An aerospace spacecraft manufacturer uses the Handheld Surface Analyst 5001 to confirm surface readiness.

The Challenge

The client was concerned about the bonding of composite materials in a structural component of their spaceship. Their surface preparation method was manual, including a solvent wipe, hand sanding, and final solvent wipe. The process left plenty of room for human error and could not measure and monitor consistency, allowing for uncertainty and potential for failure and re-work. The client needed an accurate, quantifiable method to monitor the surface treatment process confidently.

The Brighton Science Approach

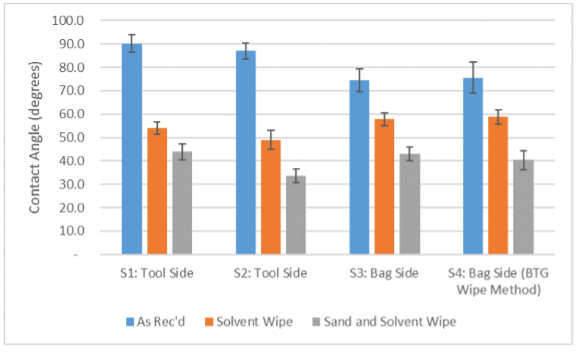

The manufacturer sent a sample of their material component to Brighton Science’s Materials and Processing Lab. The Brighton engineers used the Handheld Surface Analyst 5001 to examine their process step-by-step. Three contact angle measurements were taken on four areas of the part. The first measurement was on the as-received sample, the second measurement was taken after the first solvent wipe, and the third was taken after the sanding and final solvent wipe. The Surface Analyst showed the sample’s decrease in contact angle through the preparation process (Fig. 1).

The Solution

The Brighton Science team then helped the client determine contact angle pass/fail parameters that could be loaded into the Surface Analyst, allowing the surface preparation process to flow seamlessly on the manufacturing floor. The client has an objective, reliable in-line method to measure and monitor the surface treatment process.

Figure 1: Composite preparation process monitored with the Surface Analyst. Final contact angles correlate to the bond strength required for this application. Contact angle parameters can vary depending on the application.