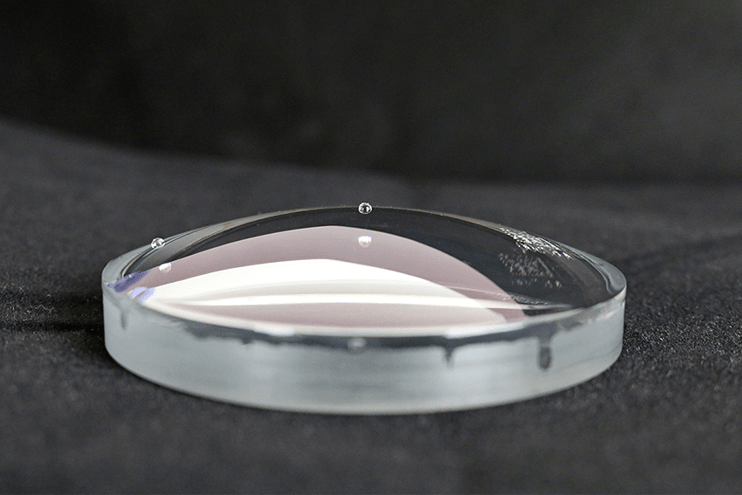

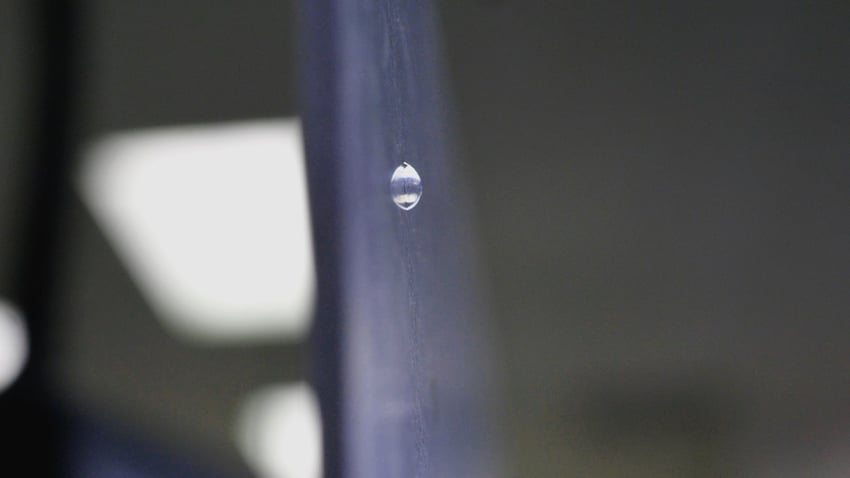

Polar interactions between a properly prepared surface and an ink, adhesive, or coating are strong and are responsible for most of the required adhesion of inks, paints, and adhesives.

These interactions are greatly affected by cleaning processes and surface treatment. Non-polar (or dispersive) interactions are relatively weak, are insensitive to cleaning and surface treatment, and their measurement requires the use of hazardous fluids.

