Key Takeaways

- The reliability of formed-in-place gaskets (FIPG) depends heavily on surface cleanliness before sealant application.

- Automotive manufacturers often struggle to verify and control industrial parts washer performance, creating risks for leaks, failures, and costly rework.

- Objective surface cleanliness data, including contact angle measurements, enables manufacturers to optimize wash settings and confidently prepare parts for FIPG bonding.

- Implementing a data-driven cleaning strategy reduces field failures, strengthens FIPG bond integrity, and improves process efficiency.

- Brighton Science technology equips teams to quantify cleanliness, eliminate guesswork, and build reliable, repeatable adhesion processes.

Competition is hot in the fast-paced automotive industry, and manufacturers work intensively to create more efficient, reliable vehicles. When the race is head-to-head, there is no room for failure. Finding ways to avoid failures and produce a more reliable vehicle provides a competitive edge.

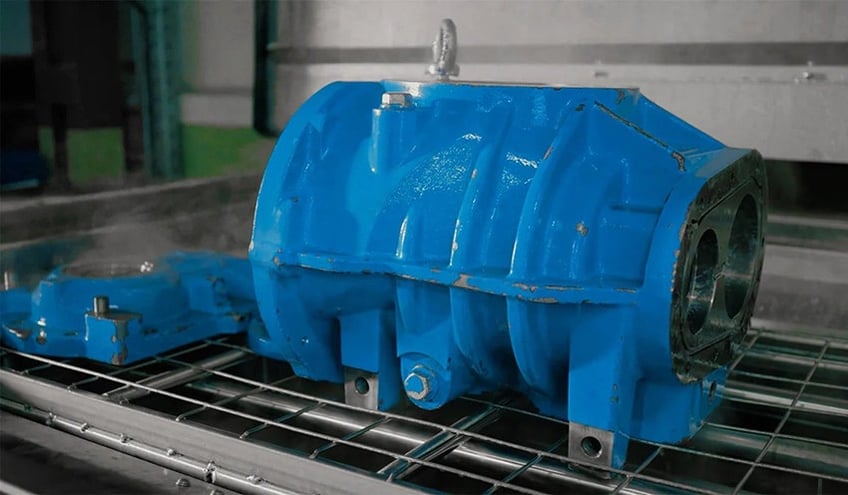

New technologies such as FIPG (formed-in-place gaskets), which contribute to a more efficient, reliable system, can provide that needed edge. As a replacement for traditional gaskets such as cork and rubber, FIPG sealant is stronger and more reliable. An adhesive applied directly on the factory floor, FIPG increases efficiency and reduces waste. The adhesive also makes a stronger seal than traditional gaskets and can tolerate more wear, so failure rates decline significantly. However, with this new technology comes new specifications and assembly processes.

The integrity of FIPG relies on the surface cleanliness of the part before sealing. The part’s surface must be clean and clear of chemical contaminants to maintain a strong seal and avoid failures. In the past, cleanliness in the automotive industry only presented a concern with moving mechanics, so grit and dirt were the primary threats. But, when applying FIPG, contaminants can be more than grit and dirt; various assembly liquids—mold releases, detergents, cutting fluids—exist in the manufacturing processes and can derail this imperative bond.

Rethink your adhesion manufacturing processes with Surface Intelligence.

