Having the freedom to design and build to the limits of our imaginations is at the core of what makes us human. You must think outside the common practice to boost innovation and improve processes to accomplish this task.

In manufacturing, this kind of creative thinking can dramatically help build new products that solve critical problems, are more efficient, and save lives.

However, manufacturing operations that rely on legacy materials and processes frequently restrict product development and design because that's just how it's always been done.

Understanding Materials Science Enables Freedom to Innovate

Easily create new and innovative product designs by taking advantage of assembly techniques that hinge on materials science fundamentals. For example, relying on nut and bolt fasteners or even traditional sealing methods severely limits the potential to build more functional, lighter, faster, waterproof, or more durable products than previously designed. By not relying on materials that need to be traditionally fastened, product designers of electronic devices can minimize the bezel (or frame) around the glass screen and leverage adhesive bonding. As a result, there is more flexibility to increase the screen size because there is significantly more space to bond the screen to the bezel.

When manufacturing teams adopt new, available assembly tech, product development teams can lean into designing products that move beyond what was originally possible.

The 3 Critical Inputs for Successful Adhesion & Coating

To build high-performing products, you need high-performance materials that can withstand even the most stringent performance requirements. Three critical inputs must be fully controlled when using advanced materials, like composites or other high-grade materials, to guarantee optimal performance.

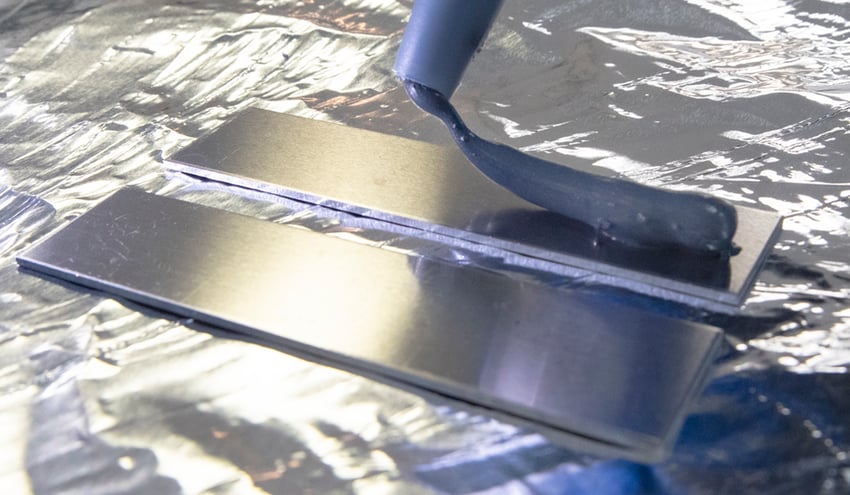

1. A thorough understanding of the chemistry you’ll apply to the material surface. Chemistry refers to any adhesive, coating, sealant, or other substance in contact with the material's surface. For assemblies to remain at high-performance levels for extended periods, it's vital to know the composition of materials applied to their surfaces.

2. The physical application and curing of the adhesive, coating, ink, sealant or paint must be fully controlled and understood to ensure the process is consistent and in keeping with the adhesive manufacturer's specifications.

3. The top molecular structure of the material surface needs to be crafted to bond perfectly with the chemistry of the material being applied. The quality of this molecular structure needs to be measured and maintained throughout the manufacturing process.

Start by defining the performance requirements of your products by applying knowledge of the material surface. This knowledge equips you to rapidly select the proper cleaning process, materials, and adhesives that are ideally suited to build the most boundary-pushing products.

For instance, one of the biggest challenges for electric vehicle manufacturers is figuring out how to design and build lighter batteries. The first step designers take to remove weight frequently is in the chassis, but these massive batteries are typically made using hundreds of pounds of fasteners alone. Instead, if the batteries were designed with high-performance materials in mind, it would remove the need for mechanical fasteners.

Rethink your adhesion manufacturing processes with Surface Intelligence.

Managing Material Surfaces Begins with Understanding Materials Sciences

The surface of your material drives the adhesives and coatings you choose and the application of each. As your product moves through the manufacturing process, the composition of the material's surface will be altered by many variables, including the air inside the assembly plant or the packaging material the product or part is placed within while it waits in inventory. A surface can be intentionally created through cleaning, activation, and preparation steps. The same surface can be reliably maintained using surface quality measurements and specifications. Using materials science knowledge, product development teams can confidently develop products whose surfaces are chemically compatible with the right type of adhesive.

The more understanding and control you have over the material surfaces, the better the adhesive and coating materials you can select. The most expensive part of an adhesive application is the adhesive or coating itself, so it's crucial to choose the ones that will meet your demands and then engineer the surface of your material to meet the quality of your adhesives and coatings.

