adhesion manufacturing processes with Surface Intelligence.

What Is Surface Chemistry and How Does It Impact Manufacturing?

Surface chemistry is the study of chemical reactions at the surfaces and interfaces between two materials. It is everywhere in industrial settings and is especially prevalent in the designing and building of products in the manufacturing industry.

Surface chemistry is integral in this line of work. If you work with a material to make a part, or if you are gluing, painting, coating, or molding, you are directly dealing with surface chemistry. Surface chemistry defines how easy or difficult it is to manufacture a product, assemble it, the final material properties, performance, and what the finished product will look like. It may surprise you to learn how much a final product depends on surfaces.

When humans interact with materials and surfaces, they are limited to working with the data they can collect with their five senses. They cannot see, feel, or smell molecular or atomic interactions on the surface of a material. This has led to a lack of focus on surface chemistry in manufacturing, affecting the quality of outgoing products.

Businesses must develop a sensitivity to surfaces, for example, having careful consideration for handling products, similar to procedures already in place in the semiconductor industry. Other manufacturing operations need to integrate the same level of consideration for surface chemistry, which is an important aspect of manufacturing.

What Is the Importance of Surface Chemistry?

Manufacturing management is missing out on a significant opportunity to improve their business by actively managing surfaces. This starts with an understanding of surface chemistry and will progress into strategies to solve, prevent, and control surface chemistry issues.

Understanding and managing surface chemistry is essential because it gives manufacturing operations the know-how to handle, store, and effectively process materials. There are specific tools that exist that allow surfaces to be managed. This gives manufacturing management the ability to align incentives across the product life cycle for various KPIs. Doing this will result in a number of benefits to a business, including:

- Faster time to market

- More reliable scaling up of manufacturing

- Better yields and Cpk

- Faster problem solving

- Supply chain alignment

- Increased reliability

- Less risk

The Connection Between Surface Chemistry and New Product Innovation

Understanding surface chemistry will allow businesses to think and innovate in different ways. They can optimize how materials interact with one another, implement new material systems, and investigate new materials for sustainability. It will also allow businesses to advance their surface coating technology and develop new ways of manufacturing, cleaning, joining, and assembling parts.

If businesses begin to use surface management tools and data in their manufacturing, it will create a vast number of new opportunities. It will also give them the confidence, repeatability, and reliability to innovate using new material systems.

A well-known example of this is when SpaceX moved from a carbon-based rocket to a stainless steel-based rocket. This was due to the properties of stainless steel at extreme temperatures (hot and cold) and improved the rocket’s performance while reducing the cost.

The Benefits of Managing Surfaces

Manufacturers can enhance their business in several ways by incorporating the management of surfaces. This would mean aligning the incentives in the organization around what surfaces need to be, how they are handled, and how they must be prepared. These improvements will give the organization significant gains in the performance of creating and manufacturing products.

Case Study: EV Battery Manufacturer

One example of how a manufacturing company improved its production process by integrating surface management comes from an EV battery manufacturer. During a test-pilot program, the battery manufacturer found significant sealing issues that resulted in leaks to safety-critical joints.

By employing surface intelligence, the team could pinpoint contaminants originating throughout the supply chain that negatively impacted the sealing surface. Surface management enabled them to gain a new sensitivity to surfaces, visibility to where contaminants were introduced, and allowed them to create strategies to fix the problems prior to the product going to mass production.

In this case, the supply chain and the OEM were not aligned on a cleanliness standard and did not understand how surface chemistry impacts the final performance of the product or how certain processes internally impact the performance of the product once it is shipped to the OEM. As a result, the work that they were doing was hurting the downstream manufacturing processes.

Summary

Manufacturers have an opportunity to take advantage of surface chemistry. Leading manufacturers across the globe are now investing in surface intelligence that enables them to advance their product innovation and manufacturing performance. If a manufacturer or organization fails to realize the importance of surface chemistry and the innovation it can promote, it will always be a step behind its competitors.

Optimize the power of next-gen connectivity with data & surface intelligence.

At Brighton Science, we have surface chemistry experts that can help any manufacturer or supply chain business improve its performance while also ensuring that the surfaces are being managed correctly and to specification. We have extensive knowledge of surface science and chemistry and the innovative tools that can be used to overcome these issues.

Download the eBook, The Advanced Guide to Transforming Product Development Through Surface Intelligence Data & Technology, to learn how your business can be a step ahead of the competition by implementing surface intelligence to control surfaces in manufacturing.