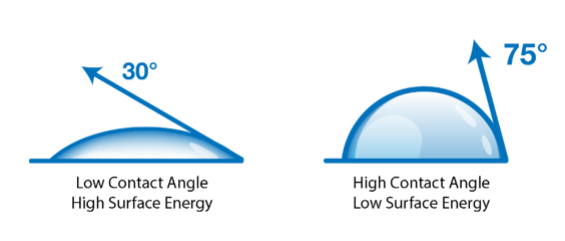

Have you wondered why some paints or coatings adhere effortlessly while others leave blisters or bubbles? The answer lies in wettability, the intricate dance between a liquid and a surface governed by a powerful principle known as contact angle. And measuring this microscopic tango? That's where the contact angle goniometer steps in.

In this article, we'll explore this instrument's applications and limitations, equipping you with the knowledge to navigate the world of contact angle measurements confidently.

What is a Contact Angle Goniometer, and How Does it Work?

Contact angle goniometry is the study of the characterization of liquid/solid interactions. It is a powerful tool in the field of surface science that measures the contact angle between a liquid droplet and a solid surface. This angle provides valuable information about the wettability and surface tension of the material being tested, making it a crucial parameter in various scientific and industrial applications.

The first benchtop goniometer designed at the NRL (U.S. Naval Research Laboratory) served as a monumental advance with a way to measure contact angles to measure surface energy.

To read about the differences between surface free energy and surface energy, read this article “What is the Difference Between Surface Free Energy and Surface Energy?”

A contact angle goniometer utilizes advanced imaging techniques and precise measurements to accurately determine the contact angle. There are multiple measurement methods that can be carried out by a benchtop goniometer. Common types include:

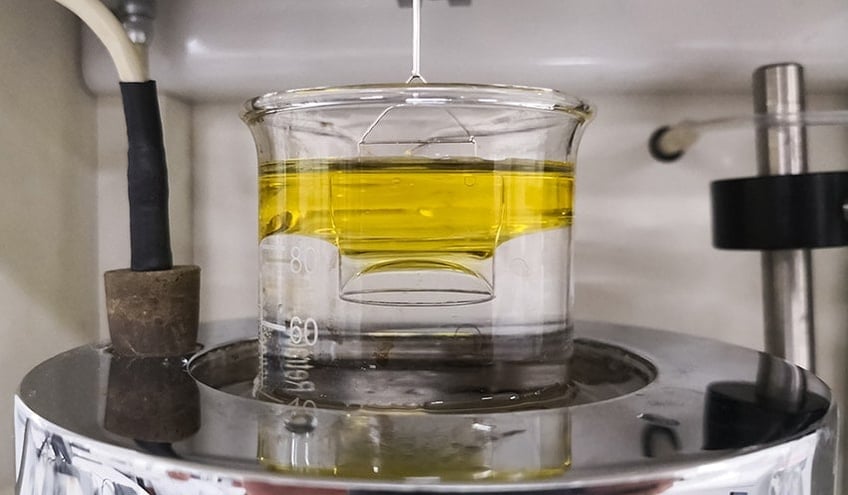

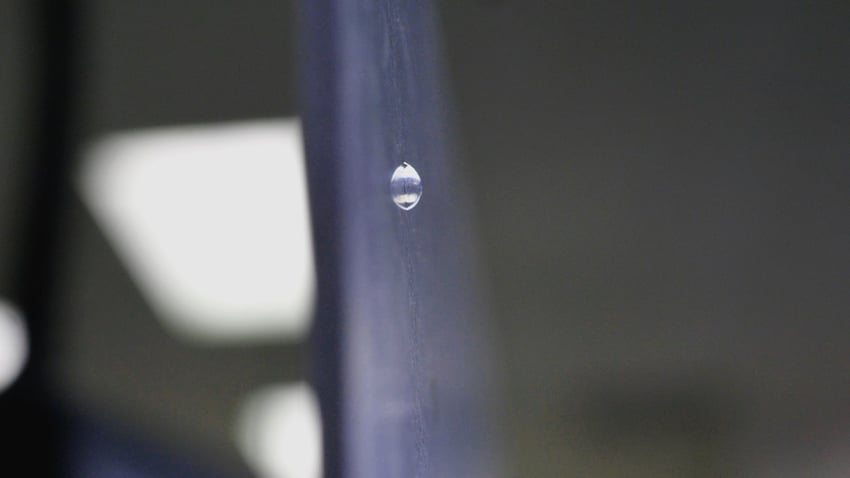

Sessile Drop Method: This is a fundamental method in which a droplet is placed on a surface, and the angle between the droplet and the surface is measured. This provides the static contact angle, which indicates the surface's wettability.

