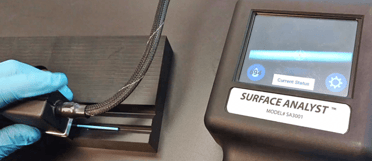

The Surface Analyst's Innovative Method of Depositing Water to Measure Contact Angle: Ballistic Deposition

Discover how the Surface Analyst's unique method of depositing water onto a surface enables precision contact angle measurements on real-world surfaces. The forces acting on a liquid drop in contact with a surface can be represented as the surface energy of the solid, the surface tension of...

Read

Topics:

Posts by Topic

How Many Measurements Are Enough to Make Quality Decisions?

A surface that has been properly prepared for coating, painting, or adhesive bonding will have a certain average contact angle that is determined primarily by the chemical composition of the surface. Because of slight variations in the surface composition combined with the variation inherent in any...

Read

Topics:

Single Fluid Contact Angle Measurements Make Process Control Easier

Polar interactions between a properly prepared surface and an ink, adhesive, or coating are strong and are responsible for most of the required adhesion of inks, paints, and adhesives.

Read

Topics:

Utilizing Water Contact Angle Measurements to Predict Surface Preparedness for Dye Penetrant Application

Reliably predicting dye penetrant wettability for fluorescent crack inspections hinges on understanding surface cleanliness prior to penetrant application.

Read

Topics:

Rapid Development of Surface Treatment Processes for Bonding Dissimilar Materials

A recent concept in automotive lightweighting is that of the ‘joining of dissimilar materials.’ The purpose is to allow tailoring the materials in a structure so as to ensure that each part of the structure has the optimum mechanical properties and minimum weight. An example would be the bonding of...

Read

Topics:

Correlating Water Contact Angle With Water Break Measurements as an Indicator of Surface Energy

The water break test is a common pass/fail method used to evaluate surfaces for the presence of hydrophobic contaminants, which can be detrimental to the adhesion performance of paint or an adhesive. It is a qualitative means of evaluating surface energy, which is directly related to surface...

Read

Topics:

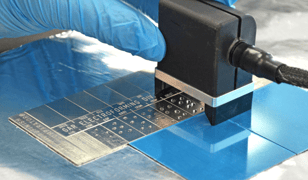

Water Contact Angle Correlation to Crosshatch Adhesion Tape Test in Accordance with ASTM D3359-09

Manufacturers are familiar with adhesion challenges when attempting to bond, paint, etch, or coat a substrate. Poorly prepared surfaces can undoubtedly produce problematic adhesion issues.

Read

Topics:

Rapid Evaluation of Surface Properties of Medical Tubing for Process Development and Quality Assurance

This paper is a joint creation between Brighton Science and Teleflex Inc., a prominent provider of medical devices such as medical tubing.

Read

Topics:

Rapid Surface Treatment Quality Checks for Reliable Polymer Adhesion

This work presents the results of investigations into the ability of the ballistic drop deposition technique to measure surface treatment in the corona and flame-treated oriented polypropylene films.

Read

Topics:

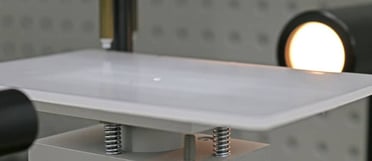

Effect of Surface Roughness on Contact Angle Measurements Obtained with the Surface Analyst

A frequent question from people who use contact angle measurements to characterize surfaces and control manufacturing processes is, “What effect does surface roughness have on these measurements?” This is a valid question, especially when dealing with surfaces that have a range of textures...

Read

Topics:

Effect of Grit-Blasting on the Surface Energy of Graphite/Epoxy Composites

Composites consisting of polymer matrices reinforced with graphite fibers are attractive materials for structural applications in the aerospace industry because they are light in weight and have a high strength-to-weight ratio.

Read

Topics:

Water Contact Angle as a Quantitative Measure of Total Polyethylene Surface Energy

A wide variety of plasma treatments were performed on polyethylene surfaces, resulting in a wide range of total surface energies.

Read

Topics:

The Surface Analyst: Advanced Goniometry for Manufacturing

There are fundamental differences between an NRL-style goniometer and the Surface Analyst, most of which contribute to the value of the measurement for the development and control of surface-sensitive manufacturing processes.

Read

Topics:

How Solvent Wiping and Sanding Affect Surface Energy and Cleanliness

Solvent wiping and sanding procedures can greatly affect the surface energy of a substrate. To investigate the surface energy differences following different preparation procedures of an epoxy/composite laminate, several different surface conditions were created utilizing different cleaning...

Read

Topics: