Dr. Rose Roberts of Brighton Science has authored a significant technical paper for converting dyne values to water contact angles (WCA), offering a bridge between the two measurement methods. In her technical paper titled "Creating a Dyne to Water Contact Angle Conversion for Your Materials," Dr. Roberts sheds light on the significance of this correlation and provides guidelines for its practical implementation.

Understanding Dynes and Water Contact Angles

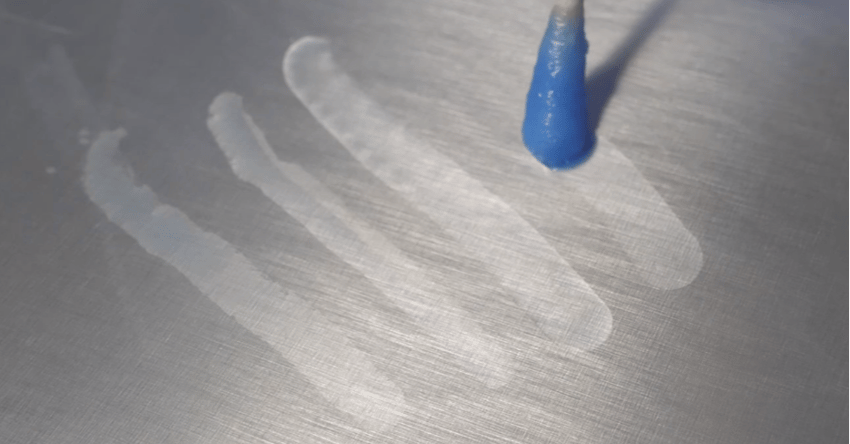

Dyne testing, often used to estimate a material's surface energy, has long been a staple in quality control. However, it has its shortcomings, including subjectivity and insensitivity to contaminants. Dr. Roberts outlines the challenges posed by dyne solutions and highlights the need for a more objective and versatile measurement method – WCA.

WCA directly measures surface wettability by observing the shape of a water droplet on the surface. This method provides superior sensitivity to subtle variations in surface composition and treatment levels, making it a valuable alternative.

Creating the Correlation

Dr. Roberts presents a comprehensive guide to establishing a correlation between dyne values and WCAs. To do this, surface states must be induced on materials to gather sufficient data points for an accurate correlation. Key steps include assessing "As Received from Supplier," "Cleaned," and different treatment levels.

The conversion process involves taking WCA measurements followed by dyne measurements and plotting the data using a second-order polynomial trendline. This correlation allows companies to transition smoothly from dyne measurements to WCAs while simultaneously creating a link between these measurements, process parameters, and product performance.

Benefits and Potential Observations

The correlation method presented by Dr. Roberts offers greater sensitivity to surface variations and low treatment levels, making it a valuable tool for quality control and process improvement. It can detect subtle changes in surface composition and contamination that may go unnoticed with dyne testing.

The paper addresses common issues, such as reaching the maximum measurable dyne values and the impact of contaminants on dyne measurements. Dr. Roberts' research provides a valuable resource for industries looking to enhance their surface quality control processes. The ability to convert dyne values to water contact angles offers a more objective, sensitive, and versatile approach to assessing surface energy, paving the way for improved product quality and performance.

If you’re interested in learning more about this conversion process or getting a copy of Dr. Roberts’ technical paper, book a meeting with us today!

Struggling with adhesion failures? Been there. Solved that.

Are you interested in reading other content related to dyne testing and surface science? Check out our Insights page, where you will find articles, eBooks, technical papers, videos, and more!