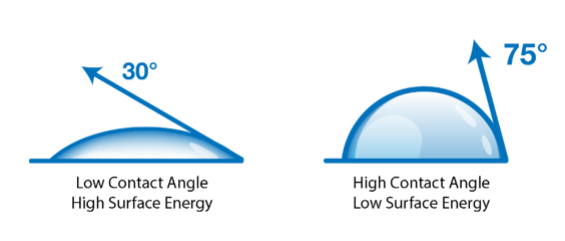

Of all the challenges manufacturers face, creating and optimizing critical surface processes for various materials can be very difficult. Traits such as location, size, shape, and texture can add to the challenge. The success of any critical surface process requires an in-line, fast, easy, and accurate verification method. That’s why more and more manufacturers are turning to the Surface Analyst analysis. Whether bonding, painting, printing, cleaning, coating, or sealing, the Surface Analyst™ technology optimizes critical surface processes and monitors surface treatment on virtually any surface, so the product is guaranteed to deliver.

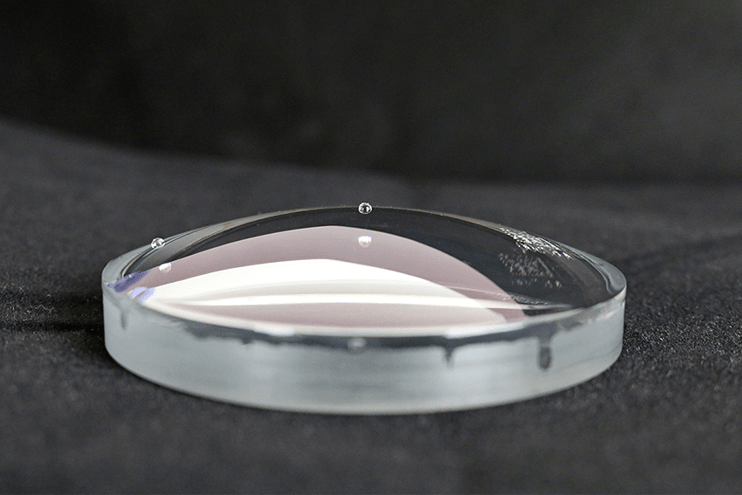

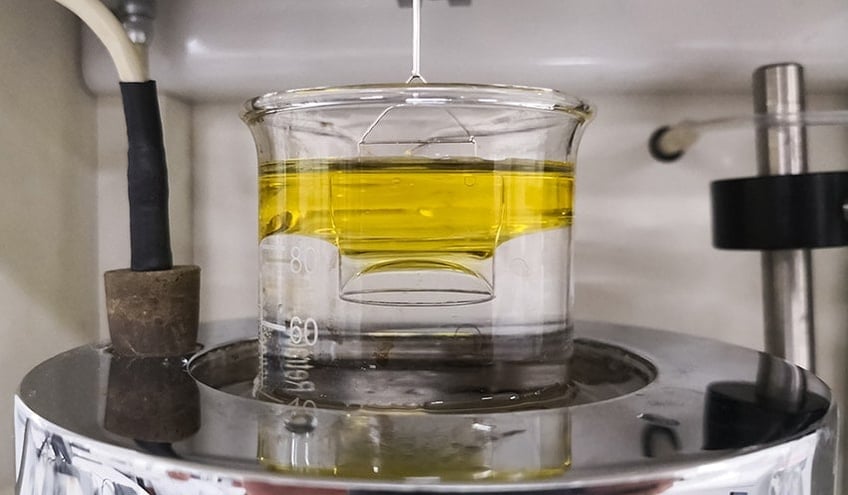

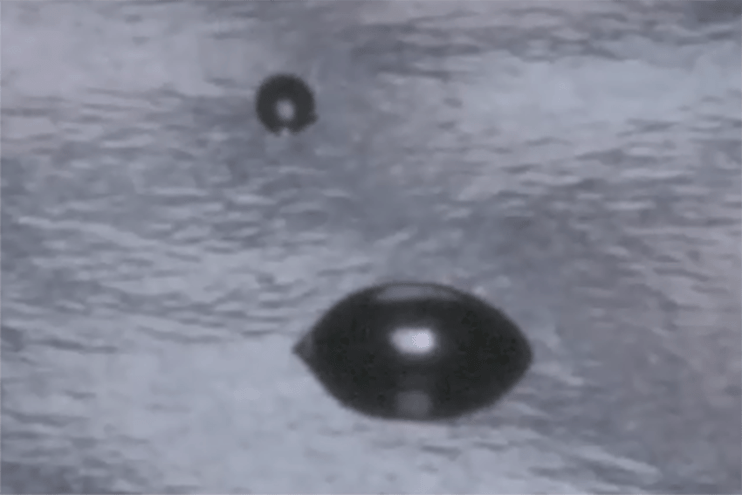

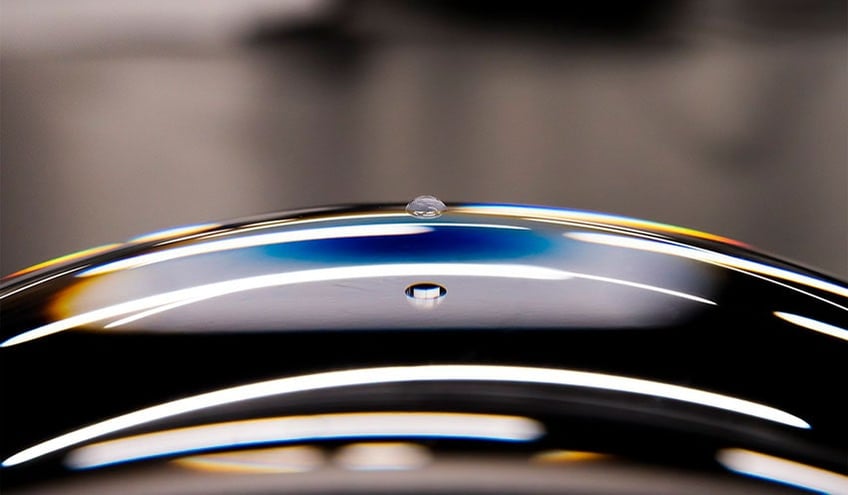

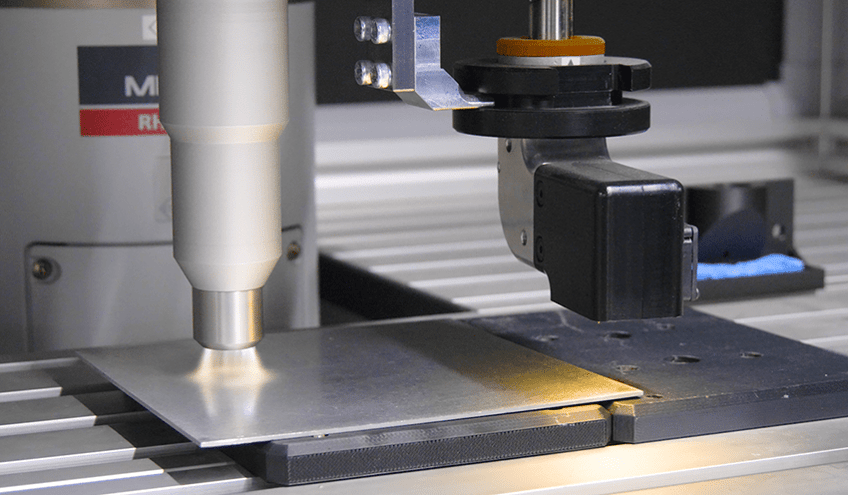

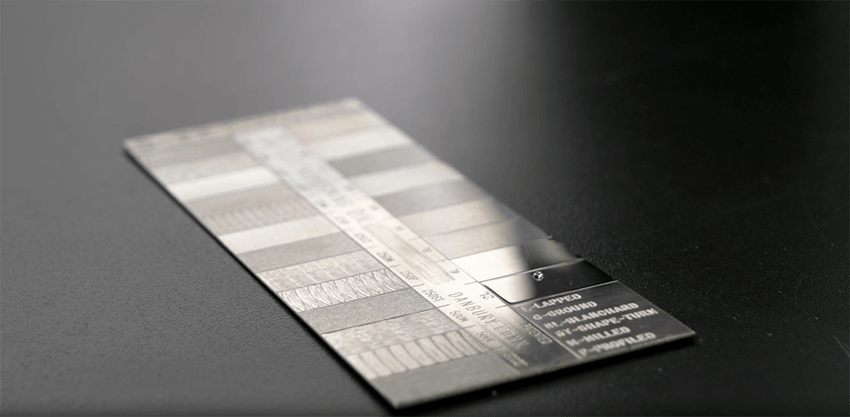

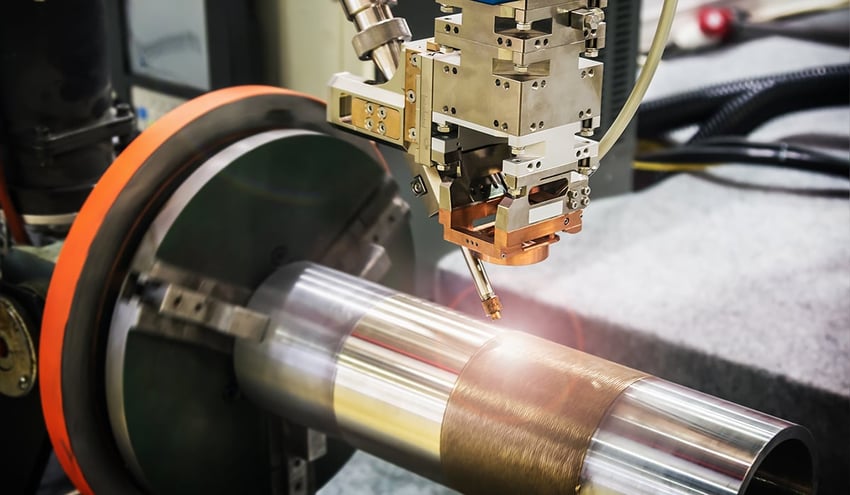

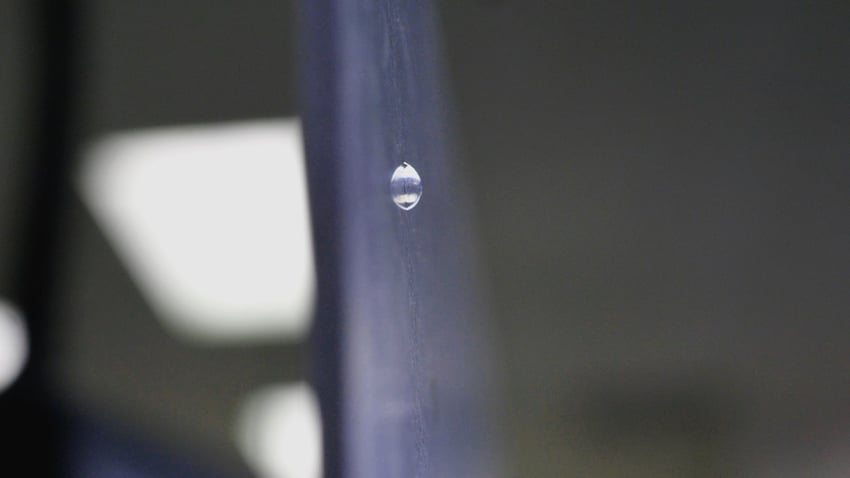

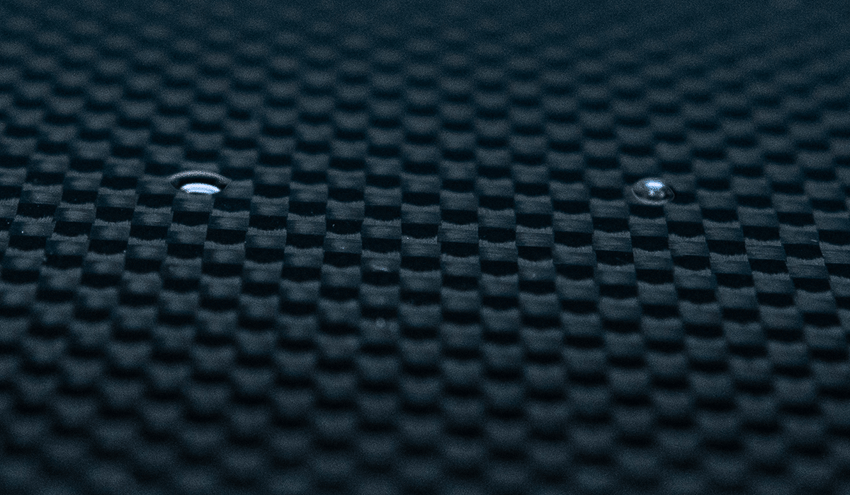

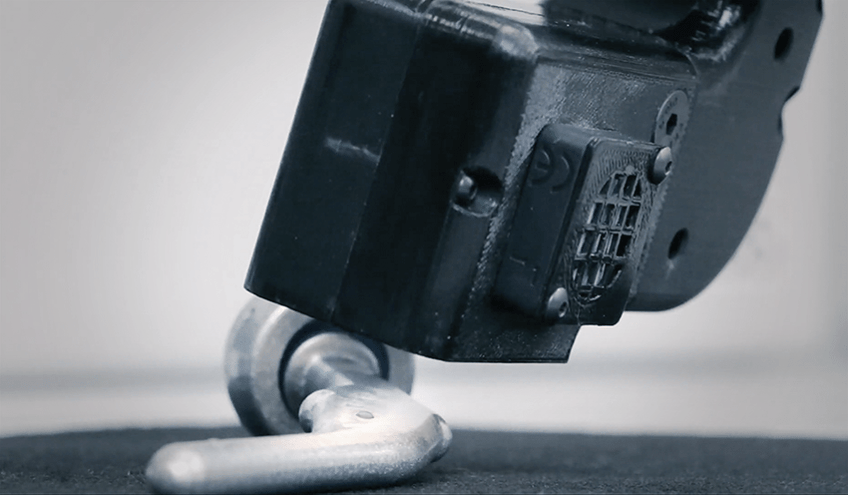

Brighton Science engineered its technology to adapt to any application directly on the factory floor. Patented Ballistic Deposition deposits a stream of micro-droplets on the surface; these micro-droplets contain kinetic energy, allowing the drops to overcome various textures and angles without interfering with measurement accuracy. The drop size can also be adjusted to take measurements on any sized surface, from a giant wind turbine to a minuscule medical catheter.

Here are just a few examples of Surface Analyst measurements on diverse surfaces right on the factory floor:

Round: Golf balls before printing or coating

Concave: Interior of automotive headlights before anti-fog coating application

Convex: Silkscreen plastic bottles post-flame treatment

Rough: Grit-blasted automotive parts

Smooth: Glass before frame sealing or coating

Reflective: Reflective laminates post-corona treatment

Vertical: Mechanical fasteners on aerospace exteriors

Upside down: Ship hulls before painting

Small: Circuit boards before conformal coating application

Get hands-on with your surface cleanliness with the Surface Analyst 5001.

So whether the measurement surface is highly textured, oddly shaped, or difficult to reach, the Surface Analyst can measure its surface cleanliness. This allows manufacturers to monitor and verify surface treatments right on the factory floor.

Read the free eBook to learn how you can implement contact angle measurements in your operations: What is Contact Angle? Bridging the Gap: How Contact Angle Insights Drive Manufacturing & Supply Chain Insights.