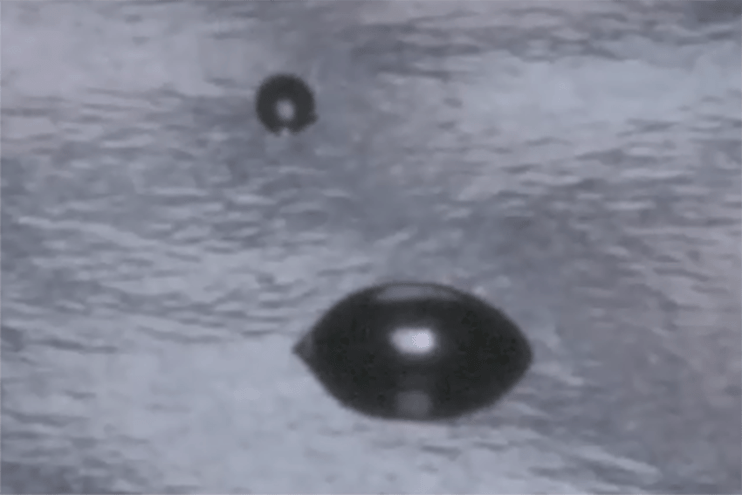

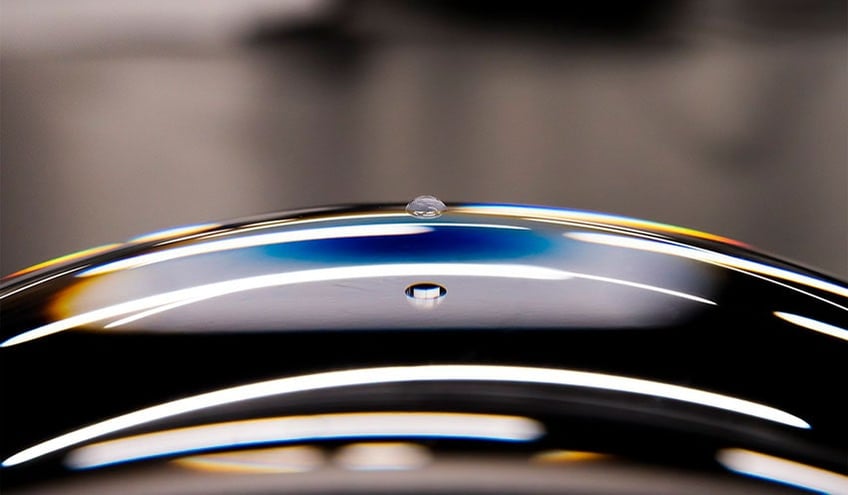

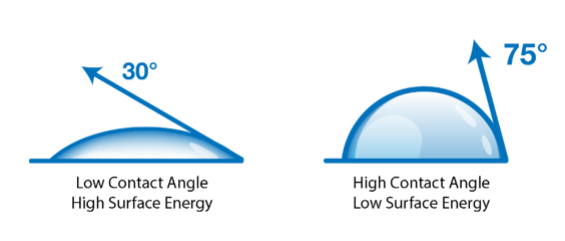

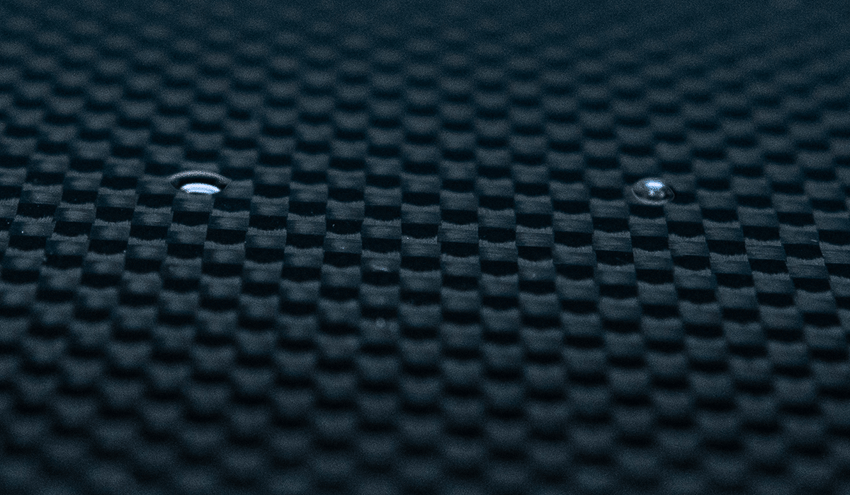

As a result, the best metrics for measuring and controlling the surface properties important for adhesion are the ones that are most sensitive to the polar characteristics of a surface. A single water contact angle measurement provides this sensitivity without the need for multiple probe fluids.

Read the full paper here: Why One Contact Angle Fluid is All You Need to Control Your Process