So far, in our Guess the Contact Angle Series, we have brought you two videos: the first one shows the Surface Analyst taking a contact angle measurement on a piece of aged, 'as is' aluminum. The second video asks you to guess the contact angle after we took the same piece of aluminum but cleaned it using an IPA wipe.

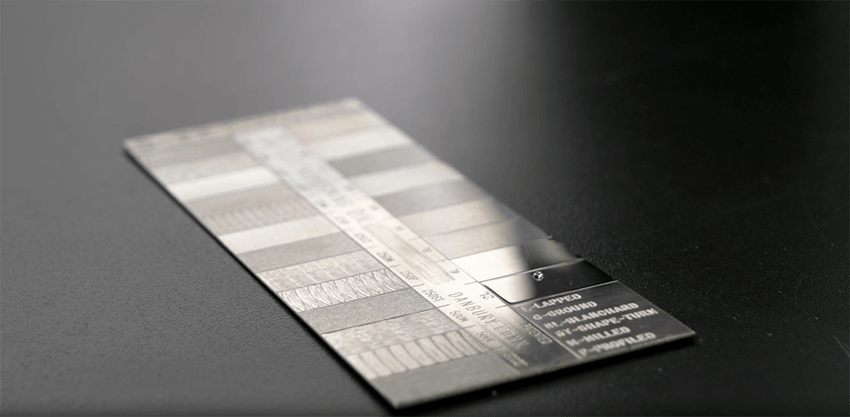

Today, we bring you a new video that demonstrates how contact angle changes (surface quality) when we take the same aluminum sample, clean it and abrade it.

