How Many Measurements Are Enough to Make Quality Decisions?

A surface that has been properly prepared for coating, painting, or adhesive bonding will have a certain average contact angle that is determined primarily by the chemical composition of the surface. Because of slight variations in the surface composition combined with the variation inherent in any...

Read

Topics:

Posts by Topic

Water Contact Angle Correlation to Crosshatch Adhesion Tape Test in Accordance with ASTM D3359-09

Manufacturers are familiar with adhesion challenges when attempting to bond, paint, etch, or coat a substrate. Poorly prepared surfaces can undoubtedly produce problematic adhesion issues.

Read

Topics:

Rapid Evaluation of Surface Properties of Medical Tubing for Process Development and Quality Assurance

This paper is a joint creation between Brighton Science and Teleflex Inc., a prominent provider of medical devices such as medical tubing.

Read

Topics:

Contact Angle Measurements and Surface Analysis of Atmospheric Pressure Plasma Treated Polypropylene

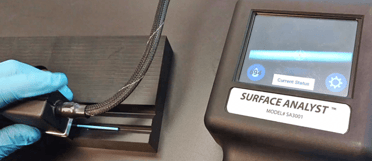

The Surface Analyst™ rapidly obtains contact angle measurements from surfaces via Ballistic Deposition, whereby a small drop of liquid (usually water) is constructed in situ on the surface via a pulsed stream of nanoliter-sized droplets.

Read

Topics:

Gage Repeatability and Reproducibility of the Surface Analyst

Gage Repeatability and Reproducibility are valued measures of a gauge’s appropriateness for use in a specific application.

Read

Topics: