In manufacturing, consistent and high-quality products are paramount to success. Surface preparation is critical in ensuring product performance, appearance, and durability. However, variations in surface preparation processes across an enterprise can lead to inconsistencies, inefficiencies, and compromised quality.

This article will explore surface preparation in manufacturing, common surface preparation methods, and surface preparation standards while addressing concerns related to quality. By harnessing proper surface preparation best practices, cutting-edge technologies, and strategic change management initiatives, manufacturers can achieve both uniformity in results and excellence in execution. This approach unlocks immediate cost reductions, as evidenced by rework savings of 3-10% observed in diverse manufacturing programs ranging from automotive to aerospace.

What is Surface Preparation?

Let’s begin answering this question by first defining what a surface is (as it relates to adhesion). A surface is the uppermost few layers of molecules comprising the free surface of a substance. The properties of these few molecular layers determine if an adhesive, coating, or paint will adhere or release (fail).

Surface Preparation is the process of generating the surface of a substrate that is acceptable to the application of an adhesive or coating. Surface preparation and treatment are critical in ensuring successful bonding by strategically altering the surface's molecular composition and removing surface contamination.

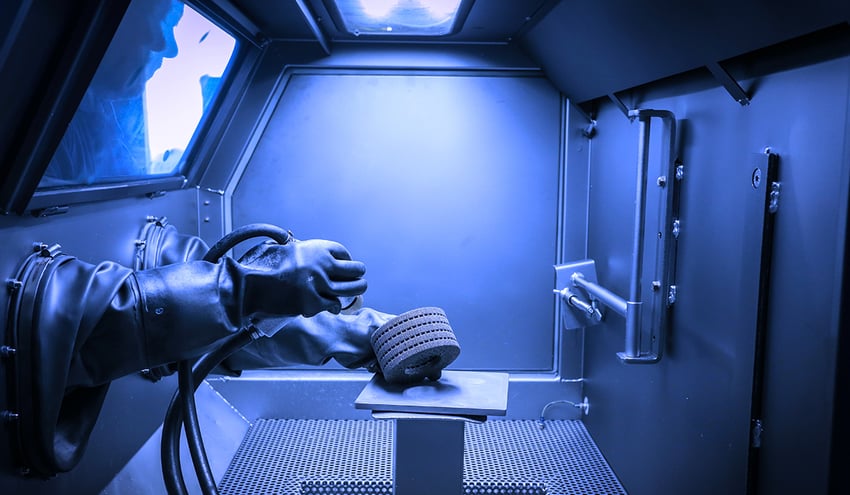

Common types of surface preparation, treatment, and cleaning methods include:

- Sanding

- Grit blasting (abrasive blasting)

- Solvent cleaning

- Chemical etching

- High-pressure water jetting

Why Does Surface Prep Matter in Manufacturing?

Success in bonding and coating hinges on the unseen. Your "surface" is just a few molecular layers deep, holding the key to strong adhesive bonding and coating adhesion. Its chemical makeup, often altered by contaminants (foreign matter), dictates how coatings, paints, and adhesives interact. We remove these unseen foes through careful surface prep, ensuring lasting bond performance.

Surface prep isn't just about creating a clean surface; it's understanding and managing the invisible interactions that create reliable, high-quality products.

Read more about surface treatment methods for manufacturers in this article, “What is Surface Treatment? A Comprehensive Guide to Surface Treatment Methods for Manufacturers.”

Why Surface Preparation Standards?

A meticulously designed surface preparation methodology and specification is essential to guarantee the integrity and long-term performance of bonding and coating systems. This critical foundational process is essential for meeting customer expectations and maintaining competitive advantage, whether it's cleaning metal surfaces for automotive components assembly, eliminating the risk of electronics corrosion, or ensuring a coating doesn’t flake or fail.