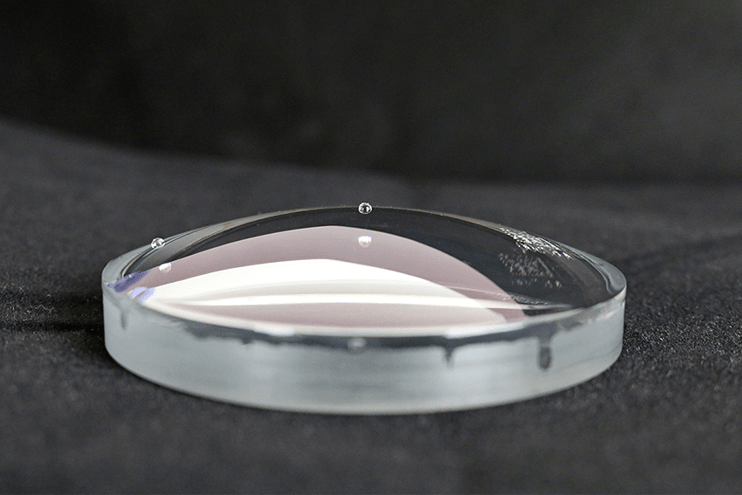

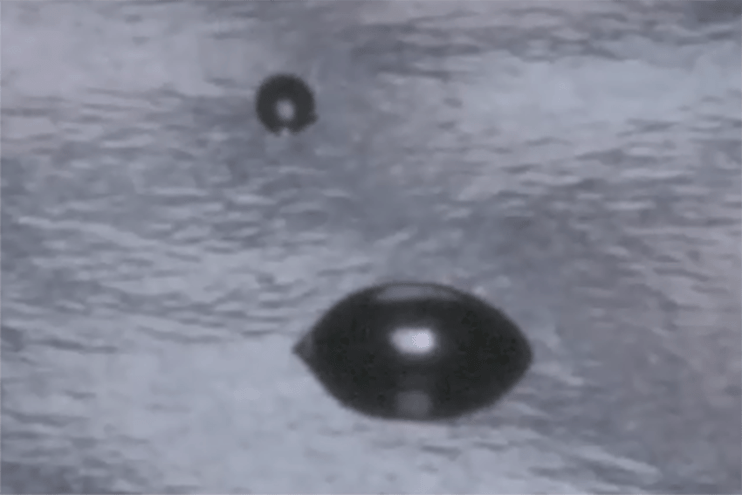

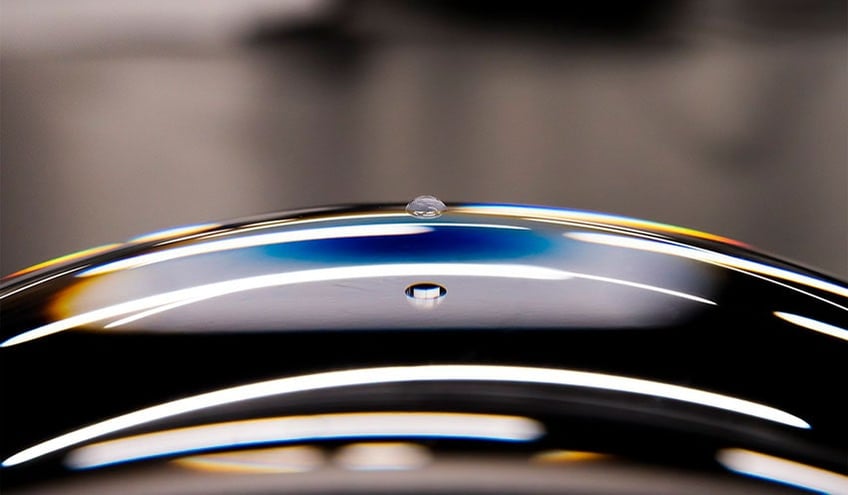

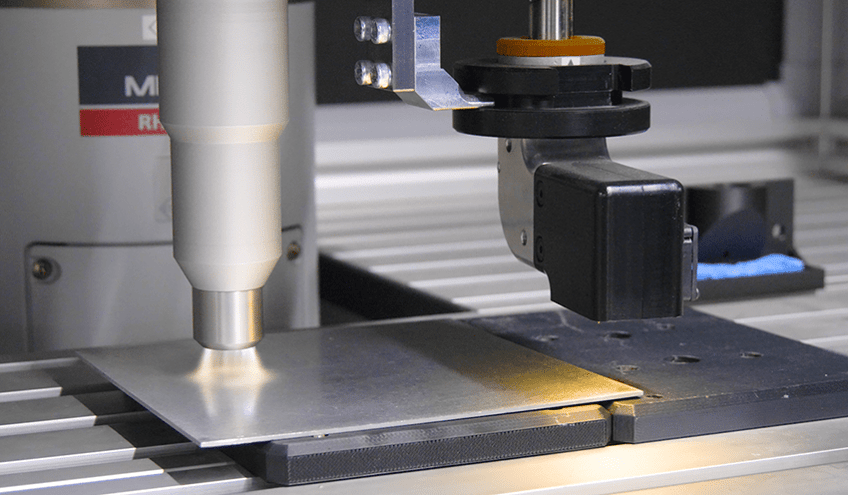

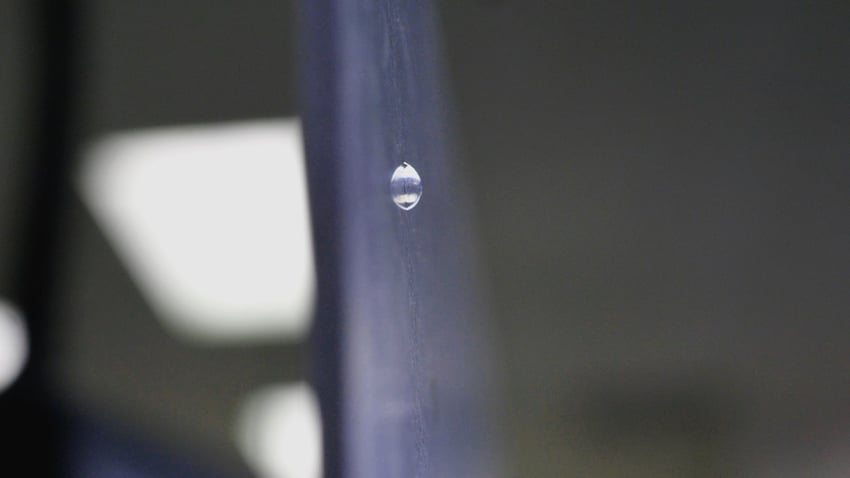

The contact angle featured in this demo is formed by a water droplet deposited using the Surface Analyst 5001 on a piece of aluminum with a smooth surface that has been cleaned using a manual IPA wipe and then hand-abraded with sandpaper.

Can You Guess the Contact Angle?

Contact Angle Answer

Have you recorded your guess? Click on the video link below to reveal the answer.

How did you do?

