Key Takeaways:

- Surfactants are chemical compounds that lower a liquid's surface tension, allowing it to spread and interact with solids more easily.

- They are essential ingredients in cleaners, coatings, adhesives, and inks, but residual surfactants left behind can contaminate surfaces and weaken bonds.

- Surface tension and surface energy determining whether liquids will wet or adhere property to a surface.

- Detecting and controlling residual surfactants is critical to achieving chemically clean, bondable surfaces.

- The most reliable way to identify surfactant contamination is through water contact angle (WCA) measurement, which quantifies surface readiness.

- BConnect enables manufacturers to measure, monitor, and manage surface energy and cleanliness directly on the production line for consistent adhesive performance.

Introduction

In manufacturing, controlling surface quality is one of the most reliable ways to ensure strong, durable adhesive bonds and high-quality coatings. Whether applying a sealant to an automotive engine block or printing ink on flexible packaging, success depends on understanding and managing surface tension and surface energy.

One of the most important, and sometimes problematic, tools in that process is the surfactant.

Surfactants are found almost everywhere in manufacturing: in cleaning solutions, paints, lubricants, adhesives, and even cosmetics. They make dissimilar substances, like oil and water, mix. They help detergents dissolve contaminants and make coatings spread evenly. But when left behind, they can cause more harm than good.

Residual surfactants are a common hidden contaminant responsible for poor adhesion, inconsistent coatings, and bond failures. Understanding how surfactants work, and how to detect when they’re present, is essential to achieving predictable manufacturing outcomes.

What is a Surfactant?

At its core, a surfactant (short for surface-active agent) is a compound that reduces a liquid’s surface tension. This reduction allows the liquid to spread more easily across a solid surface—a process called wetting.

In practice, surfactants are used to:

- Help cleaning agents remove oils and particulates.

- Ensure coatings and inks cover surfaces evenly.

- Improve adhesion between dissimilar materials.

A simple example is found in agriculture: insecticides often include surfactants so the liquid spreads uniformly across plant leaves rather than beading up.

Surfactants consist of molecules with two parts: a hydrophilic head (water-attracting) and a hydrophobic tail (water-repelling). This dual nature lets them position themselves at liquid–air or liquid–solid interfaces, where they can lower surface tension and alter wetting behavior.

Rethink your adhesion manufacturing processes with Surface Intelligence.

How Surfactants Reduce Surface Tension

Surface tension is a measure of how strongly liquid molecules attract one another. Liquids like water have high surface tension because of strong intermolecular forces.

When a surfactant is added, its molecules migrate to the liquid’s surface and form a layer where their hydrophobic ends face the air. This weakens the cohesive attraction between liquid molecules, reducing the energy needed to expand the surface.

Meanwhile, within the bulk of the liquid, surfactant molecules can cluster together to form micelles, tiny spherical structures that trap and dissolve oils and other hydrophobic contaminants.

These micelles are the reason detergents can remove substances that water alone cannot. The amount of surfactant required to reach this point is called the critical micelle concentration (CMC), the ideal balance where cleaning or coating performance is maximized without waste or interference.

The Role of Surfactants in Manufacturing

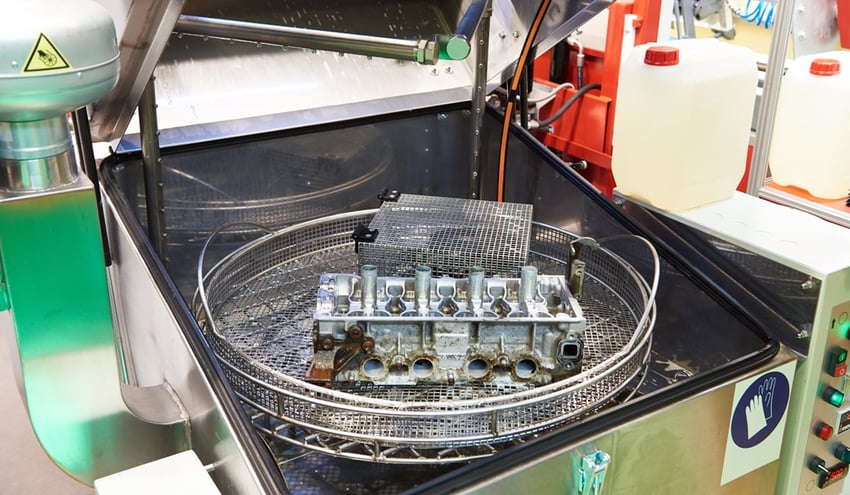

In production environments, surfactants are most commonly used in aqueous cleaning systems. They make it possible to remove oils, greases, and other contaminants from metal, plastic, or composite surfaces before bonding, painting, or coating.

