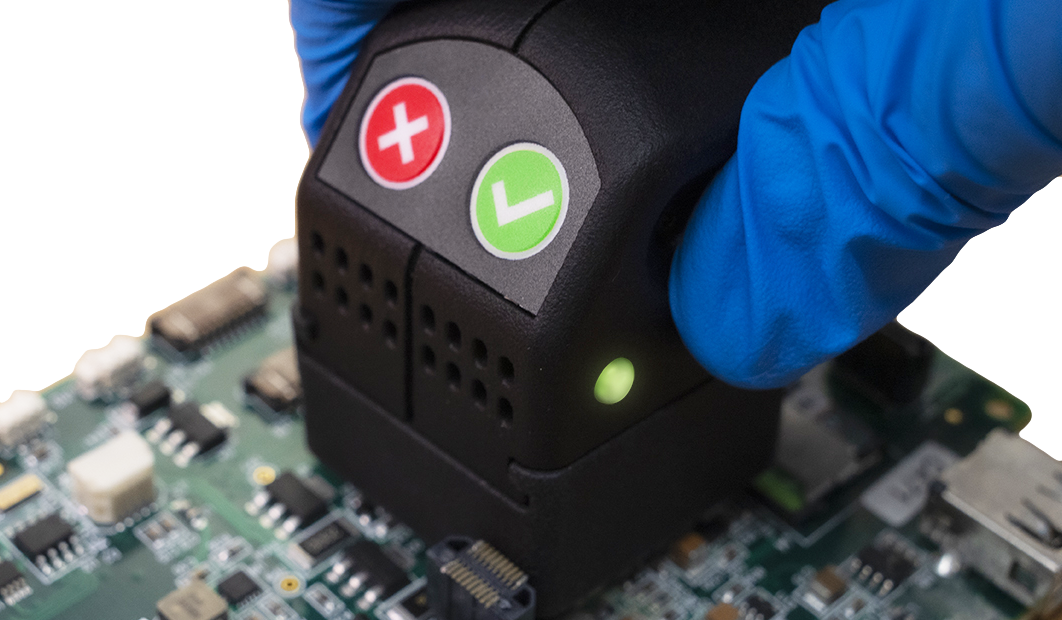

By standardizing surface preparation processes and adopting surface energy measurement, a company can achieve uniformity, quality and cost reduction.

Discover how Brighton Science is revolutionizing surface prep standardization and garnering attention in the latest Products Finishing article, "Mastering Uniformity Through Surface Prep Standardization."

Surface preparation is a critical step in ensuring product performance, appearance and durability. However, variations in surface preparation processes can lead to inconsistencies, inefficiencies and compromised quality. By leveraging best practices, advanced technologies such as surface energy measurement and effective change management strategies, manufacturers can achieve uniformity, high-quality products and cost reduction. In fact, programs from automotive to aerospace manufacturing have saved 3% to 10% in rework by doing so.

The Importance of Standardization

Standardization offers numerous advantages to manufacturers, including:

- Reduced Program Cost.

By ensuring multiple sites are performing the same standard surface preparation, measurement and monitoring, programs reduce costs that are incurred through human-induced variation. - Consistency.

Standardizing surface preparation processes ensures the same procedures are followed across all production lines and facilities. This eliminates variations that can lead to product defects, rework and customer dissatisfaction. - Efficiency.

Standardized processes optimize resource allocation, reduce waste and streamline operations. This leads to improved productivity and cost savings over time. - Quality Control.

Uniformity in surface preparation processes enhances quality control mechanisms by enabling accurate monitoring, measurement and corrective actions. Deviations from standards become more noticeable and can be addressed promptly. - Training and Skill Enhancement.

A standardized process facilitates training and skill development for operators and technicians as they become proficient in executing a single, well-defined procedure.