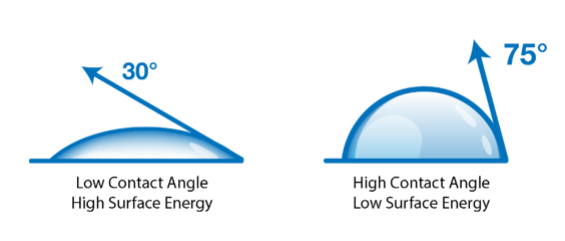

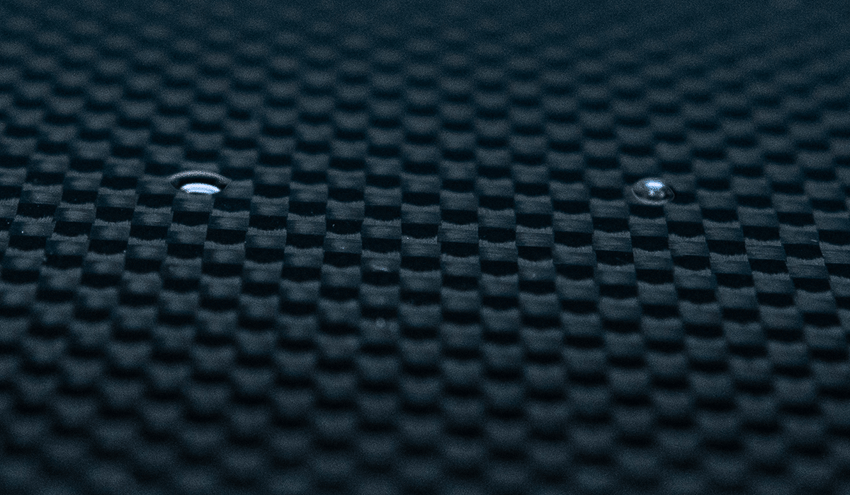

Keep in mind this was primarily a learning exercise, and remember that there is no single “best” value for a contact angle. The ideal water contact angle measurement will depend on your particular process and application.

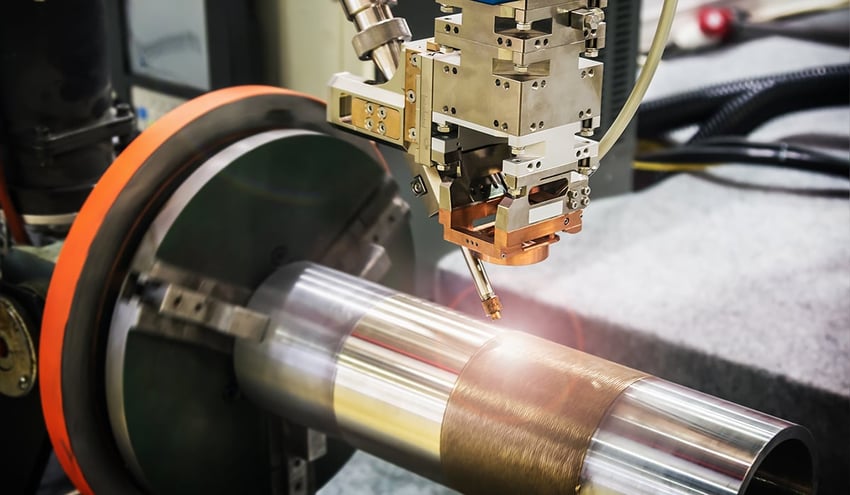

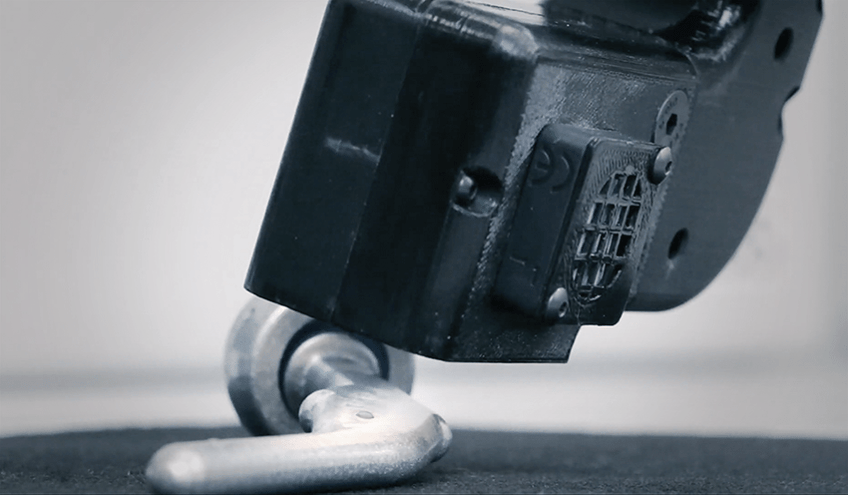

Get hands-on with your surface cleanliness with the Surface Analyst 5001.

Adhesion is a critical manufacturing process. The Surface Analyst line of products leverages our deep experience in surface engineering and materials science to validate any surface for cleanliness and guarantee reliable adhesion.

Download our free eBook, “What is Contact Angle?" to see your adhesion process through new eyes. Learn how to predict the future through easy and rapid contact angle measurements.