Surface preparation standardization offers numerous benefits to manufacturing enterprises, including:

- Reduced Program Cost - By ensuring multiple sites perform the same standard surface preparation, measurement, and monitoring, programs reduce costs incurred through human-induced variation, whether induced via unintended human choices or through unknown contamination entering the process.

- Consistency - Standardizing prepared surfaces ensures the same procedures are followed across all production lines and facilities. This eliminates variations in cleanliness levels that lead to product defects, rework, and customer dissatisfaction.

- Efficiency - Standardized processes optimize resource allocation, reduce waste, and streamline operations, improving productivity and cost savings over time.

- Quality Control - Uniformity in surface preparation processes enhances quality control mechanisms by enabling accurate monitoring, measurement, and corrective actions. Deviations from standards become more noticeable and can be addressed promptly.

- Training and Skill Enhancement - A standardized process facilitates training and skill development for operators and technicians as they become proficient in executing a single, well-defined surface cleanliness procedure.

Quality Assurance in Standardization

Concerns about compromising quality when implementing standardization can be addressed through the following approaches:

- Collaborative Process Development - Involve cross-functional teams in developing standardized processes, including engineers, quality control experts, and operators. This ensures that quality considerations are embedded into the process from the outset.

- Best Practices Integration - Standardization should be based on industry best practices and established quality standards. This ensures that the standardized process is already aligned with high-quality expectations.

- Performance Metrics - Establish clear performance metrics to assess the effectiveness of standardized processes. Regular monitoring and data-driven analysis help identify areas of improvement and ensure quality remains a priority.

- Continuous Improvement - Implement a culture of continuous improvement where feedback from operators and quality control teams is actively solicited. This enables adjustments to the standardized process based on real-world insights.

Leveraging Advanced Technologies

Modern technologies play a crucial role in ensuring standardized surface preparation processes maintain or enhance quality:

- Automation and Robotics - Automated systems ensure consistent execution of surface preparation processes, minimizing human error and variability.

- Precision Measurement Tools - Incorporating advanced measurement technologies guarantees accurate surface quality assessment, enabling immediate corrective actions if deviations occur.

- Data Analytics - Utilize data analytics to monitor process performance, detect trends, and predict potential quality issues before they impact product integrity.

- Simulation and Modeling - Digital simulations can help optimize and validate standardized processes before implementation, reducing the risk of quality-related setbacks.

Change Management Strategies

Implementing standardized surface preparation processes requires effective change management to address resistance and ensure successful adoption:

- Communication: Transparently communicate the rationale behind surface preparation standardization and its benefits for both the organization and individual roles.

- Training and Education: Invest in comprehensive training programs to equip employees with the skills and knowledge needed to execute standardized processes effectively.

- Employee Involvement: Involve employees in the standardization process to gain their buy-in and input, fostering a sense of ownership.

- Gradual Implementation: Roll out standardized processes incrementally, allowing teams to adapt and learn gradually without overwhelming them.

Standardizing a Toolset and Measurement Language

In the competitive manufacturing landscape, consistency and quality are prerequisites for success. Standardizing surface preparation processes across the enterprise offers numerous advantages, from improved quality control to enhanced efficiency. By embracing best practices, leveraging advanced technologies, and employing effective change management strategies, manufacturers can achieve the delicate balance of uniformity without sacrificing quality.

The road to standardized excellence begins with a commitment to continuous improvement and a focus on delivering products that consistently exceed customer expectations. Of course, the correct solution set needs to be implemented for this to work smoothly.

Use BConnect™ to Improve Cost Efficiency

By adopting a consistent method of measuring surface readiness and tailoring preparation processes to specific requirements, companies can streamline operations, enhance product performance, and save money through reduced material waste, rework, and increased efficiency. Leveraging a solution like BConnect™ makes this concept a reality for manufacturers today.

To learn how your business can successfully build a surface preparation standard to gain a competitive advantage, download the eBook “Mastering Uniformity: Surface Preparation Standardization Across the Enterprise.”