The building industry relies heavily on adhesives and coatings to ensure structures are weatherproof, durable, and aesthetically pleasing. From modern flooring to sturdy roofs, these building materials rely on a strong bond – both literally and figuratively.

However, unlike many other industries, building material manufacturers face a unique challenge: their product's success hinges not just on their own production line but also on proper installation. Defects or inconsistencies can lead to costly returns, dissatisfied customers, and even potential insurance claims. This is especially true given the construction industry's cautious nature when adopting new technologies.

The key to overcoming this challenge lies in gaining control of what you can control – the product itself. Manufacturers need a way to guarantee, with data-driven certainty, that their materials will meet industry standards and withstand everyday use's wear and tear. This is where predictive data comes in. By analyzing data collected at critical points in the adhesion process, manufacturers can gain a powerful, predictive understanding of how their products will perform on the job site.

The Silent Partners of Building Materials

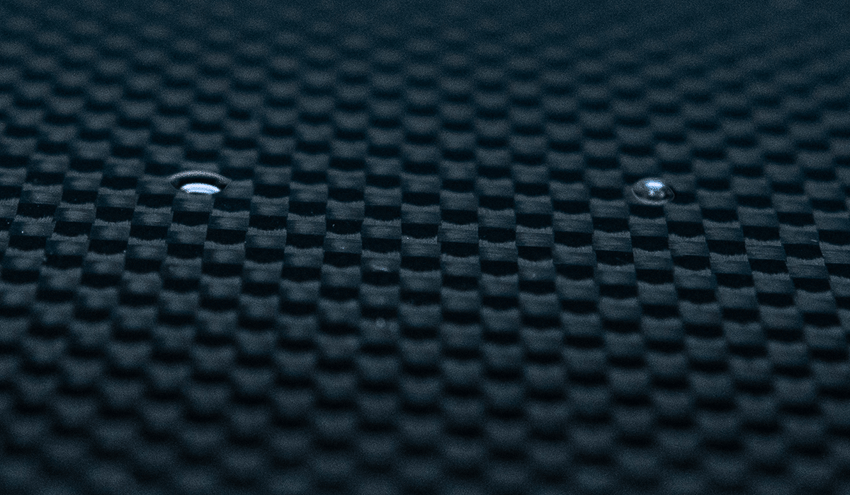

Nearly every aspect of building construction relies on the unseen heroes: adhesives and coatings, from the roof overhead to the floor beneath your feet. These polymeric coatings and resins play a critical role, often unnoticed, in ensuring a building's structural integrity and weather resistance.

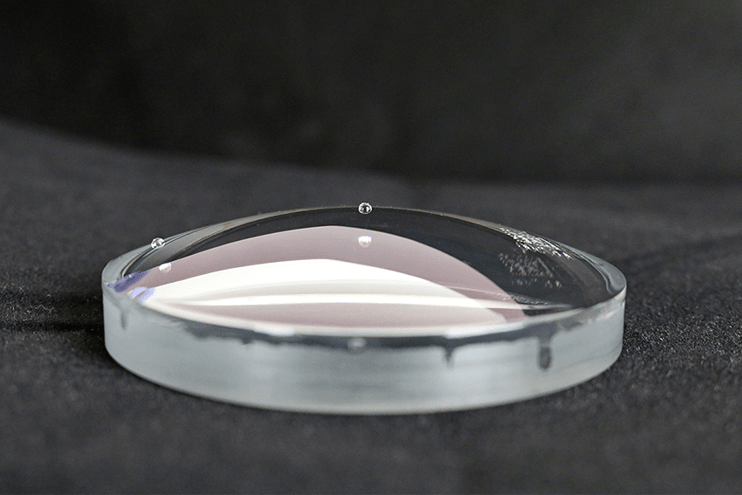

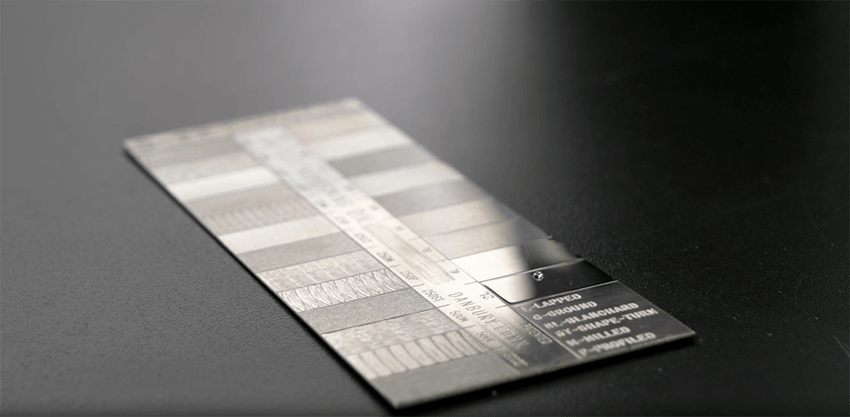

A crucial example is the hydrophobic coating applied to building sheathing – the hidden layer that forms the foundation for walls, roofs, and floors. While it may go unnoticed, the quality of this coating significantly impacts the building's overall performance. Manufacturers need a way to understand how these coatings affect adhesion – the key to a watertight exterior and a sound structure.