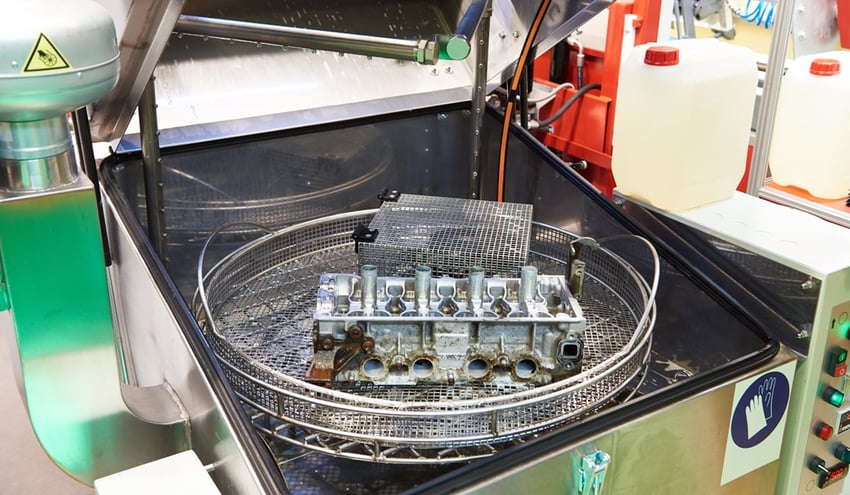

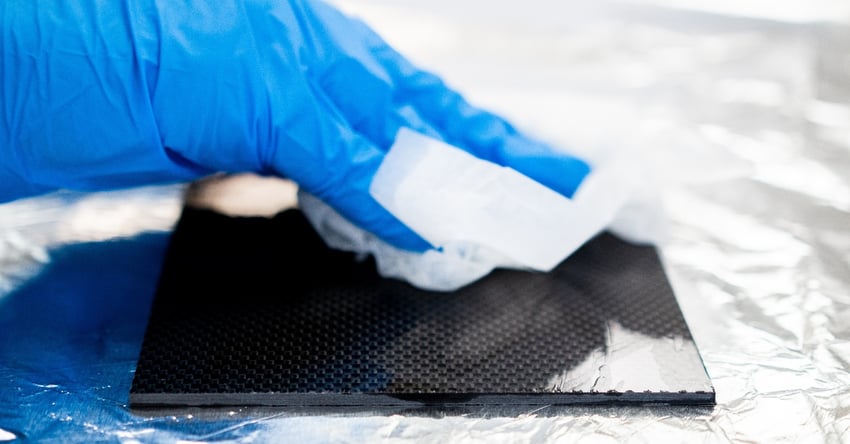

Several cleaning processes, such as parts washers and solvent wipes, are used to clean surfaces in the automotive industry; however, without a way to monitor and verify these cleaning processes, the level of surface cleanliness remains unknown.

From Chance to Science: How One Engine Block Manufacturer Achieved Optimal Cleaning for FIPG Bonding

This case study details the journey of an engine block manufacturer who transformed their cleaning process from a chance-based system to a data-driven approach. The manufacturer, a supplier to one of the "Big Three" US automakers, relied on field failures to assess the effectiveness of their industrial parts washer. This reactive approach lacked control and risked costly product failures.

The Challenge:

- Lack of a reliable method to verify cleaning efficacy before FIPG application, leading to potential bond failures.

- Absence of objective data to ensure consistent cleanliness across engine block surfaces for optimal FIPG adhesion.

- Difficulty in optimizing cleaning protocols for efficiency and cost-effectiveness.

The Solution:

Brighton Science's surface science expertise, plus innovative technology, provided the missing piece. This solution allowed the manufacturer to:

- Quantify Cleaning Performance: Analyze the impact of different wash variables (duration, solvent type) on surface cleanliness.

- Optimize Cleaning Protocols: The manufacturer identified the ideal wash settings for consistent, optimal cleaning by analyzing contact angle measurements across multiple areas on an engine block.

- Ensure FIPG Bond Integrity: Precise cleanliness data allowed for confident FIPG application, minimizing the risk of leaks and seal failures.

The Outcome:

By replacing guesswork with data-driven cleaning processes, the engine block manufacturer achieved:

- Reduced Field Failures: Proactive monitoring and control of cleaning variables prevented defective products from reaching customers.

- Enhanced FIPG Bond Reliability: Objective data ensured optimal surface preparation for FIPG application, leading to superior bond strength and performance.

- Improved Process Efficiency: Data-driven optimization led to reduced costs for cleaning agents and wash cycle times.

By focusing quality efforts on controlling surface cleanliness and transitioning to a data-driven approach, this automotive manufacturer achieved reliable FIPG bonding, minimized waste, and delivered a consistently high-quality product to their customers.

To learn how to control surface cleanliness for successful FIPG applications, download the eBook "Metrics That Matter: Quantifying Cleaning Efficacy for Manufacturing Performance."

FAQ: Optimizing Parts Washer Efficiency for FIPG

Why is surface cleanliness so important for FIPG applications?

FIPG sealants require a chemically clean surface to create a reliable bond. Even small amounts of mold release, cutting fluid, detergent, or residue from upstream steps can weaken adhesion and lead to gasket failure.

What contaminants are most common before FIPG bonding?

Beyond visible dirt or grit, manufacturers often encounter invisible or thin-film residues from machining fluids, additives, cleaners, and corrosion inhibitors. These contaminants interfere with the molecular interactions needed for a strong FIPG seal.

Why are traditional parts washers not enough on their own?

Parts washers and solvent wipes remove some contaminants, but without verification tools, manufacturers cannot confirm whether the surface is truly ready for FIPG. This creates a gap between intended cleaning performance and actual cleanliness on the line.

How does data-driven cleanliness measurement improve FIPG reliability?

By quantifying contact angle values at multiple locations on a part, teams can understand how wash duration, chemistry, nozzle coverage, and maintenance cycles influence cleanliness. This enables controlled, repeatable preparation rather than reactive troubleshooting.

What benefits did the engine block manufacturer see from using Brighton Science technology?

They reduced field failures, strengthened bond consistency, cut down on wash cycle time and chemistry usage, and replaced subjective visual checks with precise cleanliness data that supported continuous improvement.

Can this approach help optimize costs as well as quality?

Yes. Data-driven optimization often reduces chemical consumption, energy use, cycle time, and scrap. It also prevents expensive warranty returns by ensuring the FIPG bond is reliable from the start.

Where can I learn more about measuring and controlling cleaning performance?

Download the eBook Metrics That Matter: Quantifying Cleaning Efficacy for Manufacturing Performance for a deeper look at how quantitative surface measurement drives reliable adhesion processes.