Brighton Science has released a new eBook titled "What is Dyne Testing?" shedding light on the widely used method for measuring surface energy in manufacturing processes. Dyne testing is a technique that assesses the wetting tension of a solid by applying a liquid with a known surface tension to its surface. This measurement, expressed in dynes per centimeter (dynes/cm), approximates the force required to spread a fluid across the material's surface.

The key principle behind dyne testing is that a higher dyne value indicates a higher wetting tension of the solid surface, which, in turn, correlates with higher rates of successful adhesion. For years, dyne testing has been a popular approach for evaluating the cleanliness and surface energy of materials in manufacturing settings despite its limitations in precision and potential harm to material surfaces and users.

Dyne testing relies on the concept of surface energy directly related to a material's adhesive potential. When a dyne solution is applied to a substrate, it can either bead up or disperse. Beading indicates lower surface energy in the material compared to the solution, while a continuous layer suggests higher surface energy in the material. This test aims to provide users with information about a material's dyne level.

Manufacturers often create specifications based on their adhesion goals and correlate them with dyne test pen numbers. Technicians apply the ink with the agreed-upon number and visually inspect whether it wets out enough, passing the test to move the part forward in production.

While dyne testing is prevalent, it has notable limitations, including variability between brands of dyne pens and the potential for human error in interpretation. Furthermore, dyne inks can contain hazardous chemicals, leading to environmental concerns and health risks for users.

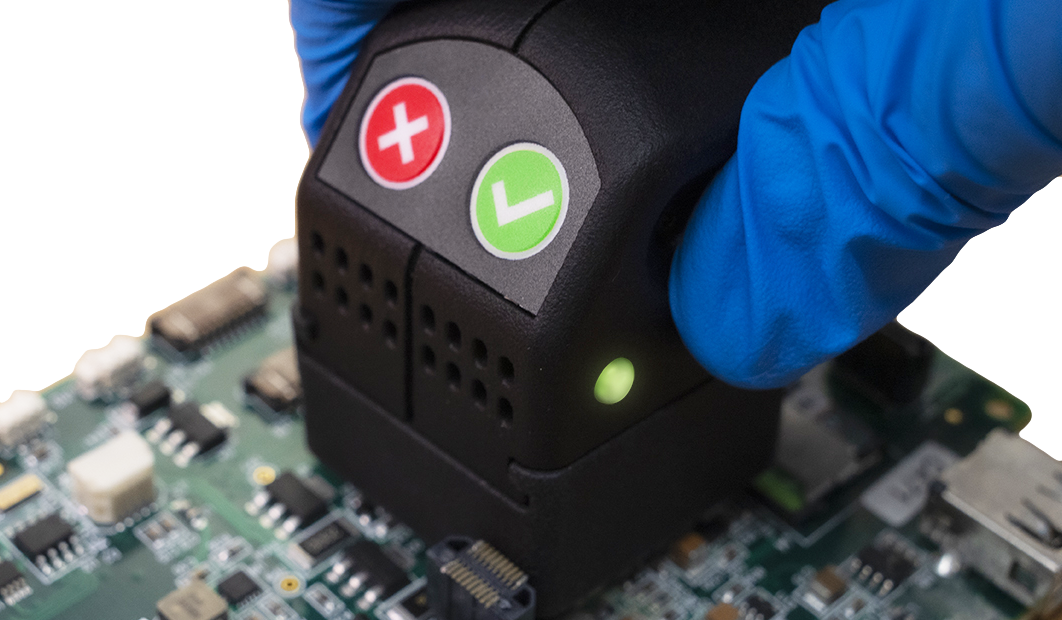

The eBook also highlights the importance of considering alternatives to dyne testing. One such alternative is water contact angle measurements, which offer quantitative, non-subjective data about surface cleanliness and composition. Tools like the Surface Analyst provide rapid and accurate contact angle measurements, reducing the risk of contamination and human error. This technology is suitable for a wide range of materials and manufacturing processes.

Manufacturers interested in transitioning from dyne testing to contact angle measurements can seek assistance from experts like Brighton Science. This transition introduces a new protocol that enhances efficiency and precision in manufacturing processes.

In conclusion, the newly released eBook "What is Dyne Testing?" provides valuable insights into the world of dyne testing in manufacturing, its limitations, and alternatives such as water contact angle measurements. As manufacturers seek more reliable and efficient ways to assess surface energy, this eBook offers a comprehensive guide to making informed choices.

![Dyne Testing in Manufacturing: A Comprehensive Guide [+ Alternatives]](https://www.brighton-science.com/hs-fs/hubfs/images/blog-images/dyne%20ebook%20news%20article%20banner%20%282%29.png?width=850&height=496&name=dyne%20ebook%20news%20article%20banner%20%282%29.png)