Key Takeaways

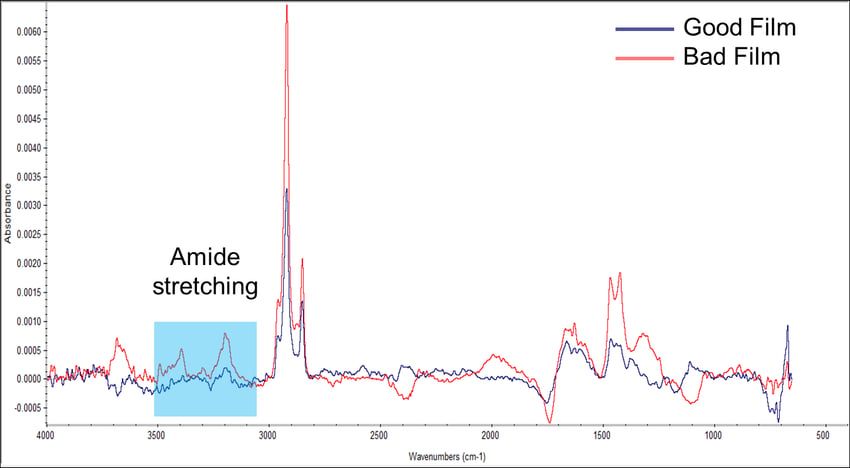

- A window and door manufacturer needed a more objective, non-destructive way to verify plasma treatment.

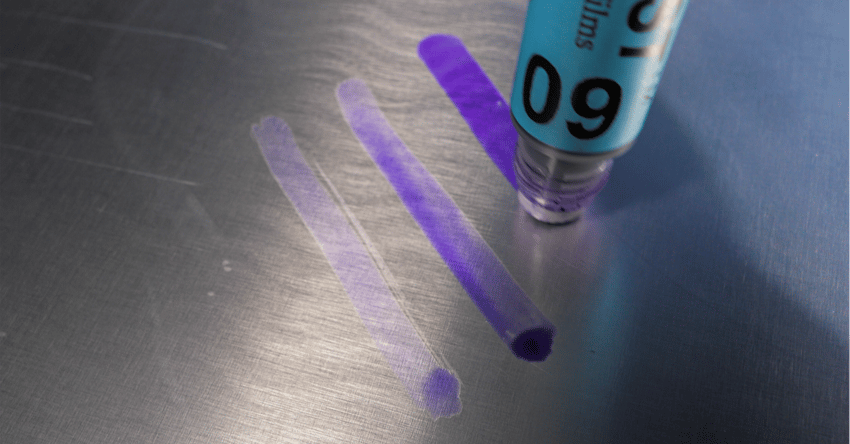

- Dyne inks created challenges due to mess, subjectivity, and part damage.

- Transitioning away from dyne required maintaining dyne-based language for suppliers and customers.

- The Surface Analyst™ enabled a measured, data-driven transition by reporting both dyne and contact angle values.

- Surface verification expanded beyond one step, improving overall process consistency.

The Challenge: Verifying Surface Treatment with Dyne Inks

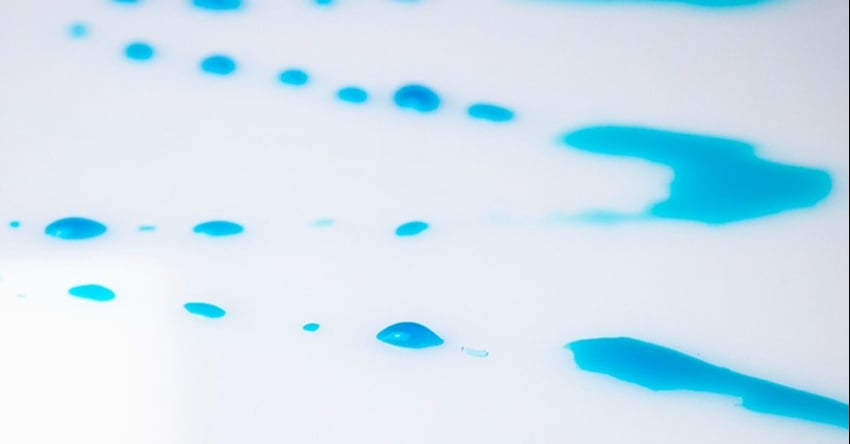

For window and door manufacturers, verifying surface treatment is a critical step in ensuring reliable bonding performance. Many manufacturers rely on dyne pens to verify plasma treatment on vinyl components prior to bonding.

