Key Takeaways

- RTV silicone adhesives require exceptionally clean surfaces for reliable bonding, especially in environments with hydrocarbons.

- Traditional inspection methods like dyne inks are subjective and prone to error, leading to leaks and rework.

- Objective surface measurement using water contact angle provides quantifiable cleanliness data before sealing.

- Standardized pass/fail criteria across suppliers and assembly lines eliminate guesswork and ensure consistency.

- Integrating surface data into digital process control systems like BConnectSM drives predictability and traceability in RTV sealing applications.

The Challenge: RTV Adhesion Failures in Engine Sealing

Room Temperature Vulcanizing (RTV) silicone sealants have replaced traditional gaskets in many automotive applications due to their flexibility, ease of application, and cost-effectiveness. However, their performance depends heavily on one critical factor: surface cleanliness.

In the automotive industry, hydrocarbons are unavoidable. Oil residues, machining lubricants, and handling contaminants all interfere with RTV adhesion. For a large American automotive manufacturer, this issue surfaced in the form of engine leaks in the field, prompting a comprehensive review of their cleaning and bonding processes.

The Existing Process: Cleaning and Testing Limitations

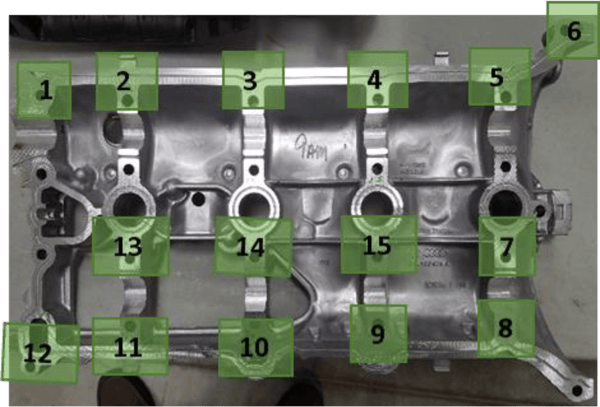

The manufacturer primarily worked with diecast and machined aluminum components, cleaned through a combination of washing, plasma treatment, and conversion coating. Despite these steps, bond failures persisted.

To verify cleanliness, the team initially relied on dyne inks—a common but flawed method. Dyne tests provide a visual indication of surface energy, but results can vary widely between operators and environments. The lack of quantifiable, repeatable data made it impossible to identify when and where contamination entered the process.

Suppliers faced similar uncertainty, unable to confirm whether incoming aluminum parts met cleanliness specifications before assembly. The result: inconsistent seals and recurring leakage issues.

The Turning Point: Measuring Surfaces Objectively

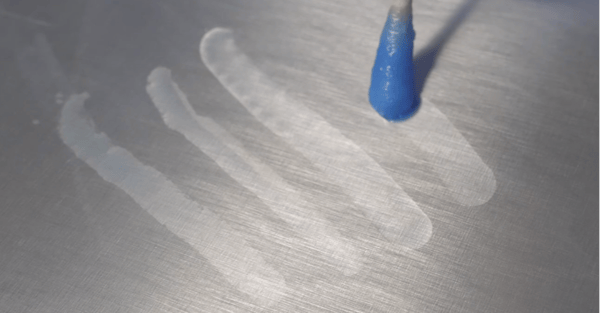

An engineer within the organization discovered Brighton Science while researching ways to measure surface cleanliness more reliably. By implementing Brighton's patented Surface Analyst™ technology, the team conducted over 10,000 water contact angle measurements across different cleaning conditions.

These measurements quantified surface energy objectively, revealing the relationship between specific cleaning parameters and successful RTV adhesion. With this data, the manufacturer established a pass/fail threshold—a measurable criterion that defined what “clean enough” truly meant for RTV bonding.

This standard was then shared across their supplier network and production facilities, ensuring everyone worked toward the same, data-backed cleanliness goal.

The Result: Reliable, Leak-Free Engine Assembly

By adopting objective surface measurement, the automotive manufacturer eliminated the subjectivity and material waste caused by outdated testing methods. The Surface Analyst enabled rapid, nondestructive testing directly on production parts, ensuring each surface was ready for RTV application.

As a result:

- Engine leaks were eliminated through verified surface preparation.

- Suppliers gained clear specifications for surface cleanliness.

- Process efficiency improved, reducing rework and warranty claims.

The Bigger Picture: From Measurement to Intelligence

This case exemplifies how surface data becomes a cornerstone of Surface Intelligence. When paired with a digital platform like BConnect, these measurements can be tracked, analyzed, and correlated with quality outcomes, allowing manufacturers to predict and prevent adhesion failures before they occur.

Objective, traceable surface data transforms RTV sealing from a reactive process to a controlled, repeatable, and measurable system—a key requirement in modern, quality-centered manufacturing.

Learn how to bring objective Surface Intelligence to your sealing processes with BConnect, the platform built for traceable, data-driven manufacturing.

Struggling with adhesion failures? Been there. Solved that.

FAQs

Q: What is RTV and why is it used instead of gaskets?

A: RTV (Room Temperature Vulcanizing) silicone is a flexible, durable sealant that cures at room temperature. It replaces traditional gaskets in many applications due to easier application, cost savings, and excellent temperature resistance.

Q: Why do hydrocarbons affect RTV adhesion?

A: Hydrocarbons such as oils, greases, and machining fluids form a thin film on metal surfaces, preventing the RTV from making full molecular contact. Even trace residues can lead to bond failure.

Q: Why are dyne inks unreliable for cleanliness testing?

A: Dyne inks depend on human observation and can vary with humidity, temperature, and operator technique. They provide qualitative data at best, making them unsuitable for precise surface control.

Q: How does water contact angle measurement improve RTV sealing?

A: Water contact angle (WCA) directly measures a surface’s energy level—quantifying how clean or contaminated it is. Lower contact angles indicate higher surface energy and better bonding conditions for RTV.

Q: How does BConnect enhance RTV process control?

A: BConnect centralizes and analyzes surface measurement data, connecting supplier and production results to quality outcomes. This enables real-time monitoring, traceability, and data-driven decision-making across the supply chain.