Advancing and Receding Contact Angle: sometimes referred to as “dynamic contact angle,” the contact angle is measured while the droplet is growing (advancing) or shrinking (receding) on the surface. This reveals contact angle hysteresis, which reflects the energy barrier for spreading and retraction and provides insights into surface heterogeneity.

What are the Common Applications of a Contact Angle Goniometer in Surface Science?

Today, more and more companies are realizing the need for material surface quality control, as the use of bonding is replacing mechanical fastening within manufacturing. In order to reliably bond, surface cleanliness is necessary. Therefore, measuring surface energy is important in industrial bonding, coating, sealing, printing, painting, or cleaning.

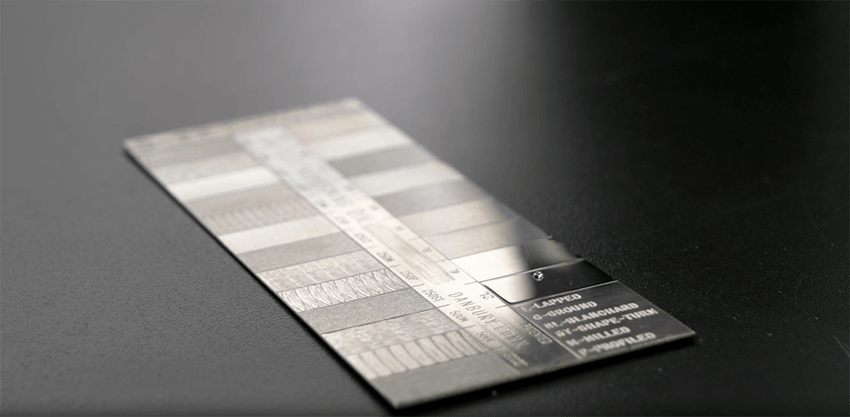

Adhesion Process Optimization: measuring the wettability of surfaces to optimize the way coatings, adhesives, print, and paints adhere for uniformity and functionality.

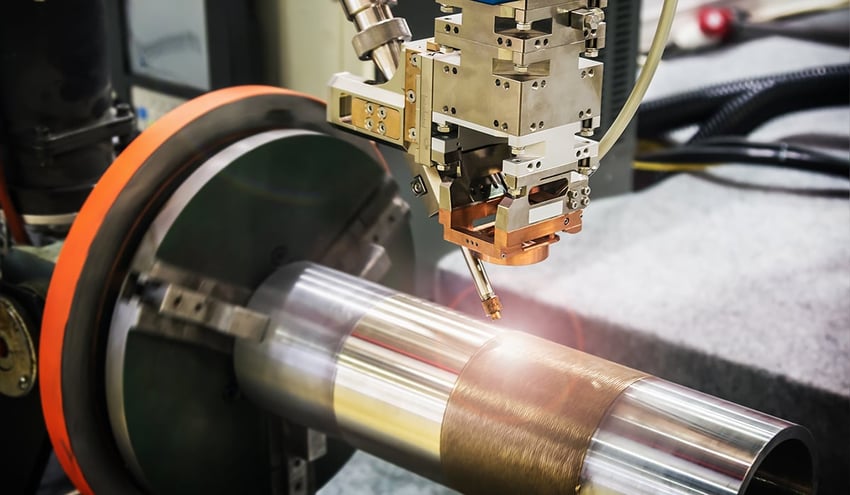

Surface Modification: evaluating the effectiveness of surface treatments like plasma treatment, chemical etching, flame treatment, and more.

Characterization of New Materials: understanding the surface properties of materials to predict their behavior during adhesion processes.

However, the standard benchtop goniometer has its limitations, rendering it less than ideal in a manufacturing setting where surface preparation is key to bonding and adhesion.