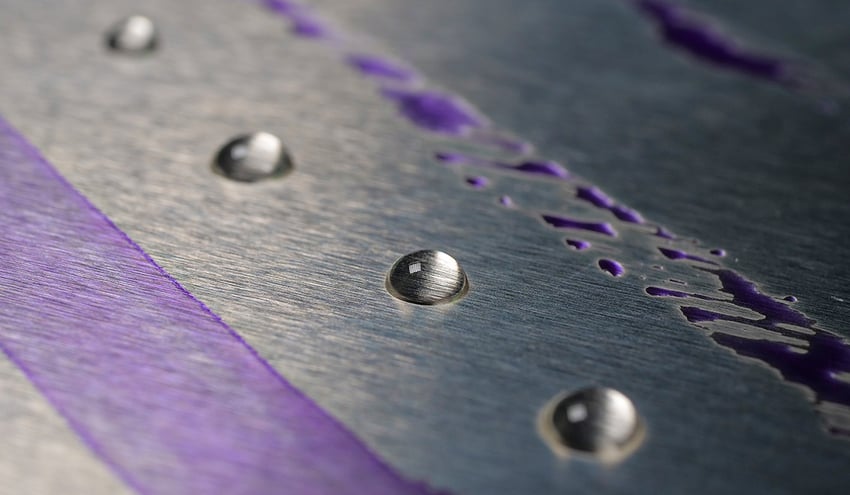

Over time, the limitations of dyne inks became increasingly problematic:

- Testing was messy and destructive to finished parts

- Results varied depending on operator technique

- Measurements were subjective, making it difficult to enforce consistent standards

- Documentation lacked the rigor needed for broader process control

These challenges prompted one manufacturer to look for a more reliable surface verification method—without disrupting existing supplier and customer expectations.

The Solution: Introducing the Surface Analyst Without Breaking the System

The manufacturer identified the Surface Analyst as a potential alternative. Unlike dyne inks, the Surface Analyst provides non-destructive, quantitative measurements of surface condition using contact angle analysis.

However, one key concern remained: Dyne values were the common language used across suppliers and customers.

To address this concern, the manufacturer worked closely with Brighton Science’s applications lab to correlate existing dyne specifications with quantitative contact angle measurements.

Through controlled testing and analysis, the lab helped establish equivalent contact angle targets that aligned with the manufacturer’s historical dyne-based requirements. This approach allowed the customer to:

- Preserve continuity with supplier and customer specifications

- Transition confidently to objective, contact angle–based measurements

- Move away from subjective dyne testing without disrupting production expectations

Importantly, this was a transitional effort, designed to support adoption and specification alignment, not an ongoing testing model. Once equivalency targets were established, the manufacturer was able to rely on repeatable, non-destructive contact angle measurements for routine surface verification.

Expanding Value Across the Manufacturing Process

Once implemented, the Surface Analyst was not limited to a single verification point. The manufacturer began using it to verify plasma treatment on additional plastic components within the window assembly process.

As a result, surface verification became:

- More efficient, reducing testing friction

- Fully quantitative, supporting clearer specifications

- Objective and repeatable, regardless of operator

- Easier to apply across multiple components and steps

This evolution helped the manufacturer move beyond simple pass/fail checks toward a more controlled, data-driven approach to surface quality.

Looking Ahead: From Measurement to Surface Intelligence

While this case focused on improving surface verification at the point of measurement, many manufacturers face a broader challenge:

How do you manage, compare, and scale surface data across lines, plants, and suppliers?

That’s where connected data platforms come into play.

Extend Surface Measurement with BConnect

Surface measurements are most powerful when they’re visible, comparable, and actionable.

BConnect is Brighton Science’s cloud-based platform designed to help manufacturers:

- Centralize surface measurement data

- Track trends across time, tools, and locations

- Support process validation and continuous improvement

- Share objective surface data across teams and facilities

If your team is moving beyond manual verification and toward standardized surface quality management, BConnect helps turn measurements into insight.

Optimize the power of next-gen connectivity with data & surface intelligence.

Frequently Asked Questions

Q: Why do manufacturers move away from dyne inks?

A: Dyne inks are subjective, messy, and destructive. Results can vary between operators, making them difficult to standardize for quality control.

Q: Is the Surface Analyst destructive to parts?

A: No. Unlike dyne inks, contact angle measurements are non-destructive, making them suitable for in-process verification.

Q: Does this case study imply the use of connected data platforms?

A: No. This customer focused on improving surface verification at the measurement level. Platforms like BConnect represent a next step for teams looking to scale and manage surface data more broadly.

Q: Where can I learn more about dyne testing alternatives?

A: Brighton Science offers an in-depth eBook: “What is Dyne Testing? Enhance Precision and Effectiveness with the Ultimate Alternative to Dyne Testing.”