Moving Beyond Scrap-Heavy Testing

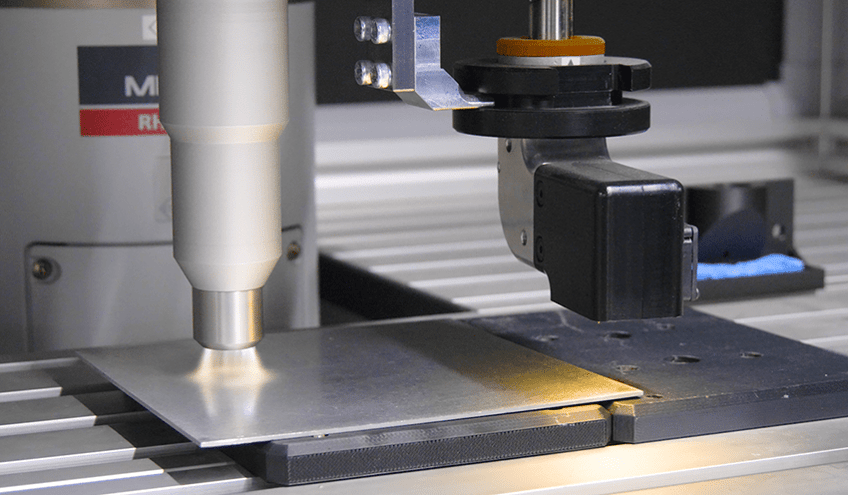

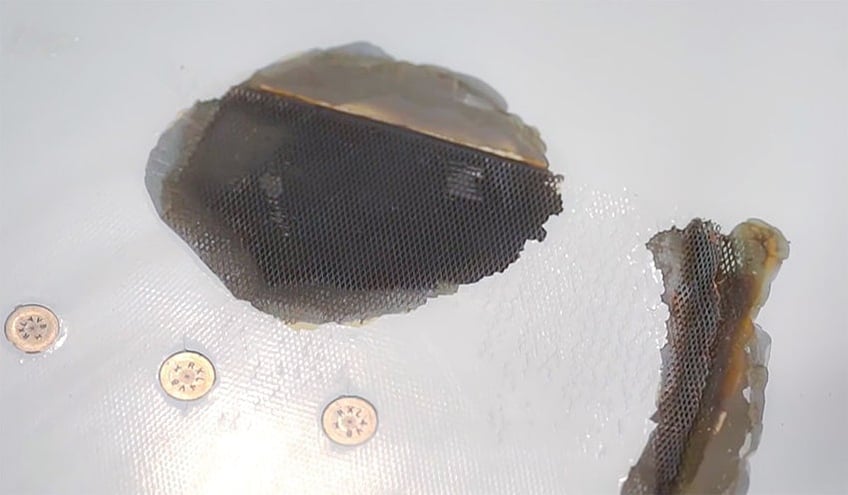

Traditionally, manufacturers rely on performance tests that generate significant scrap material and take a long time to complete. This approach simply isn't efficient for large-scale production.