Limitations of the Benchtop Goniometer in Manufacturing

Benchtop goniometers, while suitable for controlled laboratory environments, present several significant limitations for measuring surface energy in manufacturing settings:

1. Restricted Geometry:

-

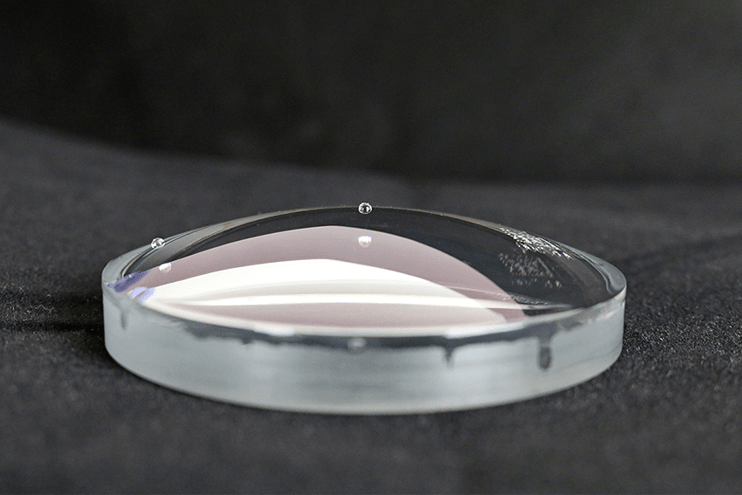

Benchtop goniometers typically accommodate small, flat samples, limiting their applicability to manufactured parts with complex shapes, curves, or rough surfaces.

-

Measuring contact angles on non-planar surfaces introduces complexities in droplet positioning and contact angle interpretation, affecting accuracy and reproducibility.

2. Manual Droplet Deposition:

-

The syringe-deposition method is prone to operator variability and inconsistent droplet size, impacting contact angle measurement results.

-

Controlled dispensing systems on automated goniometers can mitigate this, but they will still struggle with complex geometries.

3. Subjective Contact Angle Measurement:

-

Visual measurement of contact angle from a horizontal profile introduces observer bias and uncertainty, especially for low-contrast liquids or rough surfaces.

-

Automated goniometers with image analysis software improve accuracy and reduce subjectivity, but their sensitivity to environmental factors and surface heterogeneity remains.

4. Environmental Sensitivity:

-

The accuracy of contact angles taken on a benchtop goniometer relies on a controlled environment like a laboratory. Variable conditions often found on a production floor can significantly impact the reliability of measurements.

5. Speed and Throughput:

-

The manual nature of benchtop goniometer measurement limits their throughput and suitability for high-volume manufacturing lines.

6. Operator Skill and Training:

-

Accurately using benchtop goniometers requires training and experience in interpreting contact angles and handling the instrument.

-

This can be a bottleneck in production settings, and operator errors can introduce additional variability.

While benchtop goniometers remain valuable tools for controlled laboratory settings, their limitations in geometry, deposition technique, measurement subjectivity, environmental sensitivity, and throughput render them less suitable for the demands of real-world manufacturing environments. Alternative measurement techniques with higher accuracy, reproducibility, and adaptability to complex geometries are more appropriate for measuring surface energy on the production floor.

Benchtop Goniometer Alternative

From aerospace to auto parts, the Surface Analyst™ has dominated industries where quality depends on optimal adhesion. This portable contact angle meter empowers manufacturers to eliminate guesswork and optimize product performance.