However, if these surfactants are not completely rinsed away, they can remain on the part’s surface as an invisible film of low surface energy material, ironically becoming a new contaminant that inhibits adhesion.

A surface that appears clean to the naked eye may still have a molecular layer of surfactant that prevents adhesives or coatings from properly wetting and bonding.

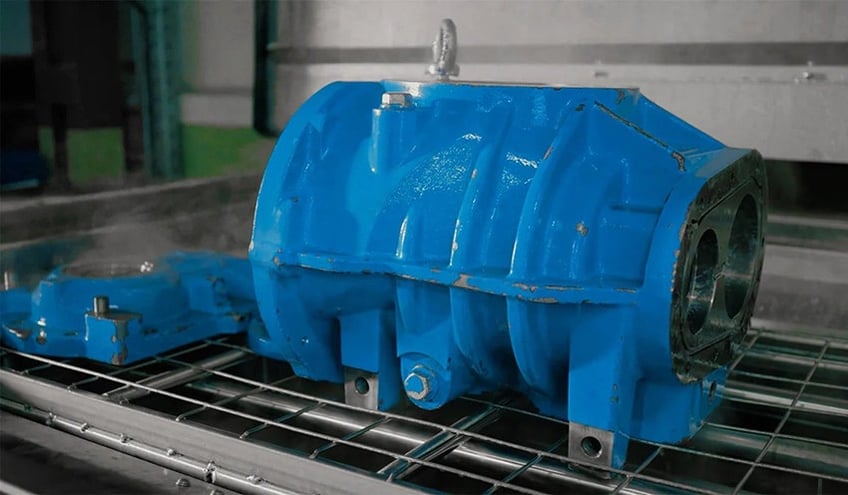

Example: Automotive Engine Sealing

In automotive manufacturing, silicone sealants are applied to engine blocks to prevent oil leaks. Even small amounts of residual surfactant left behind after aqueous cleaning can cause sealant adhesion failure, leading to leaks, warranty claims, and costly rework.

Surfactants help create clean surfaces, but if not controlled, they can just as easily compromise them.

How Surfactant Contamination Affects Surface Condition

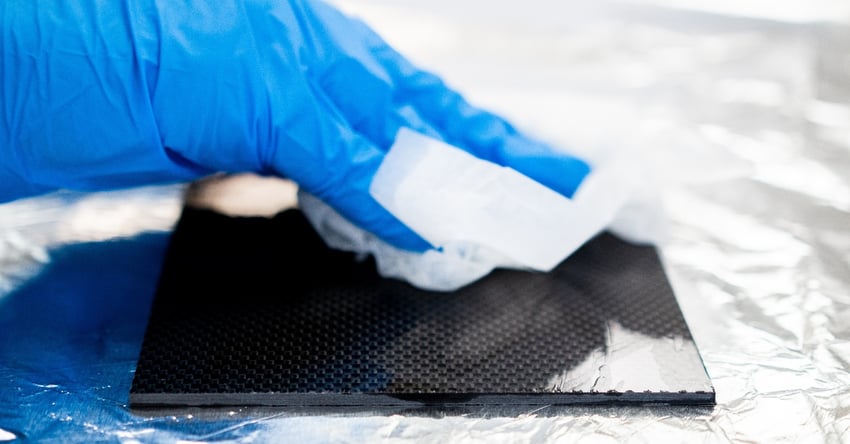

Surfactants lower surface tension—exactly what makes them so effective in cleaning and coating formulations. But when those same compounds remain on a surface that needs to bond or coat, their low surface energy properties block proper wetting.