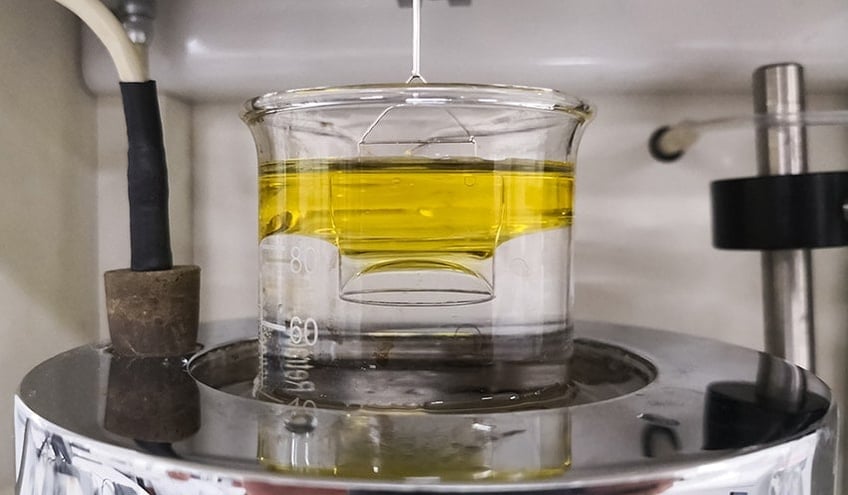

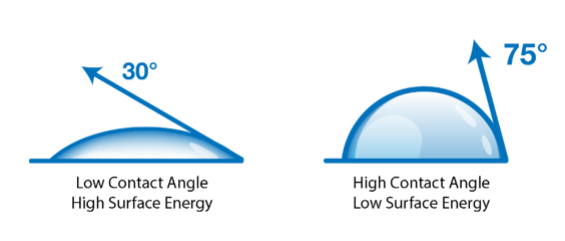

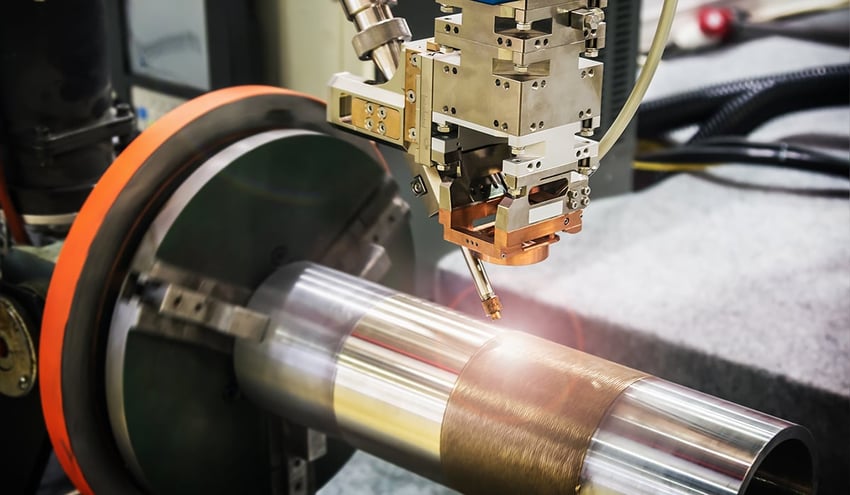

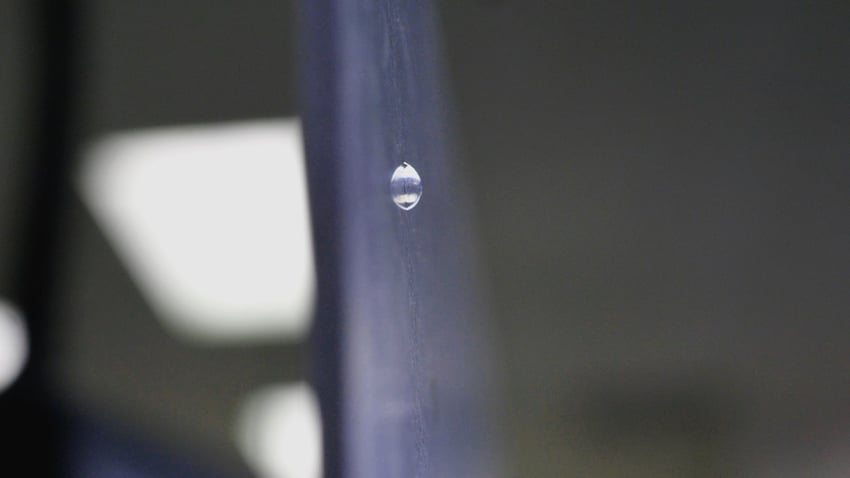

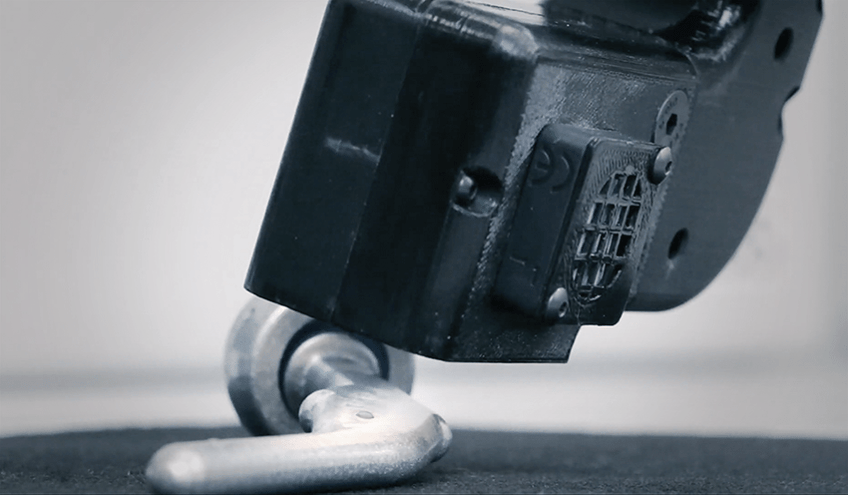

The answer lies in a new approach: predictive data through water contact angle measurement. This simple, quantitative test replaces time-consuming performance tests. Here's how it works:

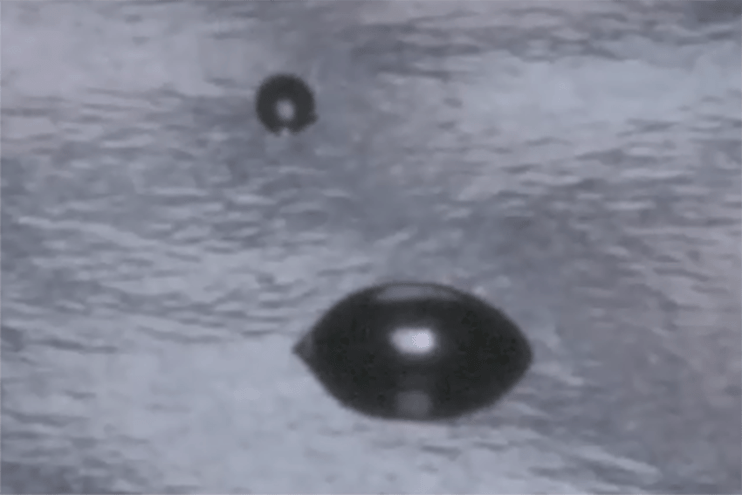

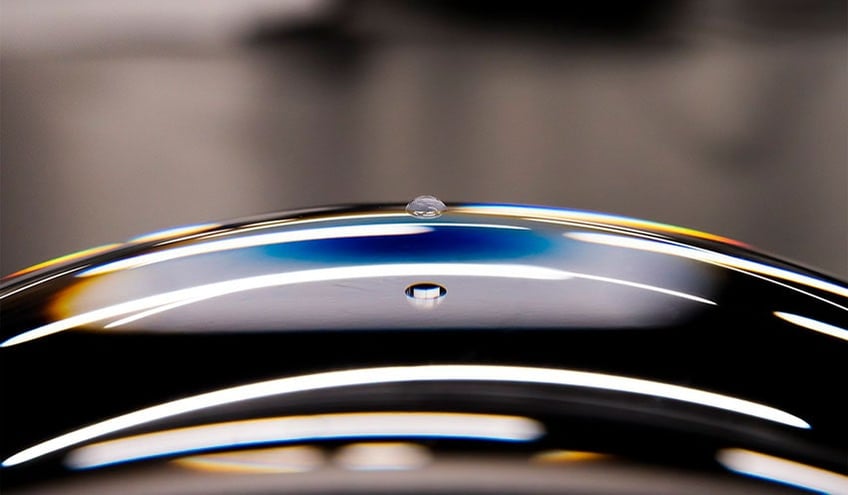

- A tiny drop of water is placed on the coated surface.

- The angle at which the water droplet rests on the surface reveals the surface's hydrophobicity (water repellency).

- This angle provides manufacturers with a wealth of information about how well the surface will bond with adhesives later in construction.

Building Confidence, One Measurement at a Time

The same water contact angle measurement can be used to test flashing tape adhesion and ensure a strong seal against moisture intrusion. By implementing this predictive approach, manufacturers gain several key advantages:

- Conclusive Data: Water contact angle measurements provide objective data to replace guesswork.

- Process Control: Manufacturers can monitor surface characteristics throughout production, eliminating inconsistencies.

- 100% Inspection: Fast and reliable measurements allow for testing of all materials, ensuring only high-performing products reach the market.

Predictive data empowers building material manufacturers to move beyond hope and into a world of certainty. By understanding how their products will perform on the job site, they can build trust with contractors and deliver superior building materials that stand the test of time.

Revolutionize Your Manufacturing with Surface Quality Inspection Technology.

Take Control of Your Adhesion Process

Are you ready to learn more about leveraging surface quality control for optimal adhesion? Download our free eBook, What is Contact Angle? Bridging the Gap: How Contact Angle Insights Drive Manufacturing & Supply Chain Insights.