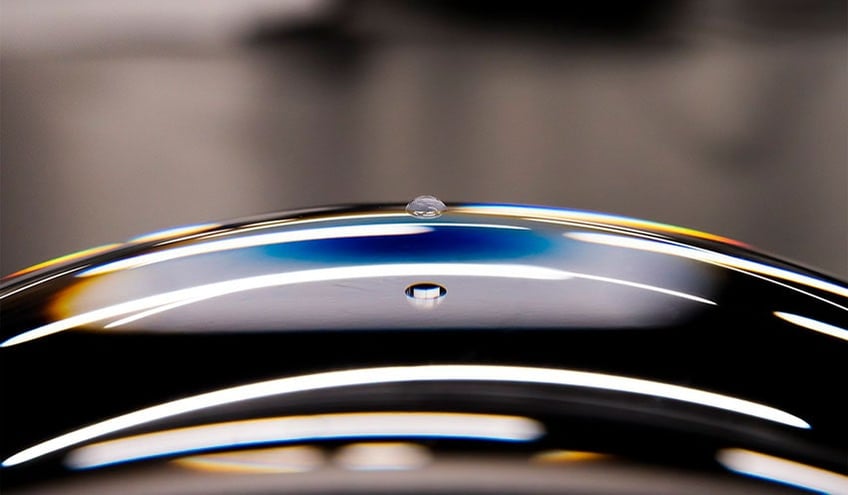

The Surface Analyst is more than just a clever handheld goniometer; it's a paradigm shift in contact angle analysis. By combining portability, multi-angle versatility, and the power of the patented Ballistic Deposition process, the Surface Analyst empowers you to reimagine the possibilities of surface characterization.