Traditional joining or sealing methods add weight, money, and stress points. In addition, every time a fastener is used, a hole is added to the material. This means the thickness of the materials must be increased to compensate for the holes, adding weight and complexity. Adhesives are always better than mechanical fasteners when considering weight, strength, and flexibility because they allow for thinner materials, streamlined designs, and unconventional geometries.

These considerations should be handled when creating a design failure mode and effect assessment (D-FMEA) or a process failure mode and effects assessment (P-FMEA) where the risk of changing materials and processes is evaluated. Removing risk is critical to consistent and reliable process design. Risk can be mitigated through systematic and thorough testing and measurement throughout the manufacturing process to ensure that a quality surface has been created and maintained, ensuring that the final assembly will be entirely successful.

Don't Let Your Supply Chain Impact Material Surface Quality

New product development (NPD) teams must consider the substantial risk of how their supply chain will impact their material surfaces. In many instances, a development team can test and feel confident they can build the product a certain way. But if they outsource their manufacturing, the control they once had over how specific steps are performed is lost. Unforeseen process changes in manufacturing can also cause product performance issues that NPD teams didn't originally account for.

Measuring and managing surface quality determines (quantitatively) whether a change to a cleaning step, surface activation method, or another preparation step will result in adhesion failure or other performance degradation.

Scrutiny of surface quality applies to parts that are created by a supplier that arrive in the final assembly plant in an unknown condition. As a result, what appears to be clean and ready for assembly, may not be. Only through rapid, quantitative surface quality measurements can manufacturers ensure that every part is prepared for adhesives or coatings.

Surface Management Throughout the Entire Product Lifecycle

Incorporating cleanliness specifications into risk assessments creates a protective barrier around the design, allowing it to scale efficiently. It also provides for surface preparation and assembly processes to be quickly selected and qualified.

When these decisions are based on quantitative surface quality measurements, new products can scale to market faster because the risk diminishes.

These measurements add a digital record to the P-FMEA of why specific surface preparation processes were selected and demonstrate why they work well, allowing NPD teams to defend their decisions quickly. In addition, the same measurement specification can be used in manufacturing the products to ensure continuity from the development and testing stages all the way to the assembly stage.

Having a surface quality specification also allows designers to protect their designs. For example, water is a challenging variable to keep out of electronics. So instead of spending countless hours designing phones and tablets that are outwardly resistant to moisture, printed circuit boards (PCBs) are conformally coated with hydrophobic coatings to make the internal electronic components waterproof. By considering the surfaces of these electronics, manufacturers can rapidly select the right materials to solve persistent issues.

Product design can flourish and expand when manufacturing processes are keyed into surface cleanliness and control of the quality of their surfaces.

Optimize the power of next-gen connectivity with data & surface intelligence.

Shifting From Old Materials and Processes to New Materials and Processes

Shifting processes and materials can often come from shifting perspectives. For example, many manufacturers may look at a raw part and not think of the surface of that material as a fundamental component of that part. Shifting the perspective to include the molecular surface of the material allows for greater control over how that part can be attached to the complete assembly or how a coating can be used to enhance the function or performance of the part.

Other examples of how updating materials or processes have improved manufacturing and led to the freedom of product design include:

- Physical manipulation versus chemical manipulation - For most of the history of manufacturing, physically altering the surfaces of parts through processes like sanding or washing was the only option. Chemical preparations through processes such as laser etching, chemical etching, and plasma treatments are replacing or augmenting the old methods to create more precise surfaces that can be reliably bonded or coated.

- Handling procedures have drastically changed over time. Now, wearing gloves in a manufacturing setting whenever coming in contact with a part surface is standard procedure.

- Light weighting has dramatically altered both material choices and processes. Metals have been exchanged in favor of composites. Mechanical fasteners have been avoided in favor of adhesives. Thinner materials (just as strong as legacy materials) had to be developed or manipulated in new ways to replace former materials.

- Product trends for devices with touch screens have called for novel materials and processes. For example, using oleophobic coatings for touch screens prevents fingerprints and smudges on the display glass. However, using these coatings requires design teams to establish new techniques for characterizing and qualifying which type of coating will perform the best and for the most extended amount of time.

Materials science and technology enable product developers to design products with freedom. Quantitative surface quality measurements are the mechanism to both create assembly specifications and drive manufacturing validation to ensure the product is built to specification.

To learn more about significant risks that stem from a lack of surface quality control, download the eBook "The Advanced Guide to Transforming Product Development Through Surface Intelligence Data & Technology."