Key Takeaways

- Supplier changes can introduce subtle surface-related risks that traditional quality checks may not detect

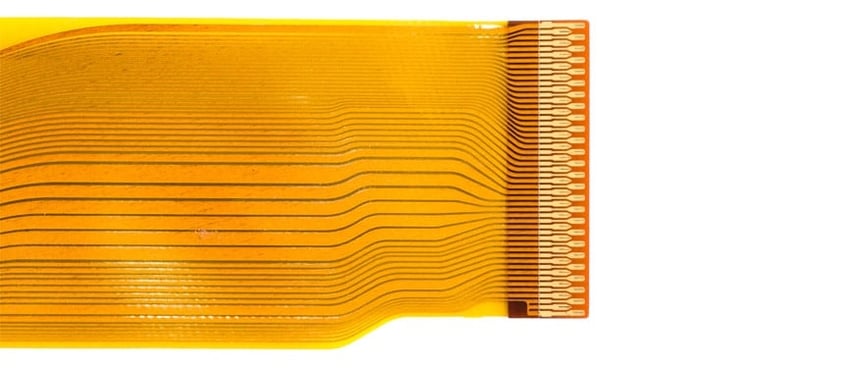

- Circuit board printing on polyimide film is highly sensitive to surface cleanliness and consistency

- Without objective surface specifications, supplier quality expectations can be misaligned

- Quantitative surface measurement enables clearer communication with global suppliers

- Verifying surface condition before shipment helps prevent downstream adhesion failures

When Supplier Changes Disrupt a Stable Printing Process

Supplier quality assurance is especially challenging for surface-sensitive processes like circuit board printing. Even when materials appear identical on paper, small differences in surface condition can significantly affect adhesion and print quality.

In this case, a U.S.-based printing OEM began experiencing adhesion failures while printing circuit boards onto polyimide film after switching from a domestic film supplier to an international one. The process had previously been reliable enough that incoming surface checks were not required. Once the supplier changed, that assumption no longer held.

The OEM quickly lost confidence in the surface cleanliness of the incoming film. Traditional material certifications and visual inspections offered no clear explanation, yet print failures continued to occur. It became clear that the issue was not the printing process itself, but an uncontrolled surface variable entering from the supply chain.

Why Surface Condition Matters in Circuit Board Printing

Printing conductive circuits onto polymer films depends on intimate interaction between the ink and the substrate. That interaction is governed by the outermost molecular layers of the material.

Surface contamination or inconsistent surface chemistry can prevent proper wetting and adhesion, even when bulk material properties remain unchanged. Without a way to measure and define acceptable surface condition, suppliers and OEMs are often left relying on indirect indicators or past experience.

In this case, the OEM needed a way to objectively evaluate whether the polyimide film arriving from abroad was truly suitable for their printing process, before it ever entered production.

Regaining Supplier Consistency Through Objective Surface Measurement

Measurement was the missing link in the OEM’s supplier quality process. Prior to the supplier change, surface condition had never been quantified because the printing process had been stable and predictable. Once failures appeared, surface cleanliness needed to be treated as a controllable input rather than an assumed material property.

By using quantitative surface measurements, the OEM was able to directly compare polyimide film from the original domestic supplier with material from the new international supplier. This comparison revealed a clear and measurable difference in surface condition between the two sources.

With an objective surface requirement defined, the expectation for the supplier became unambiguous. The international supplier could now monitor and adjust their process to meet the required surface cleanliness level, rather than relying on trial-and-error adjustments.

As a result, the OEM established a practical supplier check both before and after shipping. Surface condition could be verified remotely, batch-to-batch variation could be identified early, and adhesion failures were prevented before material ever reached production. By controlling surface quality as an input variable, the printing process returned to consistent, reliable performance.

Strengthening Supplier Quality Programs Going Forward

This case highlights a common challenge in supplier quality assurance: surface condition often plays a critical role in product performance, yet it is rarely specified, measured, or communicated clearly.

Once surface quality became measurable and comparable, the OEM was able to align expectations with its supplier and restore confidence in the supply chain. The approach transformed supplier quality from a reactive troubleshooting exercise into a proactive verification process.

Take the Next Step With BConnect

While this OEM relied on direct surface measurements to regain control, many manufacturers now extend this approach by digitizing surface specifications, supplier data, and historical trends across programs and locations.

BConnect helps manufacturers:

- Define and manage quantitative surface specifications

- Track supplier performance over time

- Identify variation before it impacts production

- Support data-driven supplier quality conversations

Explore how BConnect can strengthen your supplier quality assurance strategy for surface-critical manufacturing processes.

FAQs

Q: Why did adhesion problems appear only after switching suppliers?

A: Surface condition can vary significantly between suppliers, even when materials appear identical. These differences often exist at the molecular level and are not detected by traditional inspections.

Q: Why is surface cleanliness critical for circuit board printing?

A: Ink and conductive traces must wet and adhere to the substrate. Surface contamination or inconsistent surface chemistry can prevent proper adhesion.

Q: Can traditional supplier audits catch surface-related issues?

A: Not reliably. Audits and certifications rarely measure the molecular-level surface properties that govern adhesion and print performance.

Q: How can OEMs prevent similar supplier quality issues?

A: By defining objective, quantitative surface requirements and verifying surface condition before material enters production.

Q: Is this approach limited to electronics manufacturing?

A: No. Any surface-sensitive process, including bonding, coating, sealing, and painting, can benefit from objective surface measurement.