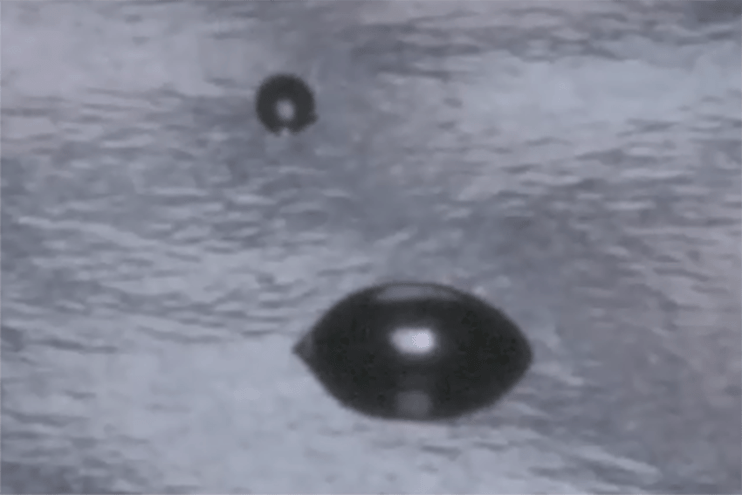

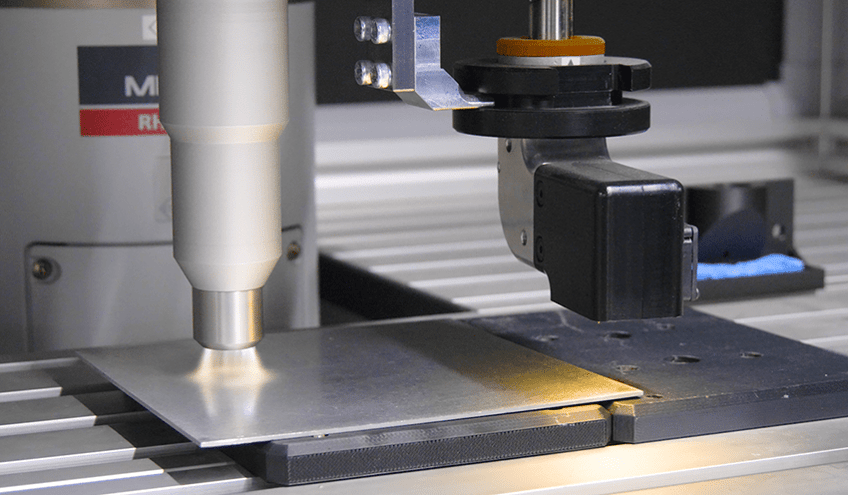

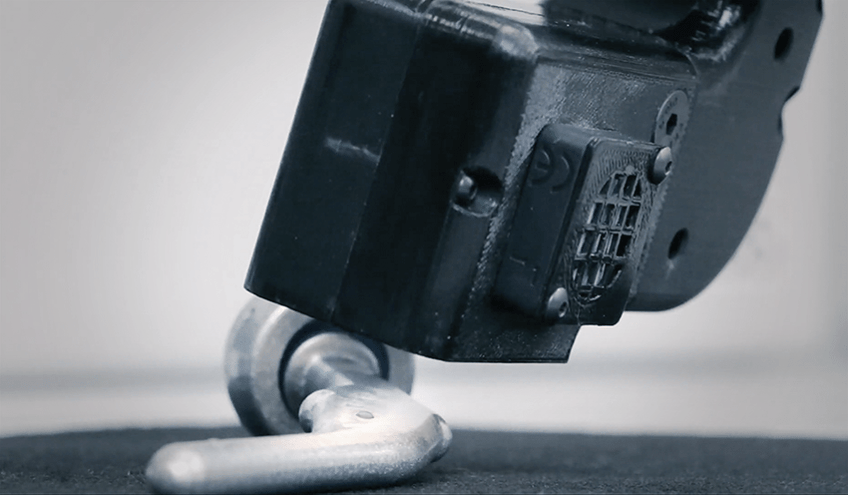

Unlike a benchtop goniometer, the Surface Analyst takes measurements vertically--rather than horizontally--using a patented process called Ballistic Deposition. The instrument deposits a stream of micro-drops that coalesce on the surface. The kinetic energy generated by this deposition allows the drop to spread out over the surface with little to no interference from rough surfaces. Because of Ballistic Deposition, measurements can also be taken at different angles and in hard-to-reach places.

The introduction of BConnect has connected this powerful Surface Analyst technology into a cloud-based solution that creates Surface Intelligence Networks for quality teams, plant managers, field service, and supply chain managers. This subscription-based solution eliminates the costs of equipment ownership and eliminates downtime for device calibration and servicing.

A Comparison of Goniometers

Unlike a benchtop goniometer, which requires extensive training and a skilled operator, the Surface Analyst can be easily mastered in just a few minutes. Moreover, its measurements are objective, making it suitable for use by personnel of different skill levels within a company.

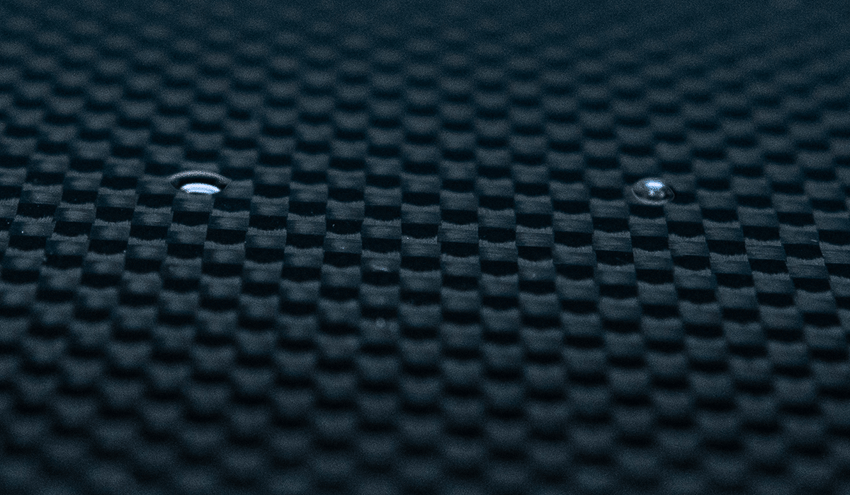

In an outside study comparing the Surface Analyst with two other goniometers, the Surface Analyst showed more consistency and accuracy. This result is due to the Surface Analyst's ability to Ballistically Deposit water droplets on the surface. The inconsistencies in the other goniometers are most likely due to surface roughness. Because a syringe drops these liquids, they lack the kinetic energy of a ballistically deposited drop, and they lose the ability to accurately measure surfaces that are rough.

The benchtop goniometer is an invaluable instrument for measuring surface energy under controlled laboratory settings. Brighton Science's Surface Analyst combined with BConect offers a solution for precise repeatability and a powerful Surface Intelligence Network that enables organizations to unlock a new dimension of productivity, as well as explore powerful changes in their product and service model.

Read the technical paper featuring the comparison between the Surface Analyst and a benchtop goniometer. This paper displays engaging data and thorough analysis by Brighton Science's Chief Scientist, Dr. Giles Dillingham.

Download the eBook “What is Contact Angle? Bridging the Gap: How Contact Angle Insights Drive Manufacturing and Supply Chain Innovations" to learn how your business can use contact angle measurements to ensure quality-driven surface preparation.