This leads to:

- Coating defects (pinholes, fisheyes, or poor coverage)

- Weak adhesive bonds due to poor wetting

- Inconsistent seal performance and premature product failure

Manufacturers often struggle with this invisible residue because it’s not detectable by appearance or simple visual inspection.

Why Traditional Cleanliness Tests Fall Short

A common but highly subjective method for checking cleanliness is the water break test—pouring water over a surface to see if it “sheets off” uniformly.

In theory, uniform sheeting indicates a clean, high-energy surface. In practice, this test is unreliable. Some technicians even (unknowingly) spray surfactants on a surface to make the water sheet, giving the false impression of cleanliness. The result is a “passing” test that hides a contamination problem and sets the stage for adhesion failure.

Visual or subjective methods cannot quantify cleanliness. To achieve process verification, manufacturers need a measurable, repeatable test that accurately reflects a surface’s chemical state.

Water Contact Angle: The Best Indicator of Surface Cleanliness

The most direct and quantitative way to determine whether surfactant residues are present is through water contact angle (WCA) measurement.

When a drop of water is placed on a surface, the angle formed between the droplet’s edge and the surface provides a precise indicator of surface energy and cleanliness:

- Low contact angle: The water spreads out, indicating high surface energy and a clean, bondable

surface. - High contact angle: The water beads up, indicating low surface energy, often due to contamination from surfactants, oils, or processing residues.

If a water droplet continues to spread slowly after contact, this behavior suggests surfactant absorption—a clear sign that a thin surfactant film remains.

Because WCA directly measures the molecular interaction between a surface and water, it provides a quantitative, repeatable method for verifying surface readiness.

Modern Surface Intelligence platforms like BConnect automate water contact angle measurement and analysis. This allows teams to detect surfactant residues within seconds and ensure every surface meets adhesion or coating specifications before production continues.

From Detection to Process Control

Every stage in a manufacturing workflow where a surface changes through cleaning, treatment, or coating is a Critical Control Point (CCP). Monitoring each CCP ensures that surface quality is maintained and that no contaminants are introduced.

With BConnect, manufacturers can:

- Measure surface energy and cleanliness directly on the line.

- Identify surfactant contamination or other low energy films before they cause defects.

- Track process data across shifts, batches, and suppliers.

- Integrate Surface Intelligence with digital quality systems for traceability and continuous improvement.

By turning water contact angle measurements into real-time, connected data, BConnect transforms surface quality from a variable into a controllable, verified process parameter.

Why Controlling Surfactants Matters

Surfactants are indispensable to modern manufacturing, but their behavior must be understood and controlled.

- When used properly in cleaning or coating formulations, they enable better wetting, coverage, and contamination removal.

- When left behind, they become a barrier to adhesion, masking as cleanliness but reducing surface energy.

Managing surfactants through measurable verification rather than relying on subjective inspection protects both product performance and production efficiency.

Next Steps for Manufacturers

If your cleaning or bonding processes depend on surfactants, it’s time to ensure those same compounds aren’t sabotaging your product quality. Download the eBook: Metrics that Matter: Quantifying Cleaning Efficacy for Manufacturing Performance, and learn how to identify and monitor every Critical Control Point that affects adhesion.

Or explore how BConnect enables you to measure, monitor, and verify surface cleanliness across your production line.

👉 Learn more about BConnect

Frequently Asked Questions

Q: What exactly is a surfactant?

A surfactant is a chemical compound that reduces a liquid’s surface tension, allowing it to spread more easily across a surface.

Q: Why are surfactants used in manufacturing?

They improve wetting and cleaning performance, making them essential in detergents, coatings, and adhesives.

Q: How do surfactants interfere with bonding?

If not rinsed completely, they remain on surfaces as a thin, low-energy film that prevents proper adhesion of paints, coatings, or sealants.

Q: How can I detect surfactant contamination?

Through water contact angle measurement—a quantitative method that reveals whether a surface is clean, contaminated, or chemically altered.

Q: How does BConnect help?

BConnect automates contact angle measurement and integrates the data into your production system, allowing real-time detection of contamination and verification of surface readiness.

To learn more about identifying and monitoring all of your Critical Control Points, download our free eBook: Metrics that Matter: Quantifying Cleaning Efficacy for Manufacturing Performance.